A microchannel heat sink is a component primarily used for thermal management in electronic equipment and semiconductor devices and is designed to efficiently remove the heat generated during operation. It is typically made from highly thermally conductive materials such as aluminum or copper and contains internal flow channels that allow a coolant to circulate.

By combining its core photoetching technology with diffusion bonding, UPT can fabricate complex microchannel structures inside the heat sink, achieving improved heat dissipation performance.

Key Features of Microchannel Heat Sinks

Microchannel heat sinks are components primarily used for thermal management in electronic equipment and semiconductor devices and are designed to efficiently remove heat generated during operation. They are typically manufactured from highly thermally conductive materials such as aluminum or copper and include internal flow channels that circulate a coolant. This structure enables heat from electronic components to be rapidly transferred to the heat sink and effectively dissipated through the circulating coolant.

Microchannel heat sinks are widely applied in various cooling applications, including computer CPUs and GPUs as well as power electronics equipment. They are especially effective in improving system reliability under high workloads and high heat-generation conditions. Since the shape and dimensions of microchannel heat sinks can be customized depending on the application, they play an important role as an efficient thermal control solution tailored to specific requirements.

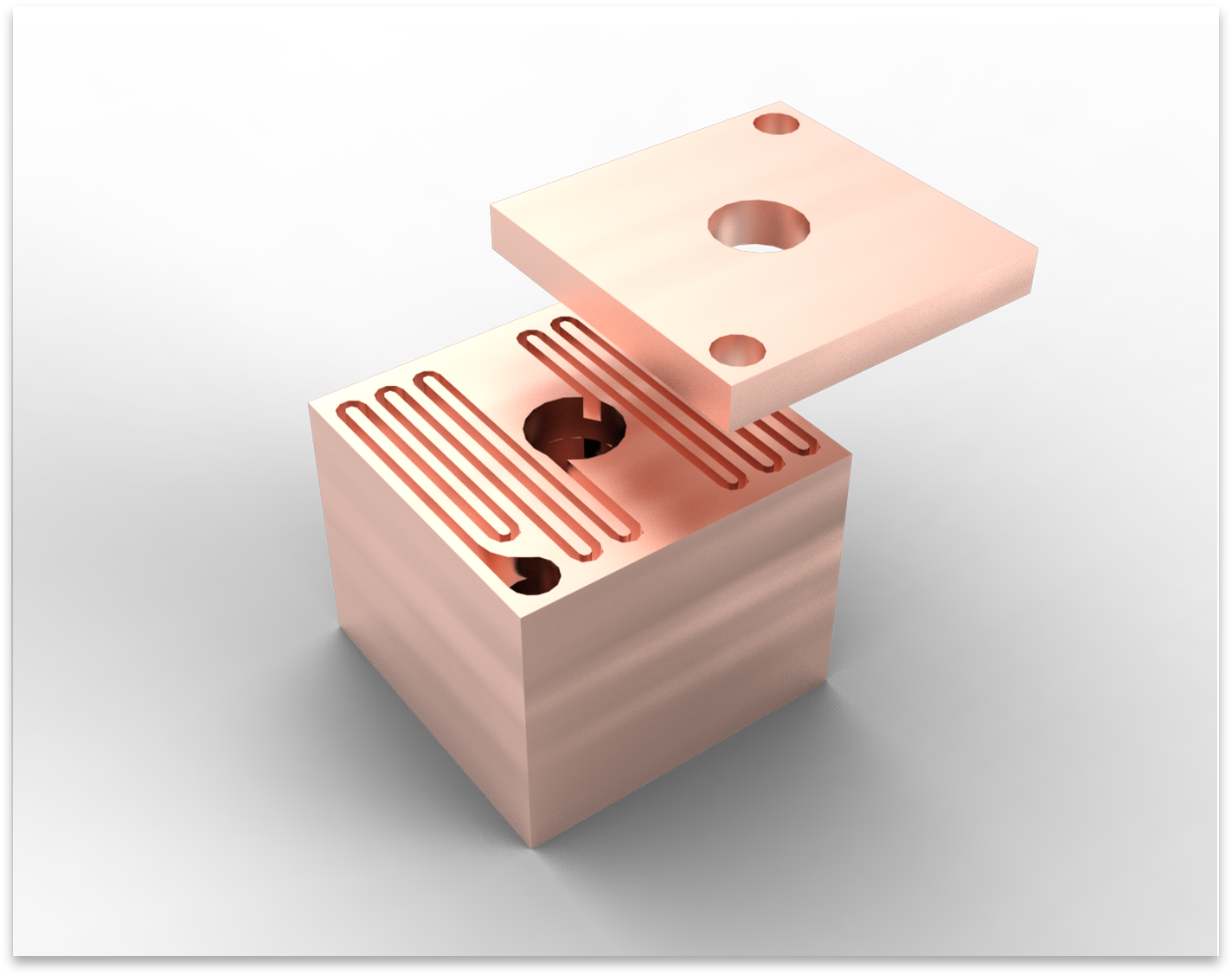

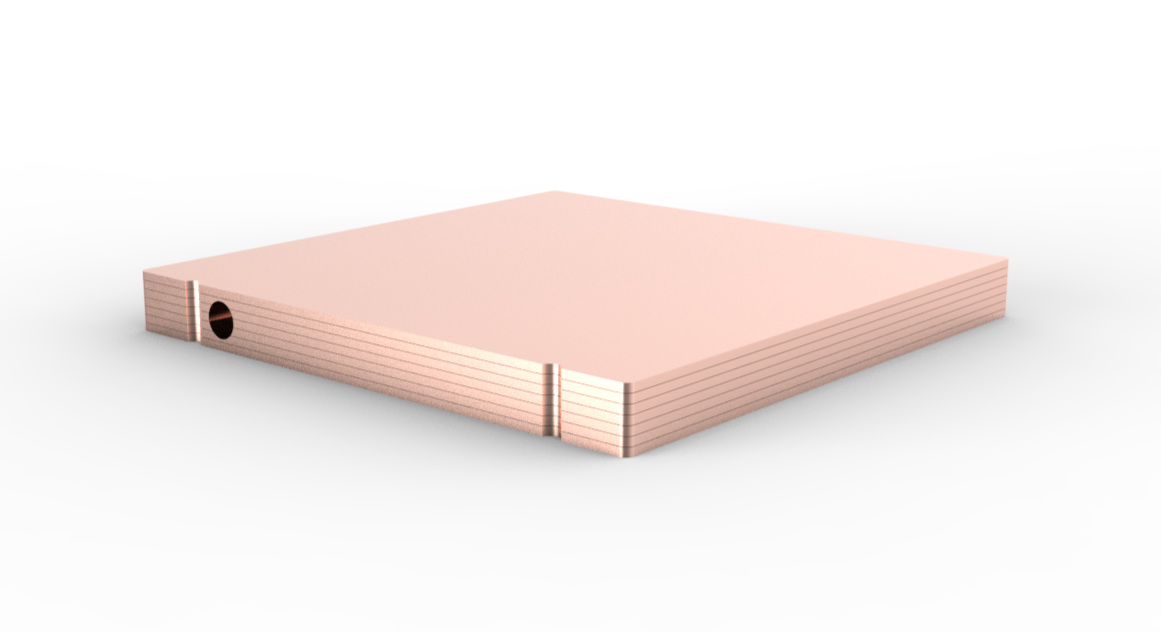

Case Study: Heat Sink for Temperature Cycling Tests

By forming complex microchannels, improved heat dissipation performance can be achieved. In addition, since no tooling is required for flow-channel fabrication, multiple prototype evaluations can be conducted with a short lead time. Combined with thermal simulation, this enables a shorter transition time to mass production.

Material: Copper

Thickness: 0.5 mm/layer

Number of layers: 60 layers (30 mm total thickness)

Channel width: 0.6 mm

Overall dimensions: 30 mm × 30 mm

Manufacturing process: Photoetching + diffusion bonding

UPT’s Thermal Solutions

In addition to heat sinks, we offer a wide range of thermal solutions. We propose the most suitable solution based on each customer’s requirements, so please feel free to contact us for a consultation. Below are some examples of products we have manufactured.

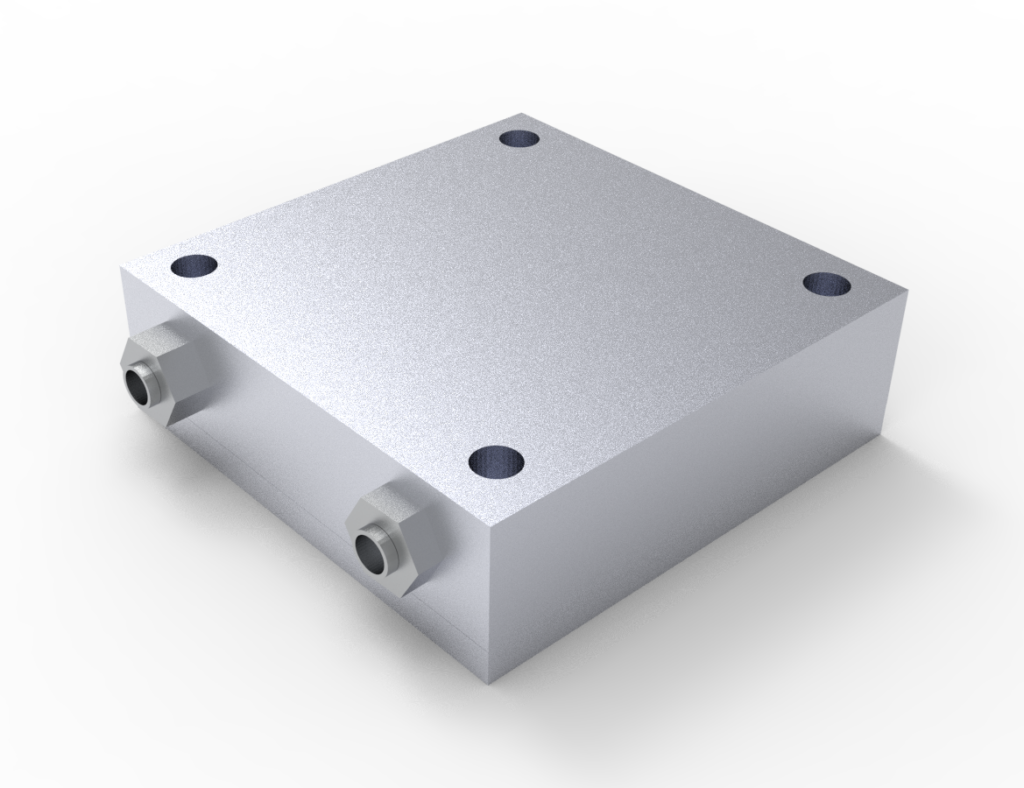

Cold Plate

Cold plates are indispensable cooling solutions for electronic equipment and semiconductor devices. At UPT, we integrate photoetching technology with diffusion bonding to produce cold plates that deliver maximum cooling performance.

Water-Cooled Heat Sink

A water-cooled heat sink is a cooling solution designed to efficiently remove heat from electronic equipment and computer CPUs. By combining photoetching technology with diffusion bonding, UPT can maximize the cooling performance of these components.

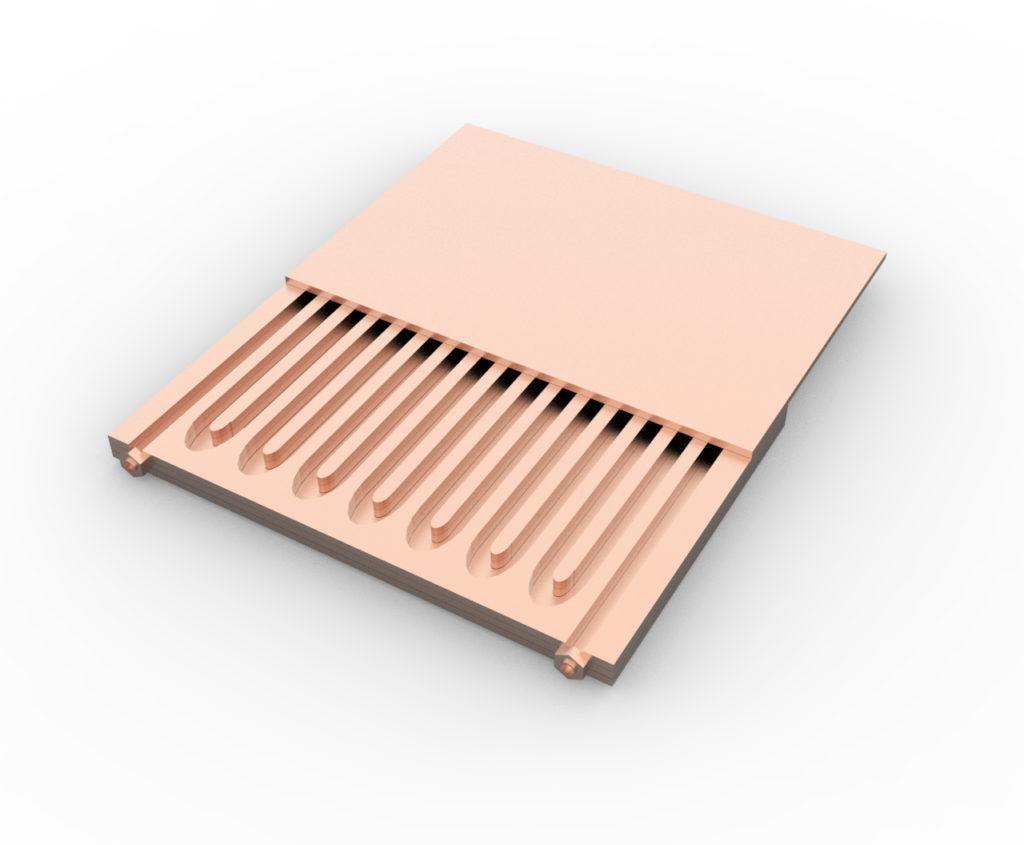

Small (Thin) Heat Sink

UPT manufactures small (thin) heat sinks with microchannel structures using an original production method that combines photoetching and diffusion bonding technologies. Despite their compact and thin design, these heat sinks provide high heat dissipation performance.