Semiconductor devices and electronic components generate significant heat during operation. Efficient removal of that heat is essential to maintain device performance and extend lifetime.

At UPT, we specialize in designing and manufacturing cooling solutions—using high-thermal-conductivity metals and advanced internal flow-path structures to deliver optimal heat dissipation.

Key Features of Microchannel Cold Plates

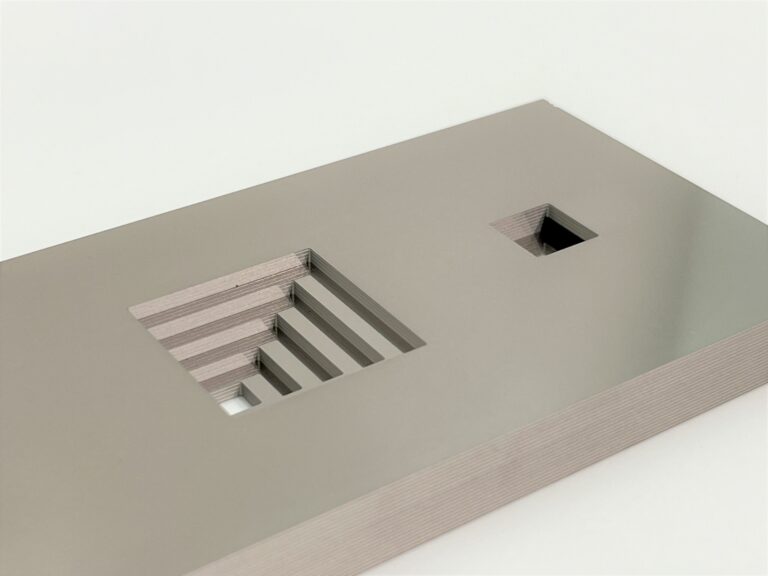

Microchannel cold plates are designed with densely packed, fine-flow channels engineered to maximize heat transfer efficiency. By significantly increasing the internal surface area that comes in contact with the coolant, these plates enable rapid heat absorption and superior thermal performance compared to traditional cold plates.

The micro-scale channels promote uniform coolant distribution, reduce thermal resistance, and allow for precise temperature control in high-heat applications such as semiconductor processing and power electronics. Their compact structure also supports lightweight, space-efficient thermal designs without sacrificing performance.

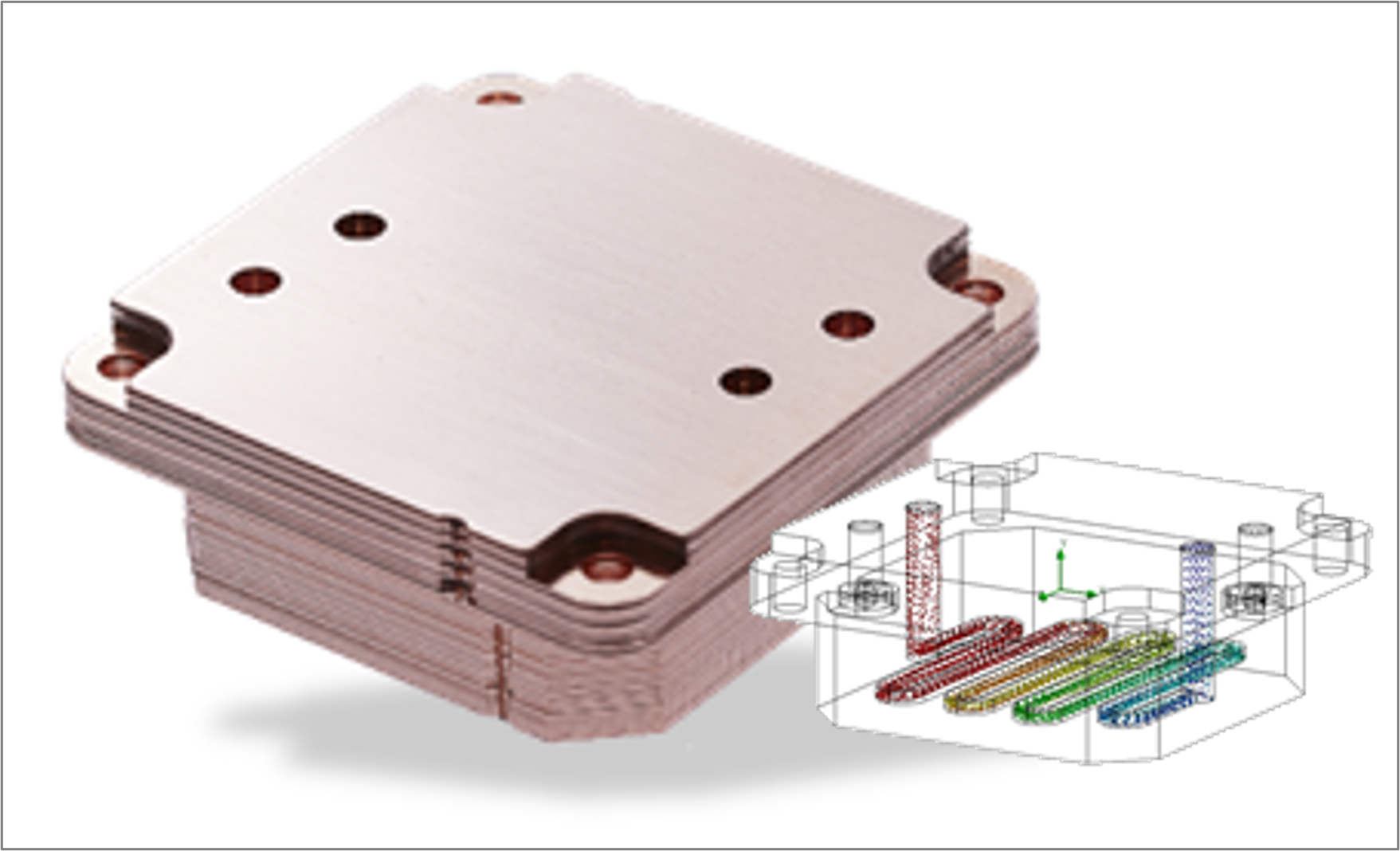

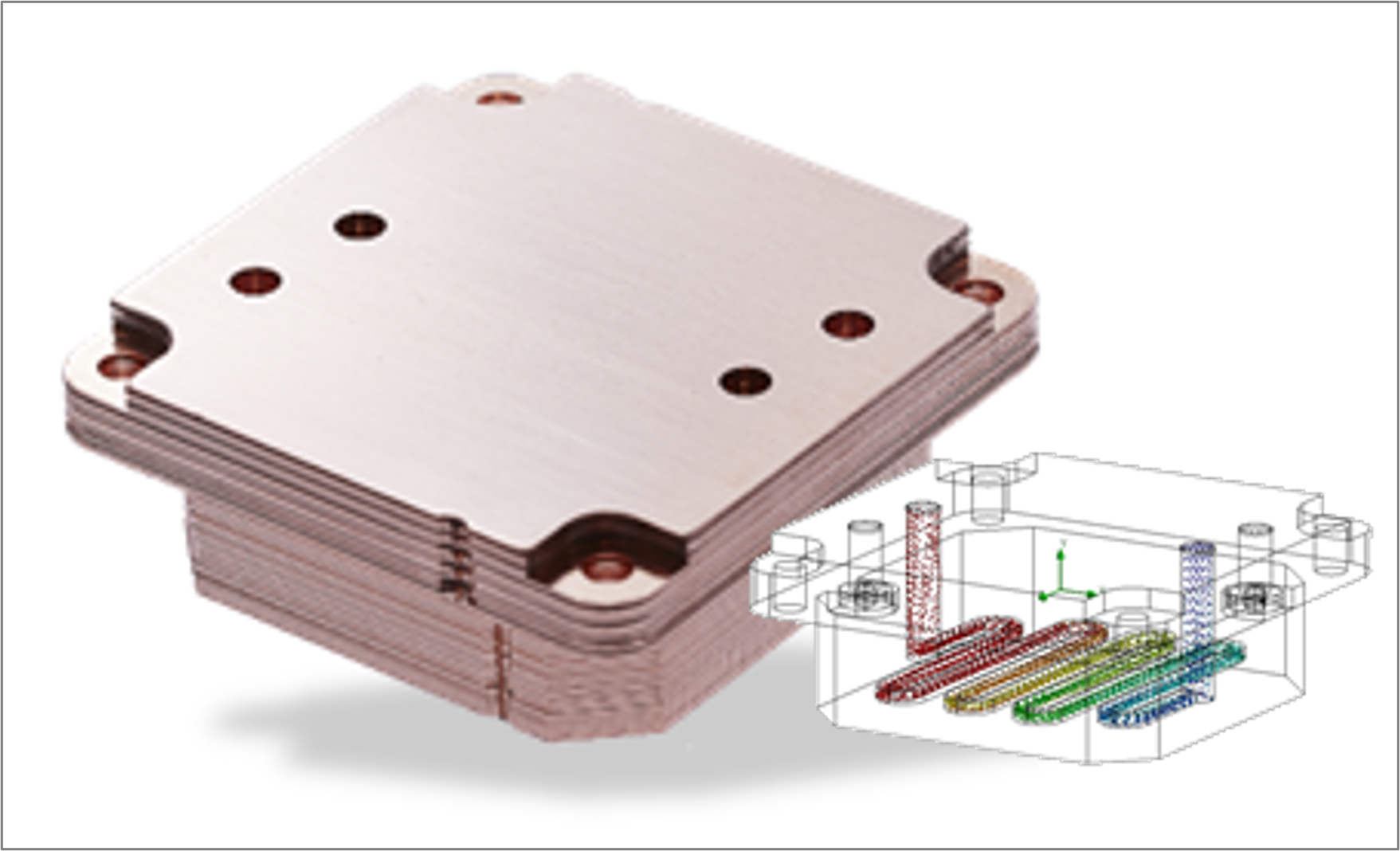

Case Study: Cold Plate for Semiconductor Manufacturing Process

Here, we present a concrete example of a cooling plate manufactured by UPT, tailored for semiconductor process cooling. The design leverages internal complex flow paths and high-performance manufacturing techniques to achieve superior heat dissipation.

Material: C1020 (copper)

Thickness: 10 mm

Manufacturing method: Photo-etching and diffusion bonding to create internal flow paths

Typical lead time: Within three weeks after order (depending on the flow-path pattern)

Application: Cooling for semiconductor testing handlers

Why Choose a Microchannel Cold Plate From UPT

At UPT, we combine advanced manufacturing techniques—specifically photo-etching and diffusion bonding—to realize complex internal flow path designs that are difficult or impossible with conventional machining. This enables the creation of microchannel cold plates that offer superior thermal performance.

Photo-Etching Technology for Complex and Micro-Scale Designs

Diffusion Bonding To Create 3D Structures Not Possible With Conventional Machining

Compared to traditional cold plates, microchannel designs significantly increase the surface area for heat exchange and improve coolant flow efficiency, resulting in much higher heat transfer rates while maintaining compact form factors.

Moreover, depending on coolant type—water, glycol-based fluids, or custom coolants—UPT’s cold plates can be optimized for specific applications, offering flexibility in thermal system design.

For high-heat applications like semiconductor processing, data centers, or power electronics—where effective heat dissipation is critical—a microchannel cold plate is often the best solution.