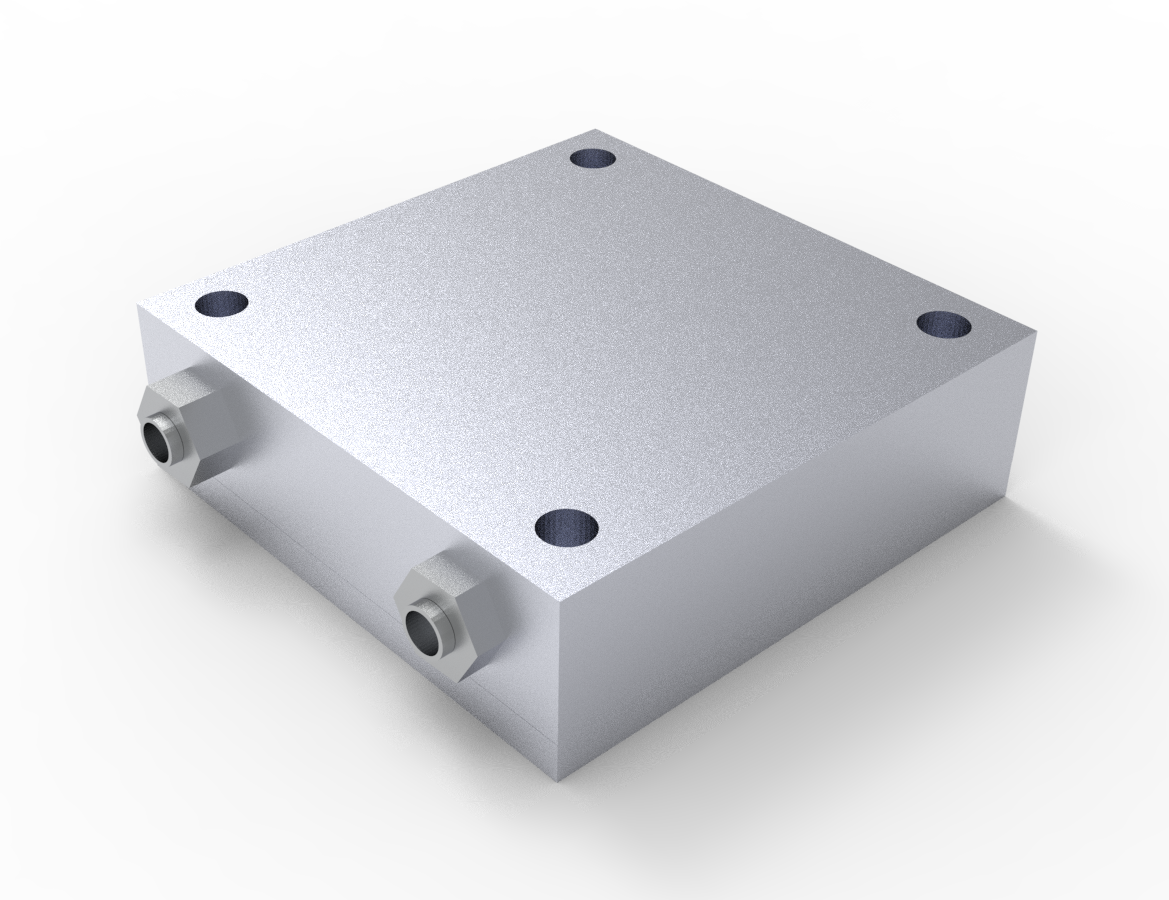

Cold Plate with Excellent Thermal Conductivity, Lightweight Properties, and Cost Advantages

Aluminum cold plates offer an excellent balance of light weight, thermal performance, and cost, making them widely used across various industrial applications.

Although aluminum’s thermal conductivity (approx. 205 W/m·K) is lower than copper, optimized channel designs enable sufficient cooling performance in most practical cases.

Its superior machinability allows for complex flow paths tailored to device heat distribution. With a density about one-third that of copper, aluminum also contributes to overall equipment weight reduction.

Additionally, its relatively low material and processing costs make it suitable for mass production. When combined with corrosion-resistant alloys or anodizing, aluminum cold plates deliver stable and reliable performance across a wide range of environments.

Comparing Aluminum, Copper, and Stainless Steel Cold Plates

Selecting the right cold plate material requires considering thermal conductivity, weight, corrosion resistance, and cost. Aluminum offers a well-balanced combination of these factors, making it suitable for the broadest range of applications.

Copper, with its high thermal conductivity of around 385 W/m·K, is ideal for high-power devices that require maximum cooling efficiency. Stainless steel, while lower in thermal conductivity, provides excellent strength and chemical resistance, making it suitable for harsh environments or systems that handle special fluids.

A comparison table helps clarify the optimal material choice for each application.

| Item | Aluminum | Copper | Stainless Steel |

|---|---|---|---|

| Thermal Conductivity (W/m·K) | ~205 | ~385 | ~15 |

| Density (g/cm³) | 2.7 | 8.96 | 7.9 |

| Machinability | Excellent | Moderate–difficult | Moderate |

| Corrosion Resistance | Good (improved with anodizing) | Moderate (requires treatment) | Excellent |

| Cost | Low | High | Medium–high |

| Weight | Light | Heavy | Relatively heavy |

| Typical Applications | General electronics, automotive, telecom | High-power cooling, semiconductor tools | Chemical environments, high-strength applications |

UPT’s Core Technologies Used in Liquid Cold Plates

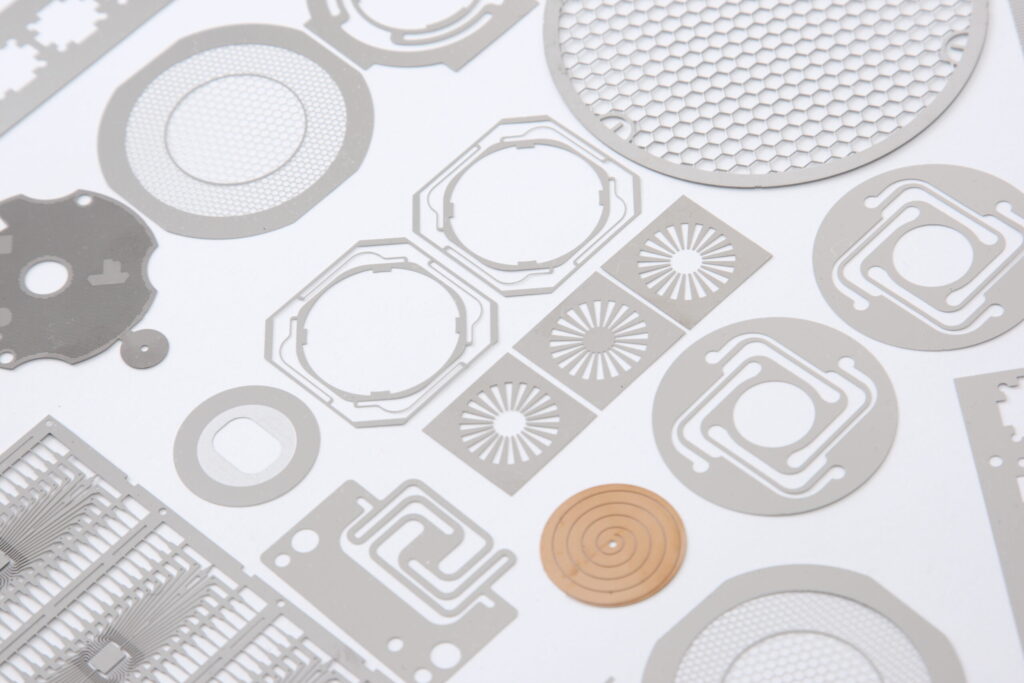

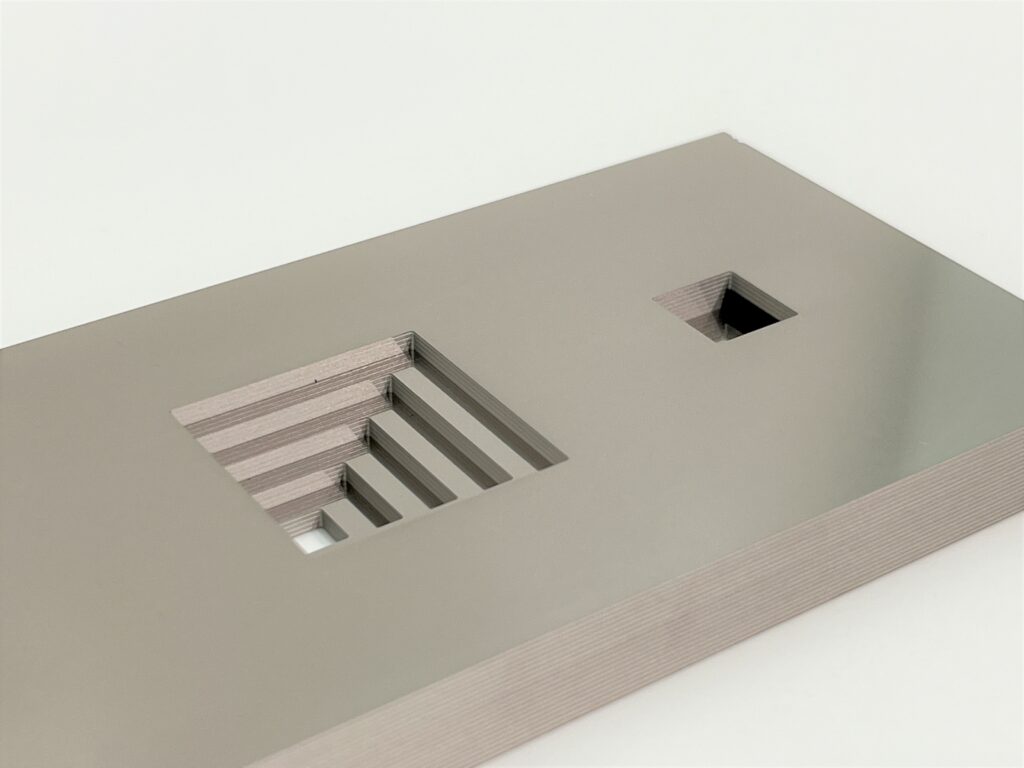

UPT combines photo etching and diffusion bonding technology to manufacture cold plates. This combination offers superior heat dissipation and design flexibility compared with other methods.

Photo etching is the process of using corrosive chemicals to melt specific areas on a metal sheet, resulting in precise, unique and intricate metal parts. This allows for the formation of complex channel structures, enhancing the thermal dissipation efficiency of the coolant.

Diffusion bonding is a bonding technique that joins metals at the atomic level by bringing their surfaces close together. It allows for the highly precise creation of metal parts with complex 3D internal structures. Adhesives and spot welding are also commonly used to bond metals, but these techniques have drawbacks such as cleaning difficulties, peeling at high temperatures, and leaving gaps. The combination of photo etching and diffusion bonding technology produces high cooling performance.

Use Cases of Cold Plates

UPT has solved thermal issues in various fields. Here are some examples:

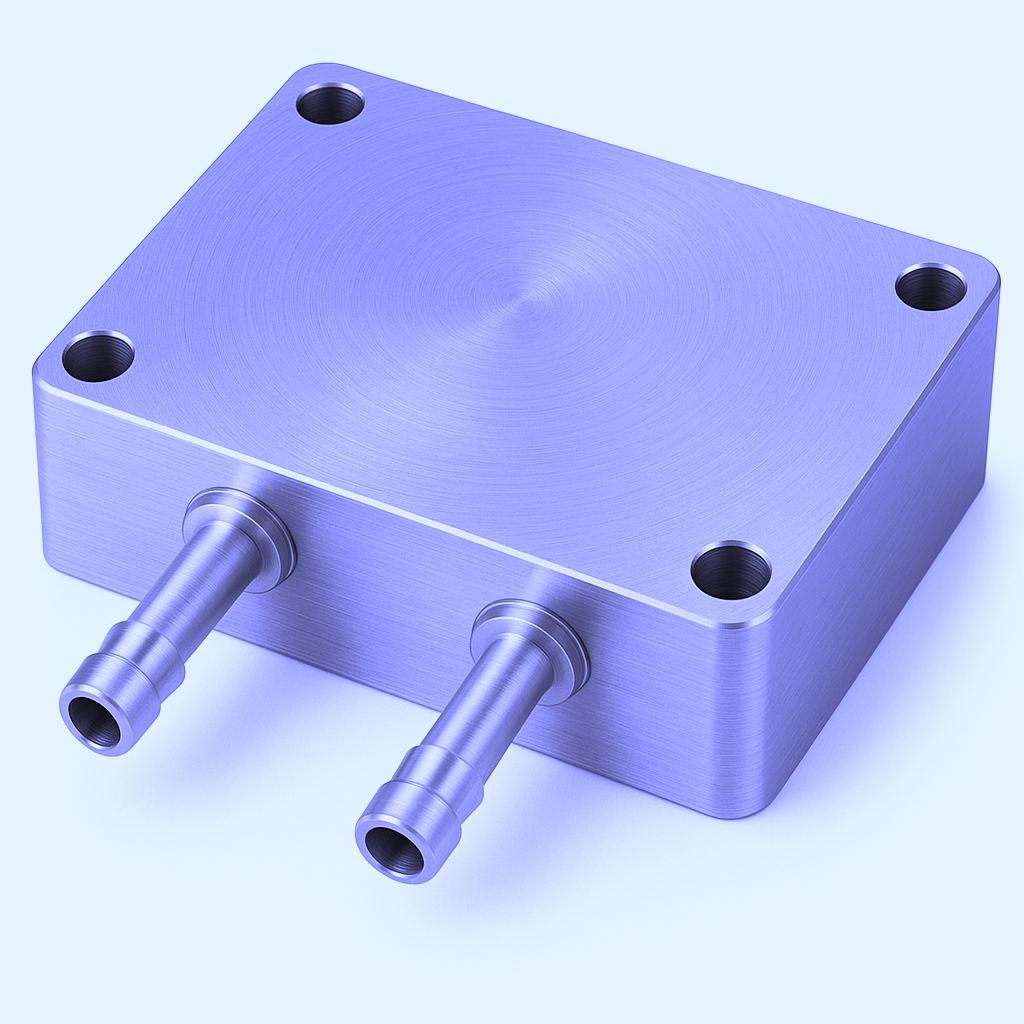

Use Case: Cold Plates for Robotics Applications

Customer Challenge:

Because the robots are constantly in motion, the customer wanted cold plates made from lightweight aluminum. With the conventional air-cooling method, the robots frequently overheated and had to be stopped regularly for cooldown.

UPT’s Solution:

By adopting UPT’s cold plates, the robots can now operate continuously without needing downtime for cooling.

Custom Cold Plate Designs

UPT offers custom-designed cold plates. Please contact us if you are facing challenges such as insufficient cooling capacity or limited design flexibility with your current methods.