Adjust Tolerances and Cumulative Errors around Bearings and Roatating Mechanisms

Precision equipment assembly requires precise gap adjustments between components. High-precision ring / round shims are required to absorb tolerances and cumulative errors around bearing and rotating mechanisms at the micron level.

What are Ring / Round Shims?

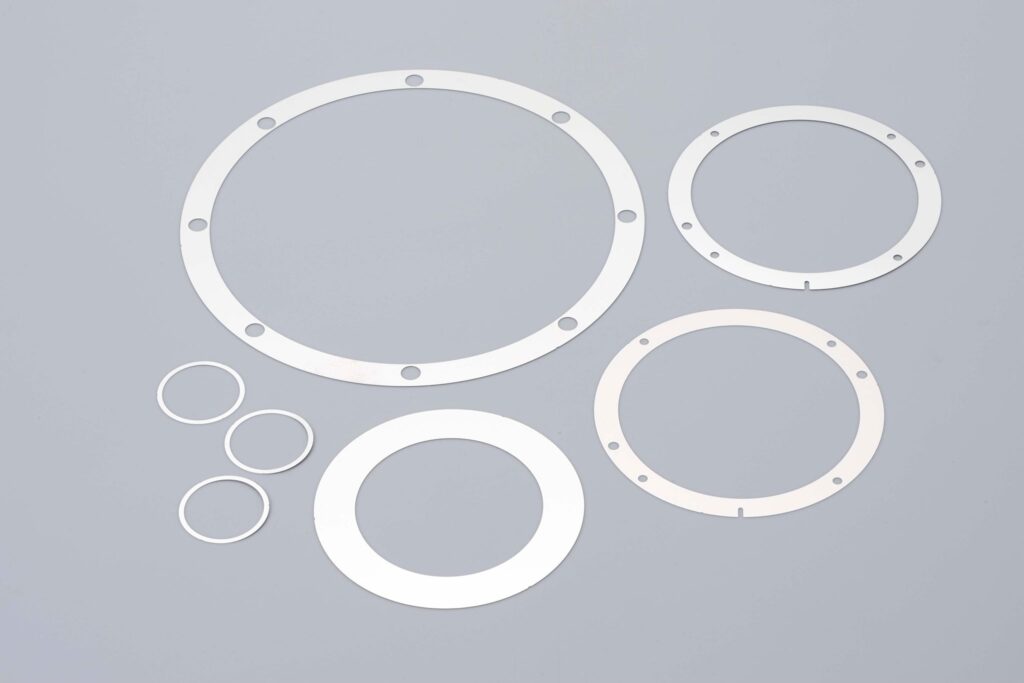

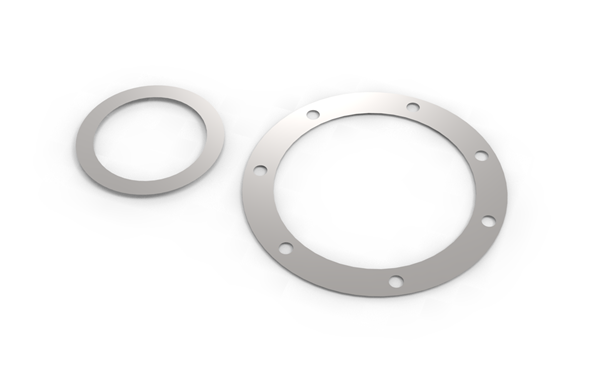

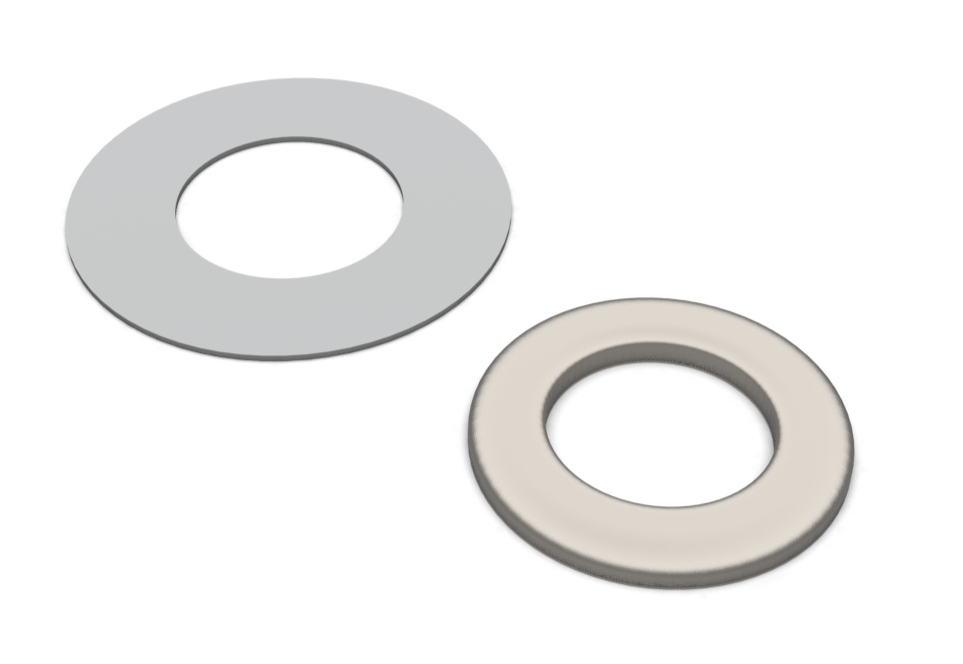

Ring / Round shims are extremely thin metal rings used for fine adjustments and tolerance absorption in precision equipment. Ring / Round shims are inserted between mechanical components to adjust slight gaps and fine-tune component positioning.

For instance, they are used to absorb cumulative errors between components of bearings and rotating mechanisms, ensuring smooth operation.

The thicknesses of ring / round shims typically are from 0.01mm to 0.1mm and made from various metals, such as stainless steel, copper, brass, iron, and aluminum, depending on the application.

Advantages of UPT’s Ring / Round Shims

UPT specializes in addressing fine-tuning challenges in precision equipment by combining photo etching technology with various surface treatments, which contibutes to manufacturing highly accurate custom shim spacers.

High-Precision Finish by Photo Etching Technology

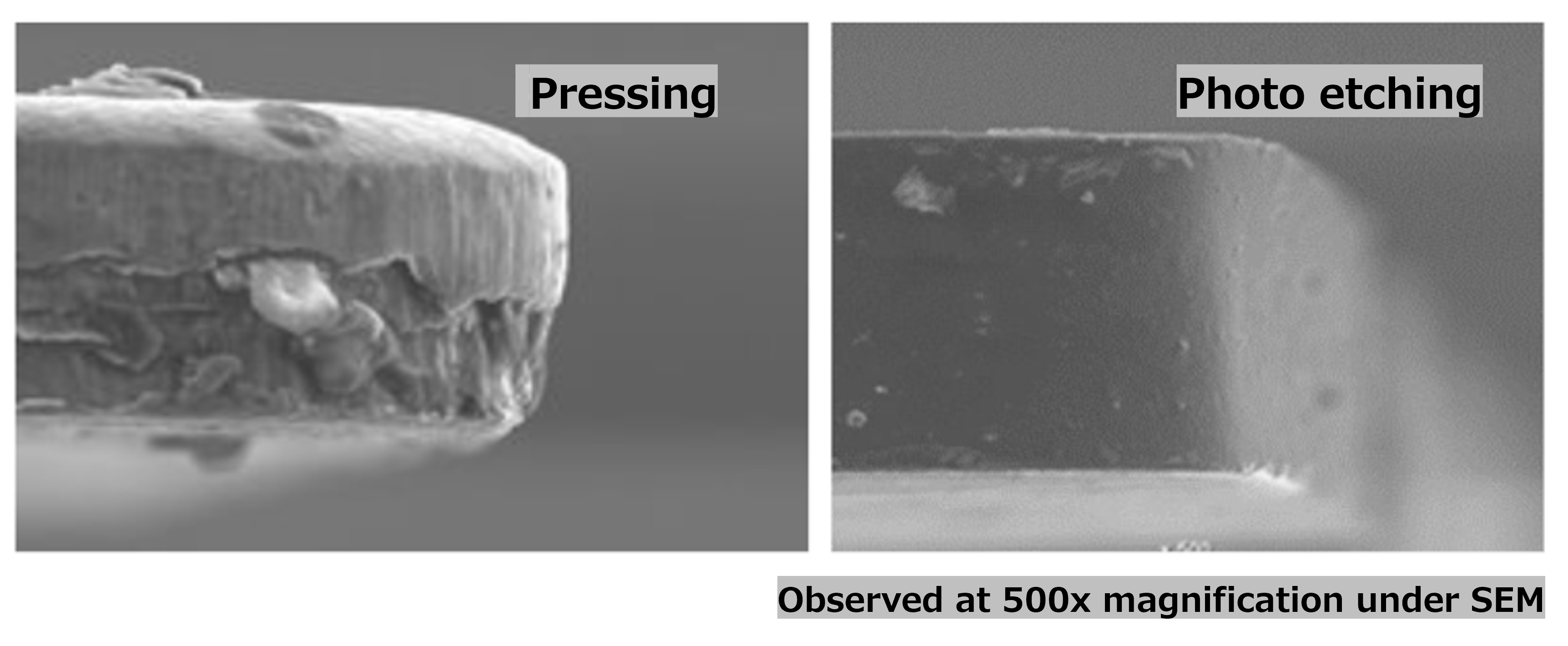

Photo etching technology needs no force and heat to base material, resulting in a burr-free, deformation-free, and high-precision finish without dross or debris. It is an ideal processing method for ring / round shims as it can deal with fine adjustments and complex shapes.

Handling Thickness, Material Combinations, and Surface Treatments

UPT can process thin sheets from 0.004mm thick. UPT meets various customer demands, including unique material combinations and black oxide finishes. If you ever wonder, ‘Can this specification be realized?’ please feel free to consult with us. UPT offers a one-stop service from photo etching to surface treatment, which enables us to deliver in short lead times. You can rely on us for processing special materials, difficult-to-machine materials, and small lot sizes.

Extensive Material Inventory

UPT offers a wide selection of materials and thicknesses from extensive inventory. Available materials include stainless steel, copper, brass, iron, and aluminum. For stainless steel, we stock materials in 0.005mm increments. UPT can also handle materials such as titanium and magnesium.

Applications and Uses of Ring / Round Shims

Ring / Round shims are used to adjust slight gaps and fine-tune the positioning between mechanical components. Here are some specific examples.

Bearings and Rotating Mechanisms

Ring / Round shims are used to absorb cumulative errors between components that make up bearings and rotating mechanisms, ensuring smooth operation. By inserting a ring / round shim between mechanical components, you can adjust gaps and fine-tune component positioning.

Measuring Instruments

In high-precision measuring instruments, precise positioning of components is crucial. Using a ring / round shim allows you to adjust gaps and positioning between components at the micron level, ensuring measurement accuracy.

Optical Equipment

In optical equipment, ring / round shims are used for lens and mirror position adjustments. Shim rings allow for fine optical path adjustments, optimizing optical performance.

Similar Products (Washers) and Other Processing Methods (Pressing and Laser Processing)

Washers

Ring / Round shims are much thinner and allow for more precise adjustments compared to washers, making them particularly effective in situations requiring fine gap or position adjustments. Shim spacers are often customized to meet specific mechanical requirements, allowing for the selection of the most suitable material and shape for a particular application. In contrast, washers are typically provided in standard sizes and shapes, offering less flexibility.

Other Processing Methods (Pressing, Laser Processing)

Ring / Round shims are manufactured with photo etching technology offer higher precision compared with other methods such as pressing or laser processing, allowing for the accurate reproduction of complex shapes and fine details. This advantage makes custom designs for specific applications more feasible. Additionally, photo etching technology applies less physical stress to the material, making it easier to keep the material properties. This technology is ideal for manufacturing thin materials or very small parts, facilitating the mass production of precision ring / round shims.

Use-Case of UPT’s Ring / Round Shims

UPT had solved problems related to cumulative errors around bearings and rotating mechanisms in precision equipment.

Optical Ring / Round Shims for Cameras (Material: SUS304 + Black Oxide Finish, Thickness: 0.01mm)

Customer’s Challenge

The customer could not find a company that could handle both the production of ring / round shims and surface treatments, thus suffered from managing multiple suppliers.

UPT’s Proposal

UPT handled an integrated process from photo etching to black oxide finishing, shortening lead times.

Additionally, by performing black oxide treatment on entire sheets instead of individual ring / round shims, UPT significantly reduced the customer’s costs too.