Diffusion Bonding Technology

Manufacturer 3D-Structured Metal Parts withDiffusion Bonding and Photo Etching Technology Diffusion bonding te […]

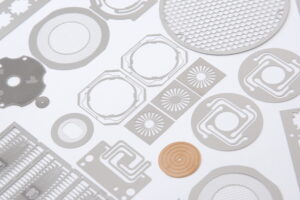

Photo Etching Technology

Smallest, Thinnest, and Finest UPT’s Photo Etching Technology Support the Hard-to-Process Materials, and Uniqu […]

Photo-Etching of Magnesium Alloys

The increasing demand for magnesium alloys stems from their immense potential for versatile applications acros […]