UPT Offers Custom Shims Using Advanced Photo Etching Technology

Shims are essential for fine adjustments in precision equipment. UPT manufactures custom shims to meet customers’ specifications using advanced photo etching technology. Our photo etching process provides with exceptional accuracy, combined with a variety of materials and surface treatments, allowing customers to accommodate a wide range of applications.

What are Custom Shims?

Custom order shims are shims manufactured specifically to meet the unique requirements of the customers. UPT supports from design to manufacturing, and also 2nd and 3rd processing such as surface treatments and bonding. One of our strengths is our ability to deal with both prototyping and mass production.

Advantages of UPT’s Custom Shims

UPT creates highly accurate customized base shims, to address issues on fine-tuning for equipment by photo etching technology with various surface treatments.

High Precision by Photo Etching Technology

Photo etching technology does not need force and heat to base material, resulting in a burr-free, deformation-free, and high-precision finish without dross or debris. Additional processes to remove dross or debris are not necessary, allowing for ideal thickness precision starting from 0.004mm.

Wide Range of Thickness, Material Combinations, and Surface Treatments

In the production of shim spacers, conventional metalworking methods sometimes has difficulty to make, because there are no flexibility of combination of thickness and material type. UPT, however, can handle thin sheets from 0.004mm, difficult-to-machine materials, thicker materials (up to 2mm), unique shapes, and various surface treatments. We can turn your design concepts into reality in just a few days.

Extensive Material Inventory

UPT offers a wide selection of materials and thicknesses from our extensive inventory. Available materials include stainless steel, copper, brass, iron, and aluminum. For stainless steel, we stock materials in 0.005mm increments. UPT can also handle materials such as titanium and magnesium.

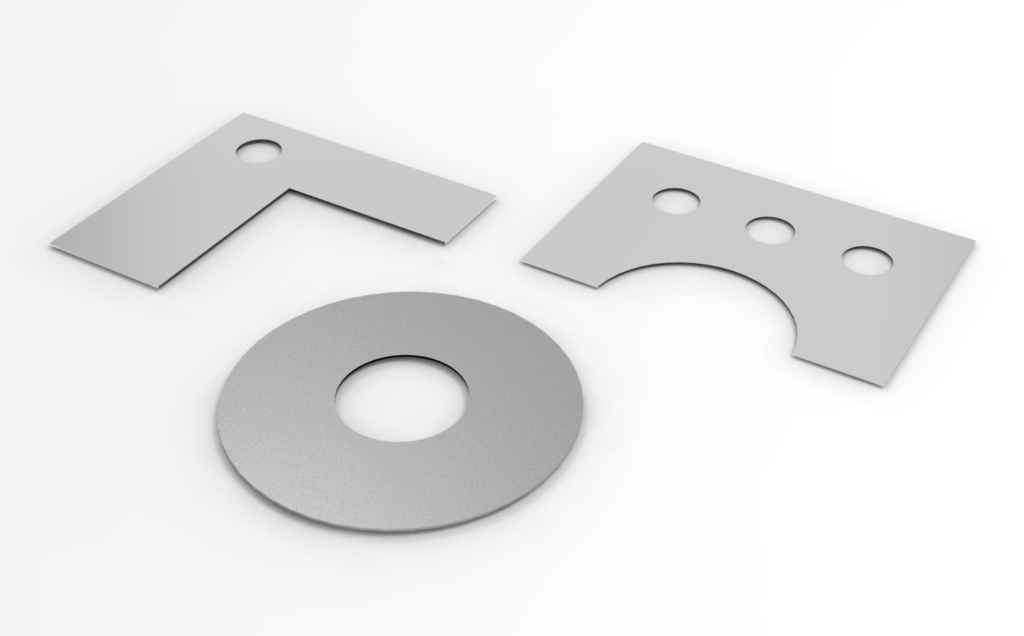

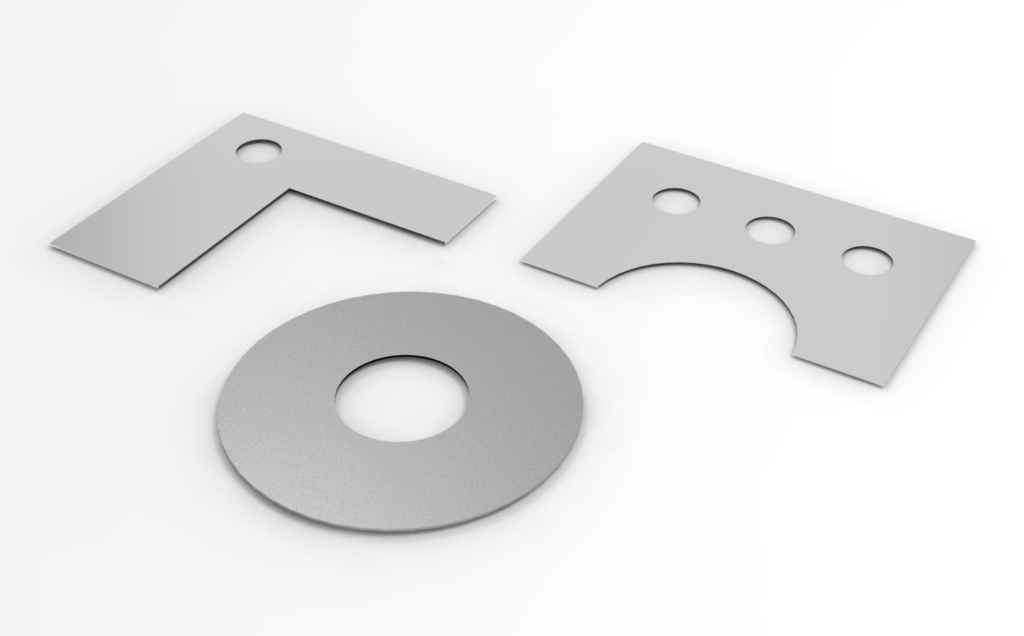

Examples of Custom Shims

Shim Spacers

Thin metal components used to adjust the position of equipment parts or fill gaps.

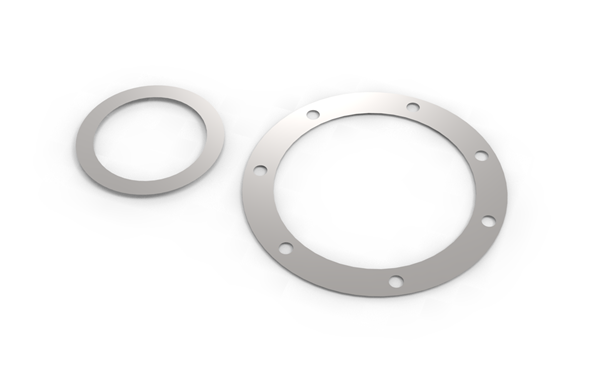

Ring / Round Shims

Ultra-thin metal rings used for fine adjustments and tolerance compensation in precision equipment. They are inserted between parts to adjust slight gaps or fine-tune positioning.

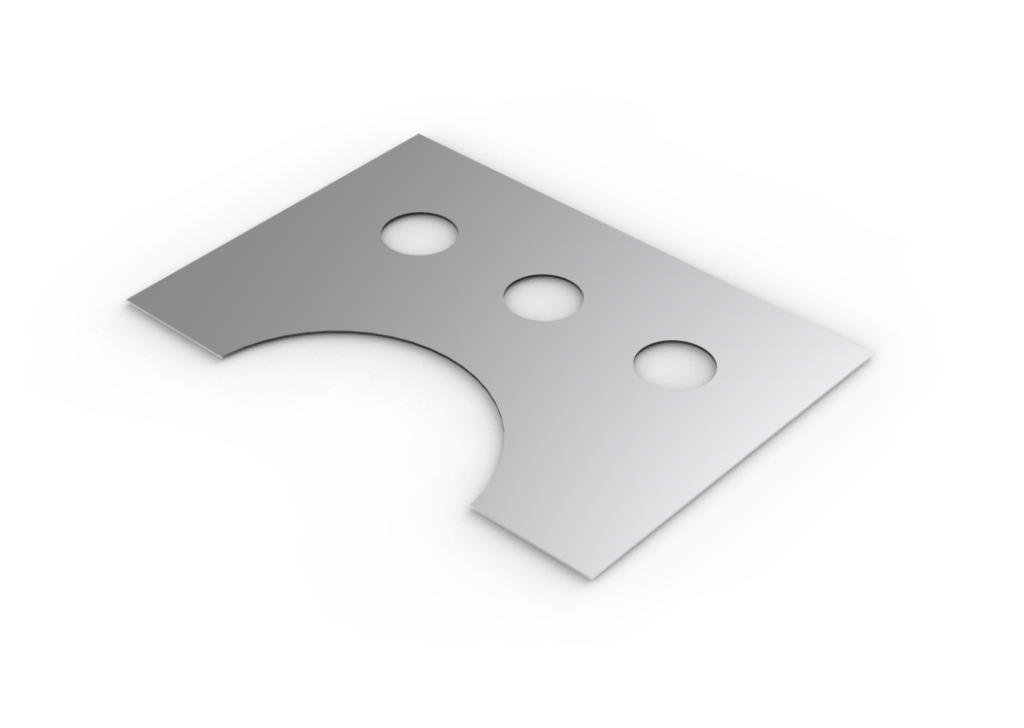

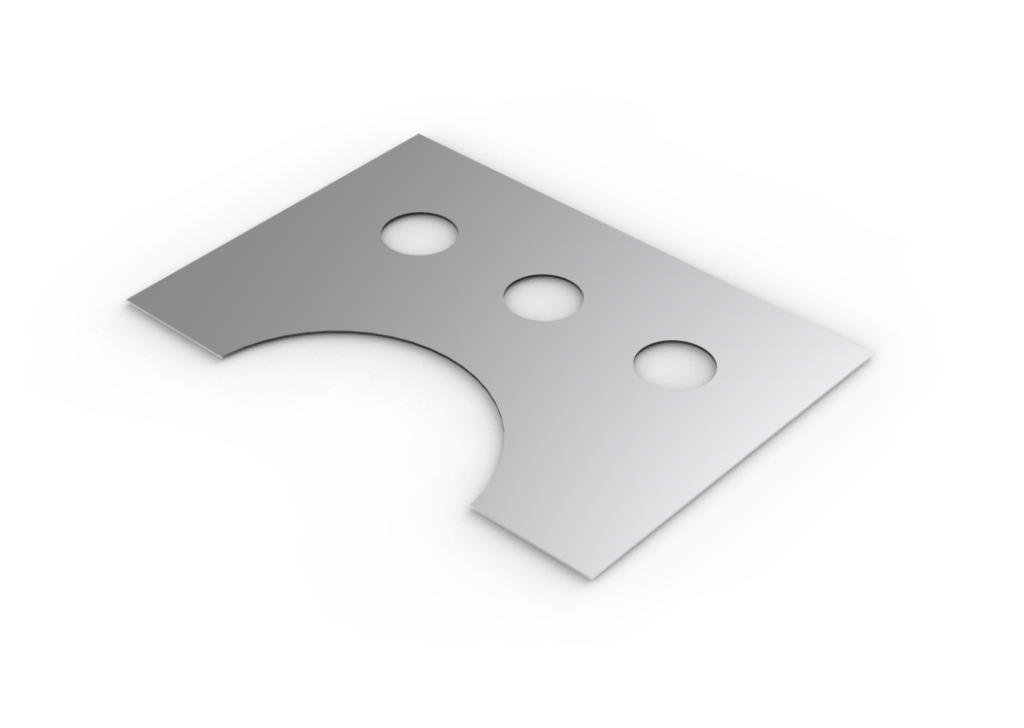

Shim Plate

Shim plates used to make fine adjustments in position or height when installing precision equipment. They play an important role in leveling equipment by absorbing slight differences in height or tilt.

Contact Us

Please feel free to contact us for a quote or technical consultation.