UPT can manufacture encoder scales for optical linear encoders. If you are facing issues such as insufficient resolution, unmet delivery deadlines, or cost discrepancies with your current methods, please do not hesitate to contact us for a consultation.

What is Encoder Scale?

An encoder scale is a reference line (a physical line, film, or tape) used in conjunction with a linear encoder, and serves as a reference for the encoder to move. The linear encoder reads position changes on this scale.

Etching plays an important role in the manufacture of linear encoder scales. This process can precisely engrave minute patterns on metal substrates. Linear encoder scales are used in position detection systems to measure the movement of objects with high accuracy. Etching technology makes it possible to manufacture scales with extremely high resolution, which are used especially in the manufacturing processes of semiconductors and precision equipment.

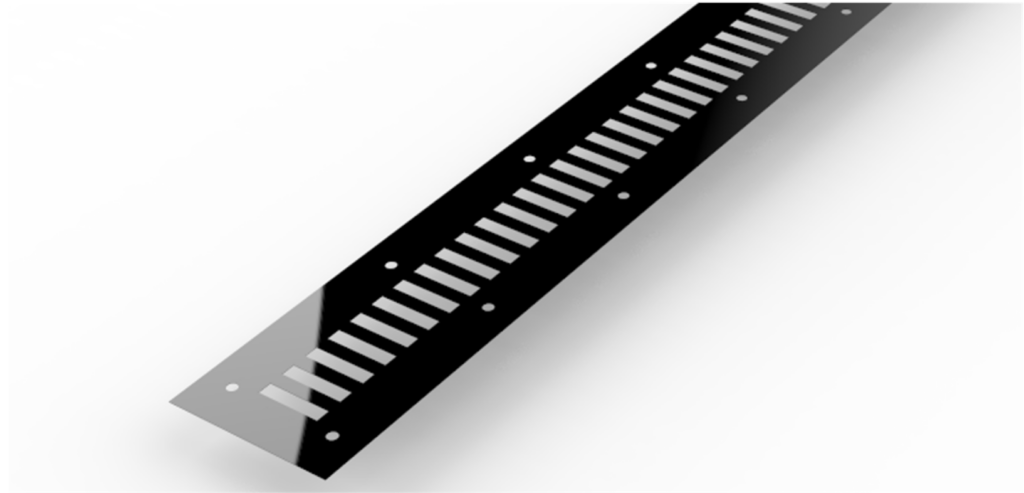

Manufacturing example: Linear encoder scale

Product Specifications

Material: SUS304

Thickness: 0.1mm

Process: Etching

Surface treatment: Black plating

Slit width: 3mm/ 6mm pitch

Size (width x length): 40mm x 370mm

Leave it to UPT to design and manufacture discs and scales for optical rotary encoders!

At UPT, we use etching technology that minimizes warping and distortion of metal foil. Scales produced by this technology are free of burrs, and enable manufacturing products with high dimensional accuracy of ±10% of plate thickness.

| Specification | Content |

| Material | Any etchable metal excluding tungsten, gold and silver |

| Thickness | Available in any thickness from 0.004mm~ |

| Accuracy | ±10% of plate thickness (Minimum tolerance ±0.01mm~) |

| Surface Treatment | Various surface treatments (e.g., black treatment) are available |