Fine slit processing with etching technology maximizes resolution

Optical rotary encoders are sensors detect the position of servomotors and enable position measurement with extremely high accuracy. UPT helps design and manufacturer discs and scales for optical rotary encoders. Please contact us if you have any problems such as insufficient resolution, delivery time, or cost with existing methods.

About Optical Rotary Encoder

Optical rotary encoders detect the position of servomotors and measure position with very high accuracy.

These encoders have two types, incremental and absolute, each with different characteristics.

While the incremental type detects the rotation angle as a relative position and has a relatively simple structure, the absolute type converts the rotation angle into an absolute position signal and provides accurate position information.

The absolute type is especially for situations where high-precision operation is required.

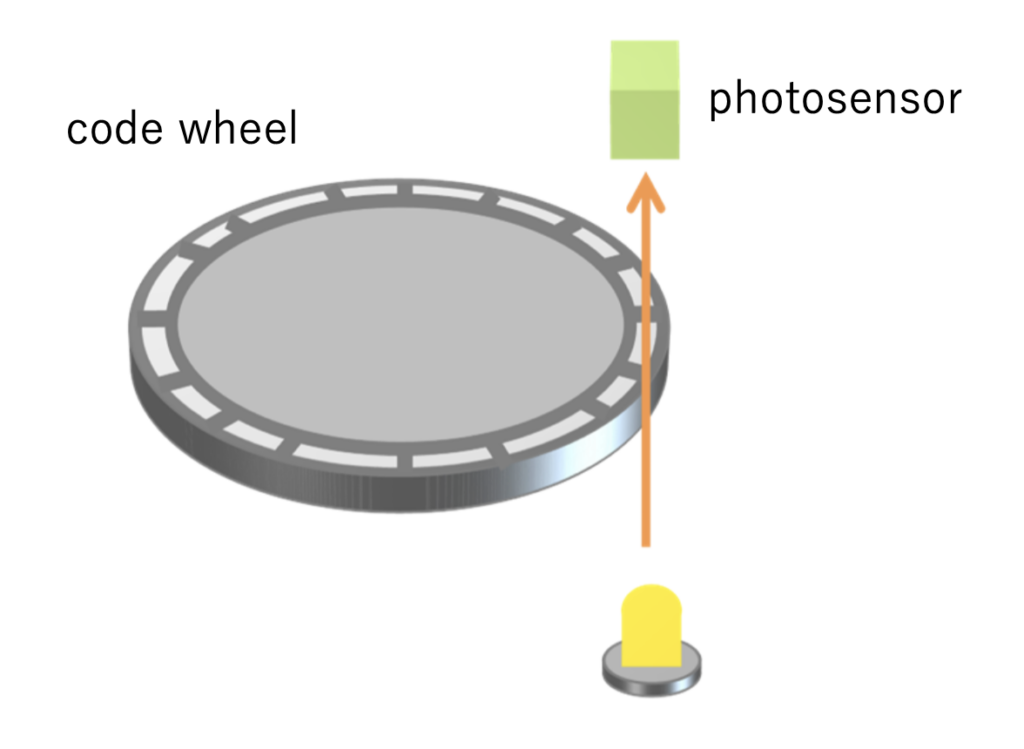

Inside the optical encoder are light emitting elements such as LEDs and laser diodes, and light receiving elements that detect light. Between these elements, a code wheel mounted on a rotating shaft is incorporated. The cord wheel has a fine slit formed on it, and light passes through this slit to generate an optical pulse signal.

By analyzing the optical pulse signal, the rotation angle and position of the motor are detected. The optical method provides high resolution and responsiveness, and is used in many industrial applications.

Fine slit processing technology maximize resolution

| specification | content |

|---|---|

| material | any etchable metal (excluding tungsten, gold and silver) |

| thickness | available in any thickness(0.004mm~) |

| accuracy | ±10% of plate thickness (MIN Tolerance ±0.01mm~) |

| surface treatment | various surface and black treatments are available |

Examples of discs and scales for optical rotary encoders

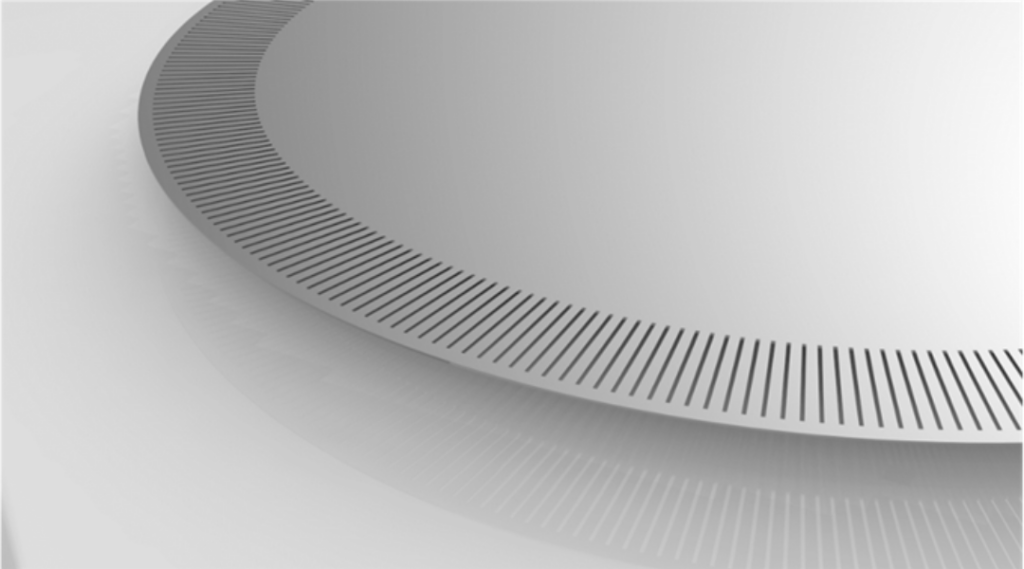

encoder disc

material : SUS304

thickness : 0.08mm

method: etching

slit width : 110μm

size : 49φ

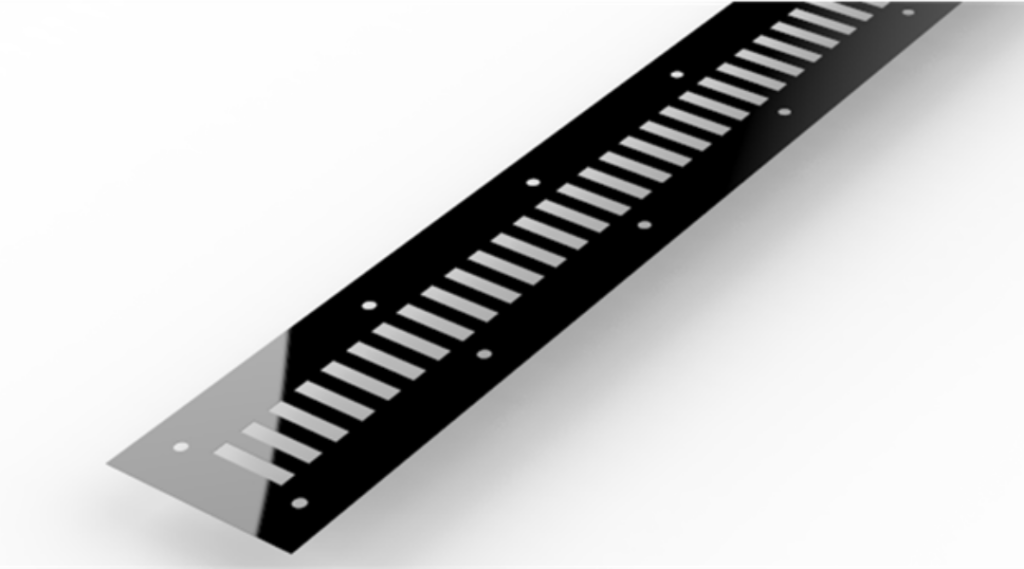

linear scale

material : SUS304

thickness : 0.1mm

method: etching

surface treatment : black

plating slit : width 3mm / 6mm pitch

size : 40mm x 370mm

Use-cases

Industrial Robot

Optical encoders dected position of industrial robots joints and axes.

The incremental type controls high-speed rotation, while the absolute type provides accurate position control, enabling high-precision operation. This features support high-precision work in automated assembly and welding robots.

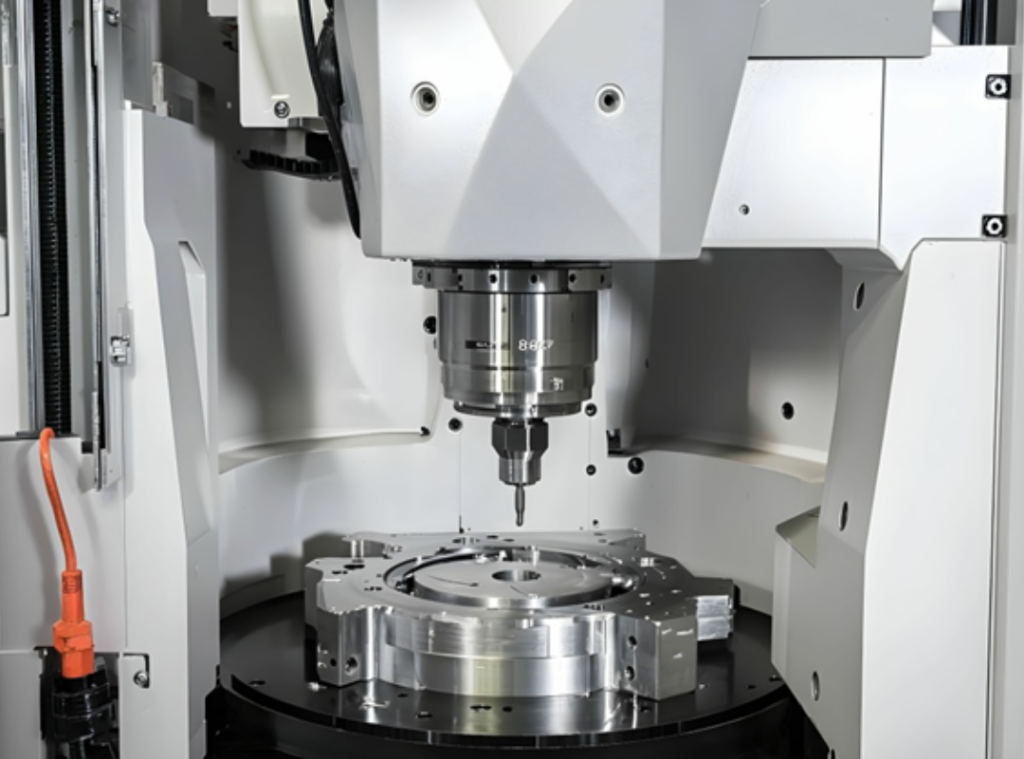

machine tools

Encoders detect the position of rotating and moving axes in machine tools such as lathes and milling machines. Their high resolution increases the precision of cutting, and improves quality and efficiency.

medical equipment

Encodrs are indispensable for precise motion control of medical equipment such as CT scanners and surgical robots. Absolute encoders ensure safe and accurate motion in medical applications where precision is mandatory.

automobile

Used for rotation control of electric power steering and in-vehicle motors.

Highly accurate angle detection improves vehicle safety and comfort.

Leave it to UPT to design and manufacture discs and scales for optical rotary encoders!

UPT can design and manufacture discs and scales for optical rotary encoders.

Please contact us if you are facing problems such as insufficient resolution, delivery time, or cost with existing methods.