UPT can manufacture high-quality polyimide heaters with high-precision etching. Copper foil etching for manufacturing heaters requires precision processes and many techniques.

What are Polyimide heaters?

Polyimide heaters are highly flexible, thin electric heaters using polyimide film as the base material.

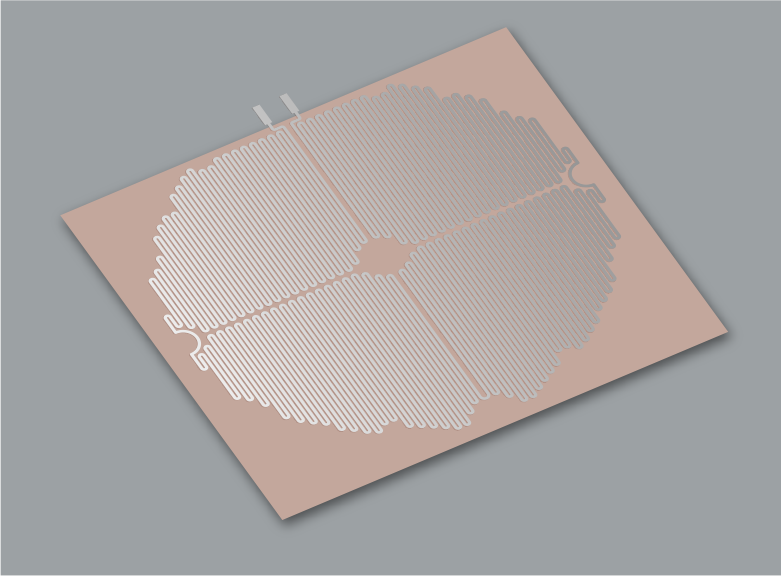

By using polyimide film as the base material and etching copper foil, precise and complex heating patterns can be formed, resulting in efficient and uniform heating performance.

High precision and uniform heating performance are realized despite its thin profile and light weight.

Our polimide heaters can have curved surfaces and complex shapes, and demonstrate stable performance over a wide range of temperatures with excellent heat and chemical resistance.

Manufacturing example: Heaters with etched copper foil on polyimide

The etching process for copper foil requires precision processes and many techniques. First, a pattern is formed on the substrate using photolithography technology. Then, a special etchant is used to remove the unwanted portions to create the wiring. Control of temperature and fluid flow is important in each process and determines the uniformity of the heaters. Finally, unnecessary resist is removed and the quality of the finished product is checked by optical inspection and continuity testing.

Through these processes, high-precision patterning is achieved.

Product Specifications

Material: Polyimide + SUS, Polyimide + Cu

Thickness: Polyimide: 25 μm~

Metal foil: 10 μm~

Processing method: Etching

Leave it to UPT to manufacture polyimide heaters!

UPT uses etching processing technology to achieve advanced techniques to minimize warping and distortion of metallic foil that is controlled to a high quality level.

This technology enables us to produce metal foil heater products with high processing accuracy.

| Specification | Content |

| Material | Stainless, Copper |

| Thickness | 10μm~ |

| Accuracy | Etching accuracy: ±0.02mm~ Negotiable depending on material thickness and pattern |