In semiconductor final testing, the rapid evolution of semiconductor technology has accelerated the demands for BGA sockets to accurately test high frequencies in the millimeter wave band. We at UPT have developed our original test socket “MMS” with a unique one-piece structure that enables stable and accurate high-frequency measurement as a BGA socket by reducing the number of contact points and achieving high dimensional accuracy.

What are BGA Sockets?

BGA sockets are adapters for mounting BGA package ICs in a removable state without directly soldering to the test substrate. Connecting IC’s solder balls to test board pads with a BGA socket realizes quick and flexible tests while reducing the risk of contact failures (open / short) and damage to IC.

Especially in the IC operation verification phase, BGA sockets can easily compare the performance and operating conditions of new chips, perform failure analysis, and conduct programming work, thereby contributing greatly to improving the efficiency of prototype development. They can also contribute to avoiding troublesome soldering processes again and again in an evaluation environment where ICs replaced frequently.

BGA sockets are indispensable tools for IC evaluation through development processes, but their tendencies to have complex structures, to require many board space, and thus to be expensive make them unsuitable for mass production.

Case Study: Replacing BGA sockets with “MMS”

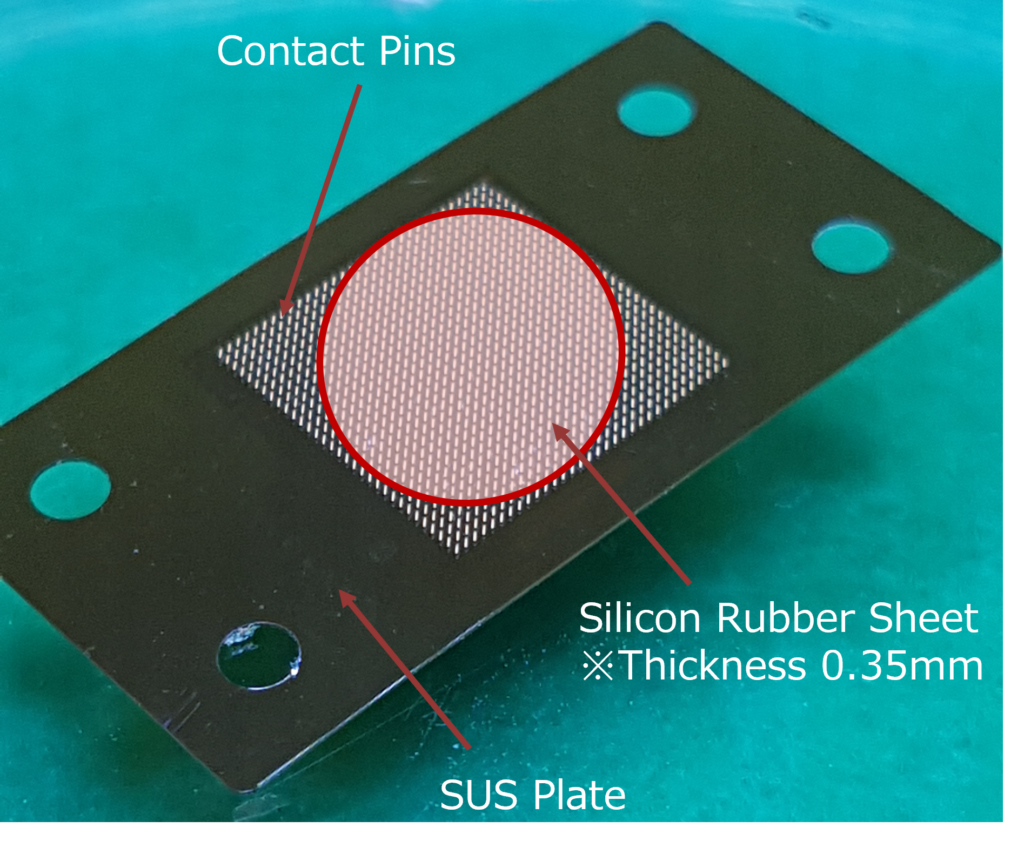

Existing test sockets have diffucult challenges in measuring contactability and high-frequency characteristics. UPT addresses them with the original “MMS” test sockets, which have a unique one-piece structure, which meets the customer’s required specifications.

Customer Issues

Stable and accurate measurement of high-frequency characteristics has become a major issue in the final test of semiconductor ICs.

Pogo pins and rubber sockets, which have been adopted as BGA sockets, often have diffuculty in ensuring the stable and accurate measurement of high-frequency characteristics due to their complicated structure caused by multiple components.

UPT Proposal and Solution

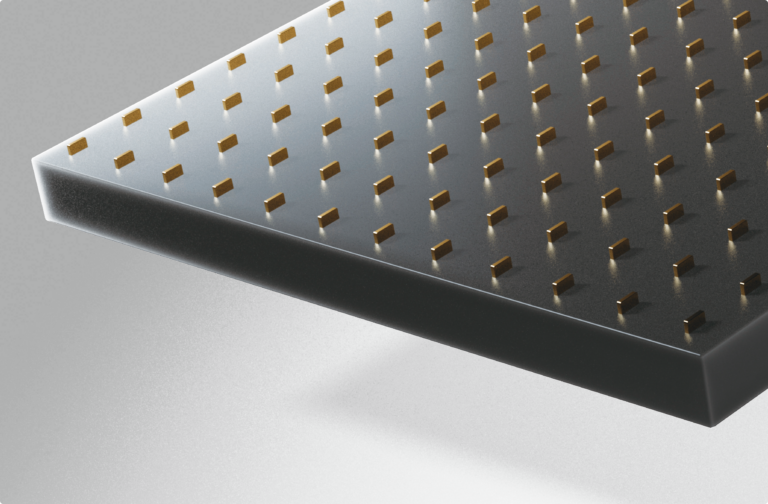

The “MMS” with one-piece construction is suitable for BGA sockets, and minimizes contact failures by reducing the number of components.

In addition, we conducted high-frequency simulation and customized the MMS shape to meet the customer’s required specifications. Therefore, customers further improved measurement accuracy and stability in the millimeter wave band.

Introduction of test sockets : MMS (Micro Metal Socket®)

MMS is an innovative final test socket that responds to the evolution of semiconductor ICs. In anticipation of the 5G and AI era, high-frequency and high-current needs are on the rise, and semiconductor IC final test solutions must respond in the same way. In addition, final test sockets that can adapt to the trend toward more compact and narrower pitch semiconductors are demanded. MMS meets these complex requirements and contributes to the development, design, and manufacturing of next-generation semiconductors.