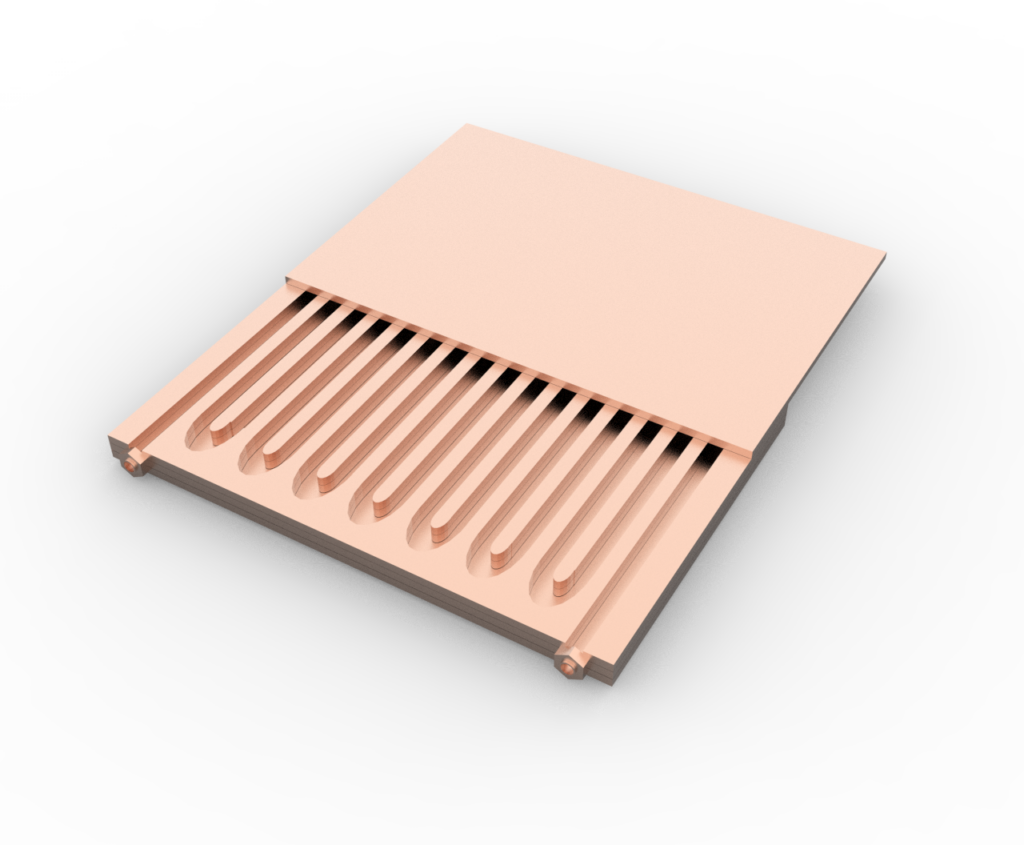

A microchannel heat exchanger features numerous microscale channels that significantly improve heat transfer efficiency while enabling compact, lightweight designs and reduced refrigerant charge compared to conventional heat exchangers. This makes them ideal for a wide range of applications, including HVAC systems, refrigeration, and transportation equipment.

At UPT, we addressed a customer’s challenge of achieving small size, high precision, and wide temperature performance by supporting product design from the simulation phase and proposing a manufacturable solution that met the required specifications. Through collaborative design optimization and advanced processing, we successfully realized a high-performance microchannel heat exchanger.

UPT leverages a combination of photo etching and diffusion bonding technologies, enabling ultra-precision metal processing and complex 3D structures that are difficult to achieve with conventional methods. This unique capability allows us to provide comprehensive support for microchannel heat exchanger design, manufacturing, and assembly with high accuracy and performance.

Case Study: Microchannel Heat Exchanger Manufacturing

The customer was seeking a compact, high-precision microchannel heat exchanger capable of operating under both high- and low-temperature conditions but faced difficulties in finding a suitable manufacturing partner.

In response, UPT supported the design from the simulation stage and proposed a manufacturable heat exchanger solution, leveraging high-precision processing via photo etching and diffusion bonding.

Customer Challenges

The customer required a microchannel heat exchanger to be integrated into a new product but was close to abandoning the project due to problems finding a manufacturing partner capable of meeting the following specifications:

- Compact heat exchanger design

- High heat transfer precision

- High- and low-temperature operational capability

UPT’s Proposal and Solution

Product Design Support from the Simulation Stage

To address the customer’s specific challenges, UPT became involved from the simulation stage and proposed a concrete, manufacturable product design that reliably met the requirements.

Manufacturing Technology Utilizing Photo Etching and Diffusion Bonding

By combining photo etching and diffusion bonding technologies, UPT enabled microscale flow channels and complex 3D structures. Compared with other manufacturing methods, this approach achieves higher heat transfer precision within the same footprint.

One-Stop Procurement and Assembly Support

UPT also handled integrated procurement of piping components and pipe assembly, significantly reducing the customer’s purchasing workload and simplifying the overall assembly process.

UPT’s manufacturing technology

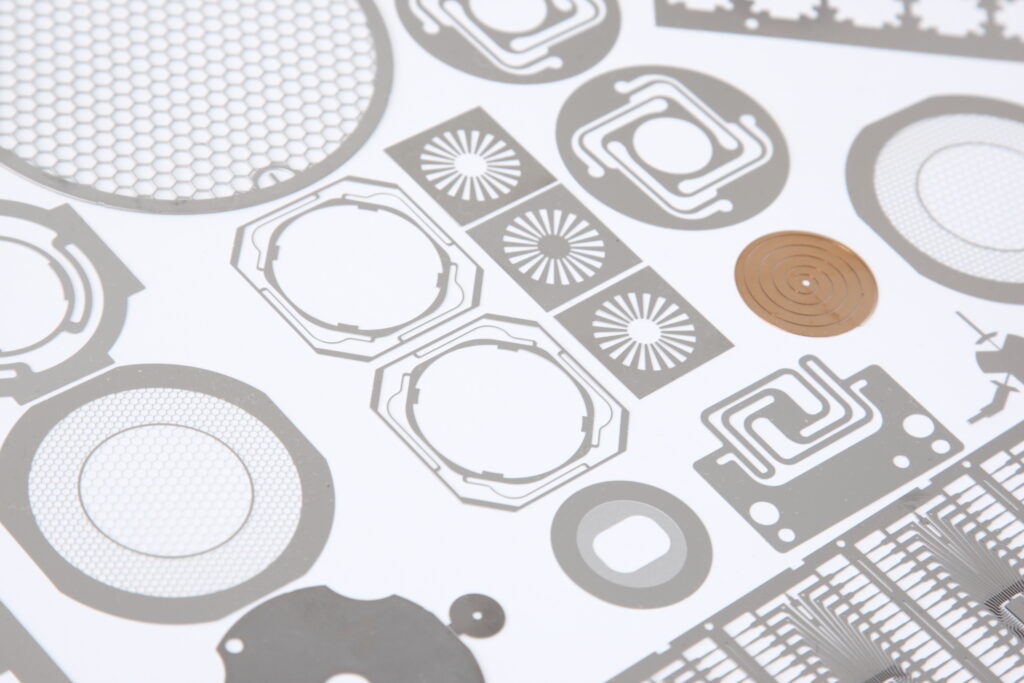

UPT develops and manufactures a variety of products by combining the elemental technologies of photo-etching and diffusion bonding.

Photo Etching Technology

Photo Etching Technology uses an etching solution to chemically react and corrode the metal to allow precise processing of thin metal sheets.

Diffusion Bonding Technology

Diffusion bonding technology allows the molecules to bond to each other on the surface of the metal to create a 3D structured metal part inside.