In manufacturing and testing processes, insufficient heat dissipation can directly affect product quality and yield.

Standard cooling solutions often fail to meet the increasingly strict performance requirements, particularly when cooling performance varies between individual products.

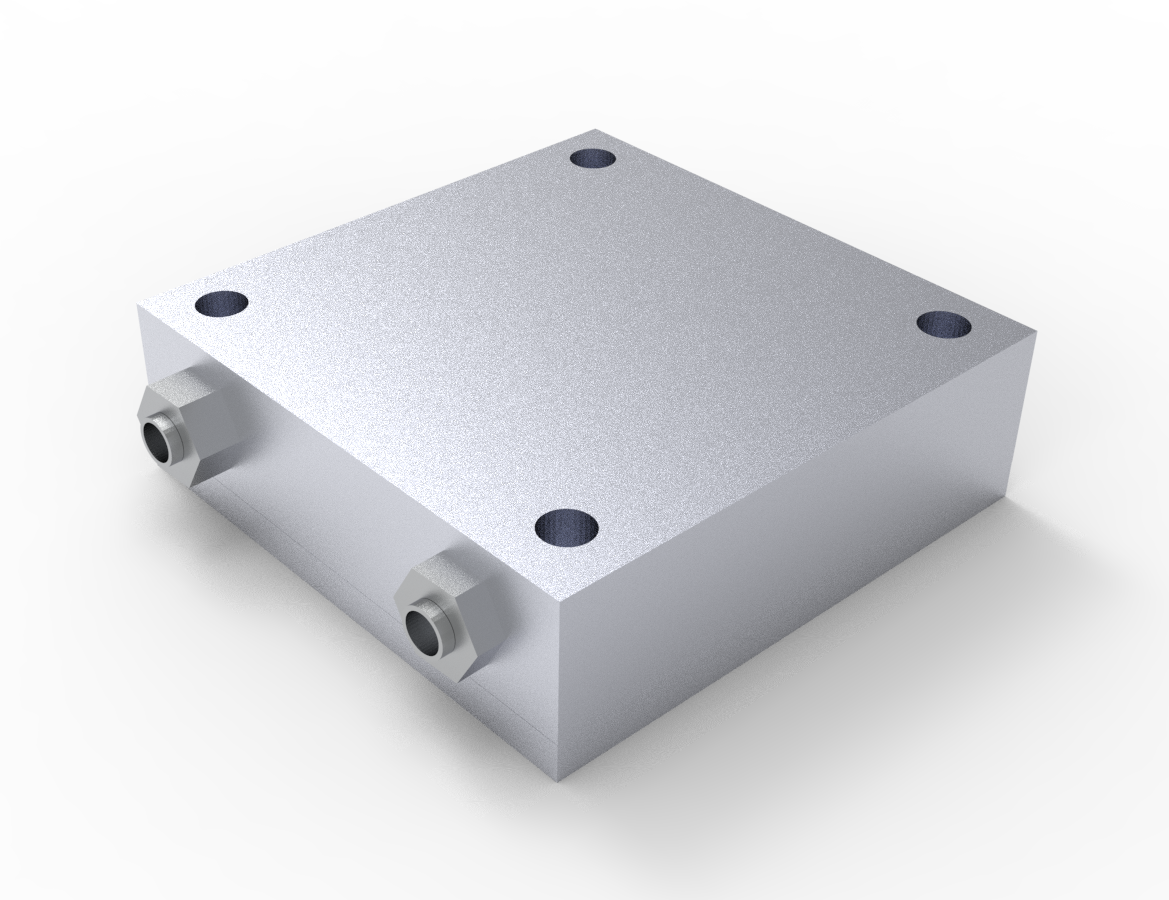

UPT provides custom-designed cold plates, optimized for each customer’s specific requirements, using advanced microfabrication technologies. This case study in the semiconductor industry introduces an example in which a customer-specific cold plate design significantly improved cooling uniformity and reduced defect rates.

Customer Challenges

The customer was an IC test handler manufacturer for the semiconductor testing process and was facing the following issues with their existing cooling solution:

- Insufficient heat dissipation performance

- Variations in cooling performance between products

- Increased defect rates during the testing process

Since the existing cold plate did not meet the required specifications, stable and efficient testing could not be achieved.

UPT’s Approach: Cold Plate Customization Based on Customer Specifications

Rather than supplying an off-the-shelf product, UPT developed a custom cold plate tailored to the customer’s specific requirements.

Detailed analysis of customer requirements

UPT carefully reviewed the operating conditions, heat dissipation needs, and installation constraints.

Optimization of internal flow channel width through simulation

UPT optimized flow channel dimensions using simulations to maximize heat transfer performance and reduce performance variation.

High-precision manufacturing

The cold plate was manufactured using photochemical etching and diffusion bonding, enabling complex internal flow paths with high dimensional accuracy.

Through this process, UPT delivered a cold plate that precisely met the customer’s required specifications.

Key Takeaway: Custom Design Over Standard Products

This case study demonstrates that the key to solving thermal challenges lies not in simply adopting a higher-performance standard product but in customizing the cold plate design to meet specific customer requirements.

By combining simulation-based design optimization with advanced manufacturing technologies, UPT was able to deliver a cooling solution that addressed the customer’s challenges effectively.

UPT’s Cold Plate Solutions

UPT specializes in custom cold-plate design and manufacturing, offering solutions optimized for each customer’s application.

From flow-channel design to manufacturing-process selection, UPT supports customers throughout the entire development process to achieve optimal thermal performance.