UPT specializes in manufacturing wheel encoder discs for optical rotary encoders. If you’re facing challenges with your current methods, such as insufficient resolution, long lead times, or high costs, please don’t hesitate to contact us.

What is wheel encoder discs?

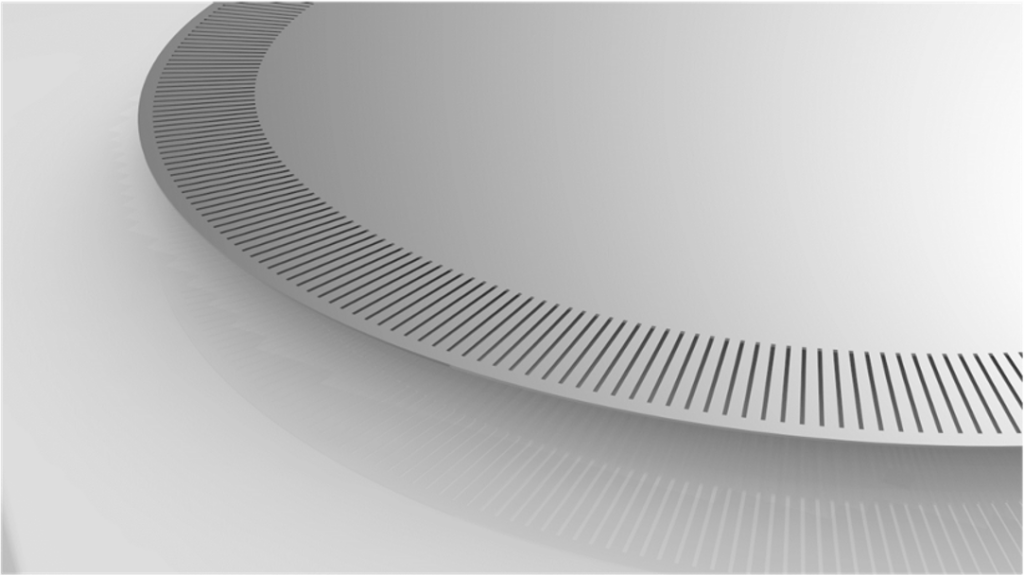

Encoder discs are sensor components used to measure the position and speed of rotation. They are mainly used in industrial equipment, robots, and precision instruments. Discs are etched with graduations or patterns. As they rotate, optical or magnetic sensors detect these changes and generate signals. These signals are then used to calculate the rotational angle or speed of the machine.

One technical approach to improving the performance of optical encoders is increasing the resolution. While resolution can be enhanced by increasing the number of slits on the encoder’s code wheel, this requires advanced processing technology and high precision in manufacturing, as the slit width decreases with a greater number of slits within the same area.

Manufacturing example: Wheel encoder disc

Product Specifications

Material: SUS304

Thickness: 0.08mm

Process: Etching

Slit width: 0.11mm

Size: φ50mm

Leave it to UPT to design and manufacture discs and scales for optical rotary encoders!

UPT has advanced etching technology that minimizes warping and distortion of metal foil. This technology enables the production of scales free from problems such as burrs, and high dimensional accuracy with a plate thickness tolerance of ±10%.

| Specification | Content |

| Material | Any etchable metal, excluding tungsten, gold and silver) |

| Thickness | Available in any thickness from 0.004mm~ |

| Accuracy | ±10% of plate thickness (Minimum Tolerance ±0.01mm~) |

| Surface Treatment | Various surface treatments including black tretment are available |