Allow for Leveling and Height Adjustments of Foundation for Equipment Installation

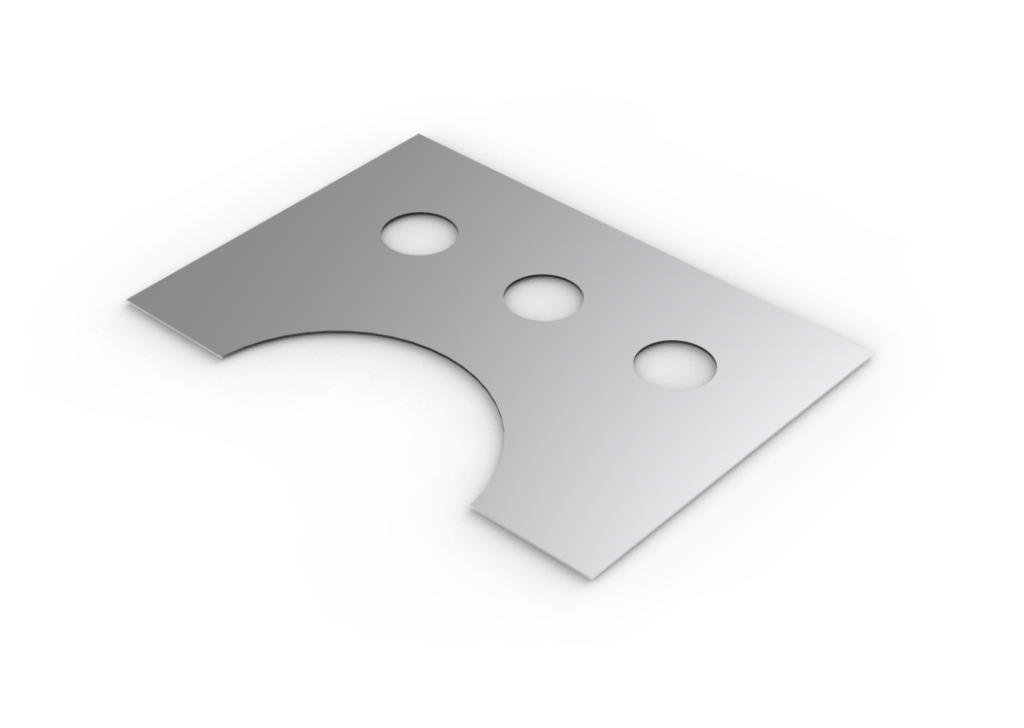

Shim plates are thin metal plates used to make fine adjustments to the position or height of precision equipment during installation. They play a critical role in absorbing slight gaps or inclinations between equipment and its foundation to maintain levelness.

What are Shims Plates?

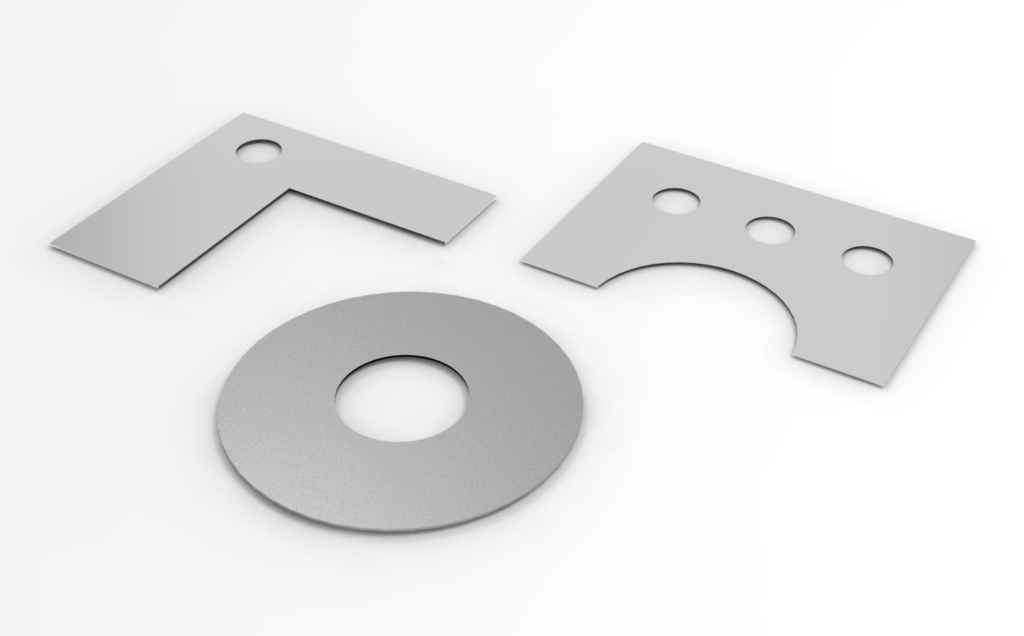

Shim plates are thin metal plates designed to adjust the tilt or height of precision equipment during installation. They are also used when the installation surface is uneven or when equipment weight causes surface irregularities. Since customers can select thickness in micron increments, shim plates are used for precise positioning, vibration absorption, and more. Depending on the application, cutomers can select from various materials such as stainless steel, aluminum, and copper alloys. Shim plates are essential components for stable equipment installation.

Advantages of UPT’s Shim Plates

UPT creates highly accurate customized shim plates, to address issues on fine-tuning for equipment by photo etching technology with various surface treatments.

High-Precision Finish by Photo Etching Technology

Photo etching technology does not need force and heat to base material, resulting in a burr-free, deformation-free, and high-precision finish without dross or debris. Additional processes to remove dross or debris are not necessary. UPT offers ideal thickness precision starting from 0.004mm.

Handling Thickness, Material Combinations, and Surface Treatments

Conventional metalworking methods sometimes have no flexibility of combination of thickness and material type.

Additionally, for specialized applications such as optical components and devices, black coating or black oxide treatment may be required to suppress light reflection and stray light.

UPT offers a one-stop service, from photo etching to surface treatment, handling various thicknesses and material types.

Photo etching technology needs no mold, reducing costs while preventing burrs and deformation.

Extensive Material Inventory

UPT offers a wide selection of materials and thicknesses from our extensive inventory. Available materials include stainless steel, copper, brass, iron, and aluminum. For stainless steel, we stock materials in 0.005mm increments. UPT can also handle materials such as titanium and magnesium.

Applications and Uses of Shim Plates

Shim plates play a vital role during machine installation. When the installation surface is not perfectly flat or when slight surface irregularities occur due to the weight of the machinery, they can be inserted to keep the machine level. Additionally, when height adjustments are necessary, they can be stacked to achieve the desired height.

For example, in semiconductor manufacturing equipment, where high precision is required,shim plates are used to ensure that the equipment is perfectly level, helping to maintain product quality. They are also used for aligning motor bases, couplings, and other applications requiring accurate leveling.

In this way, shim plates are essential for the stable installation of machinery. It is crucial to select the appropriate material and thickness of the shim in accordance with the application.

Use-Case of UPT’s Shim Plates

UPT has successfully solved problems related to cumulative errors around bearings and rotational mechanisms of precision equipment.

Shim Plates for Semiconductor Manufacturing Equipment (Material: SUS304, Thickness: 0.01mm)

Customer’s Challenge

The customer used laser processing for shim manufacturing, which was unsuitable for thin sheets, thus had difficulty in achieving the desired thickness and shape.

UPT’s Proposal

UPT manufactured custom shims with thickness options starting from 0.004mm with photo etching technology.