Our Precision Jig Trays for micro-size electronic components are crafted using cutting-edge photo etching and diffusion bonding technologies, redefining precision, efficiency, and quality control . Tailored to your unique component specifications, our Union Tray® Jig Trays deliver unmatched precision, eliminating errors, and optimizing production. Engineered for durability with diffusion bonding, our trays excel in demanding production environments, ensuring long-lasting performance. Benefit from superior dimensional stability with our Jig Trays, a critical feature for micro-size electronics production. Seamlessly integrating into automated lines, our Jig Trays reduce setup time and significantly boost productivity. Experience impeccable quality control through precise handling, guaranteeing that every component meets your exacting standards.

Advantages of Jig Trays by Diffusion Bonding

- Unmatched Precision &Customization

Photo etching allows for intricate and precise designs, ensuring that each processing jig tray can be tailored to meet the exact specifications and requirements of your components. - Cost-Effective

The absence of expensive molds or tooling reduces initial setup costs, making it a cost-effective solution for both prototyping and mass production. - Durability

The combination of materials and bonding techniques ensures that the processing jig trays have a long lifespan and can endure harsh manufacturing environments. - Short Lead Times

Photo etching and diffusion bonding processes are relatively quick, allowing for shorter lead times in production, which is crucial for time-sensitive projects. - Dimensional Stability

Photo etching and diffusion bonding processes maintain the dimensional stability of the processing jig trays over time, ensuring consistent and accurate results during component production. - Reduced Setup Time

The absence of specialized molds significantly reduces setup time, allowing for quicker transitions between different production runs and minimizing downtime. - Enhanced Automation

Processing jig trays designed through photo etching and diffusion bonding can be seamlessly integrated into automated production lines, streamlining the manufacturing process, reducing manual labor, and increasing overall efficiency.

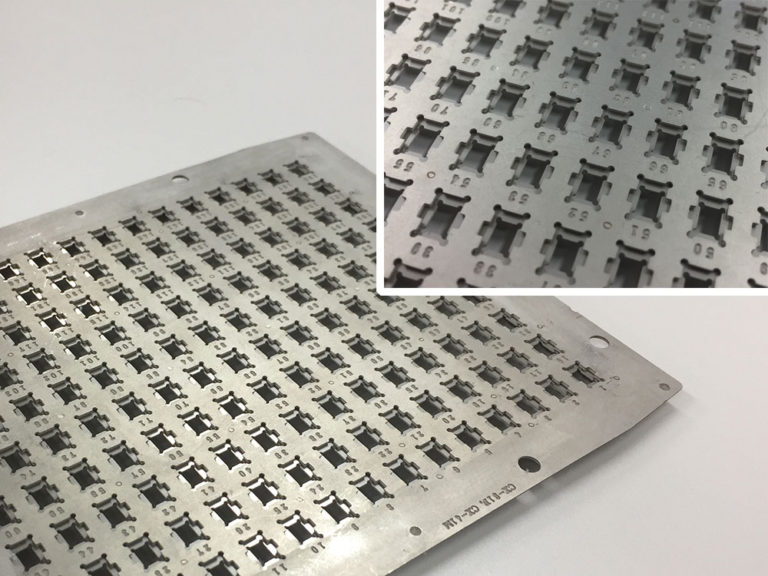

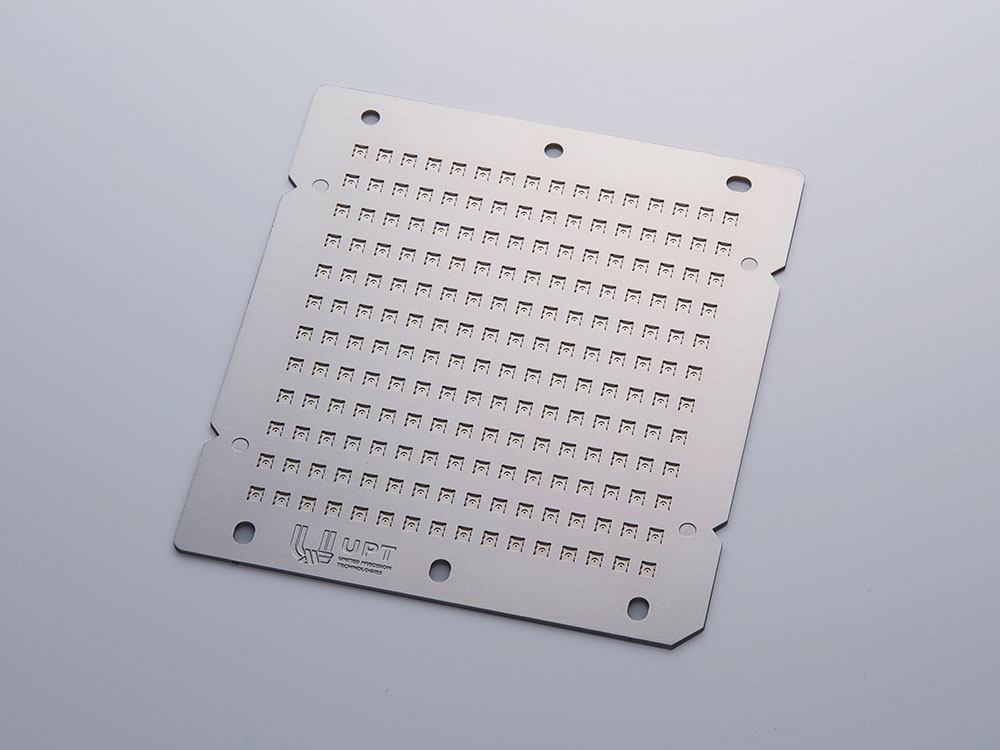

Examples

| Material | SUS304 |

| Thickness | t0.8㎜(t0.2㎜×4 layers) |

| External dimensions | 80㎜×90㎜ |

| Number of cavities | 12×14(168) |

| Hole dimensions | 1st layer Φ2.1㎜×2.5㎜ 2ndlayer Φ 1.7㎜×2.1㎜ 3rd layer Φ 0.15㎜ 4th layer Φ 0.25㎜ |

Please talk to us about your project

Since our high-precision trays are fully customizable to fit your production line, please don't hesitate to reach out to us with your ideas.