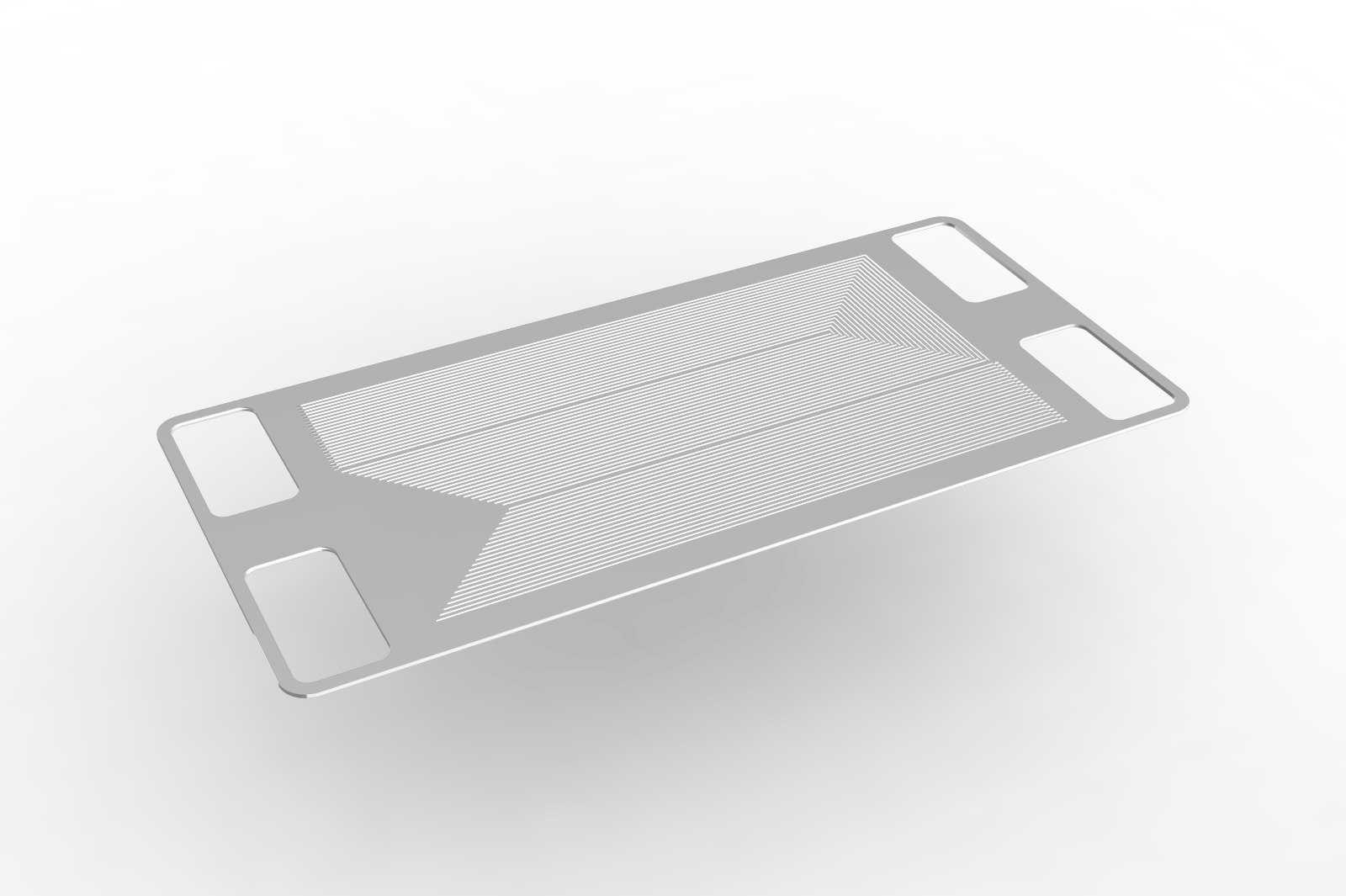

Here is an example of separator production featuring thin-wall molding and high aspect ratio. By combining photo-etching technology and diffusion bonding, UPT have achieved a long service life by processing to an ultra-thin channel width of 0.05 mm and an extremely small channel pitch.

What is a separator?

A separator is a partition or compartmentalizing component used to separate objects or spaces. For example, in a battery, a separator is a membrane or film used to separate electrodes and prevent short circuits. Separators are also used in industrial machinery and manufacturing processes as devices to separate different materials or substances.

Designing separators with extremely small channel widths and channel pitches provides many advantages, such as increased efficiency and miniaturization. Specifically, smaller channel widths and pitches optimize the flow of materials and liquids, and in batteries and fuel cells, improve energy density and heat dissipation efficiency, thereby increasing overall performance. In addition, the more precise the design, the more compact the overall device can be, resulting in advantages such as reduced installation space and weight.

Case Study

Here we present a case study on the manufacture of separators featuring thin-wall molding and high aspect ratio. By combining photo-etching technology and diffusion bonding, UPT have achieved ultra-thin molding of 0.05 mm. In addition, 0.4 mm wide flow channels can be arranged at 1 mm intervals, enabling efficient gas movement. SUS316L, titanium, and aluminum, which have excellent corrosion resistance, are used as materials, and etching and diffusion bonding technologies are used to ensure long service life.

Material: SUS316L

Thickness: 0.4mm

Width of flow channel: 1mm

Flow channel pitch: 2mm

Delivery time: 2 weeks (prototype)

Processing method: Photo etching + diffusion bonding

UPT’s manufacturing technology

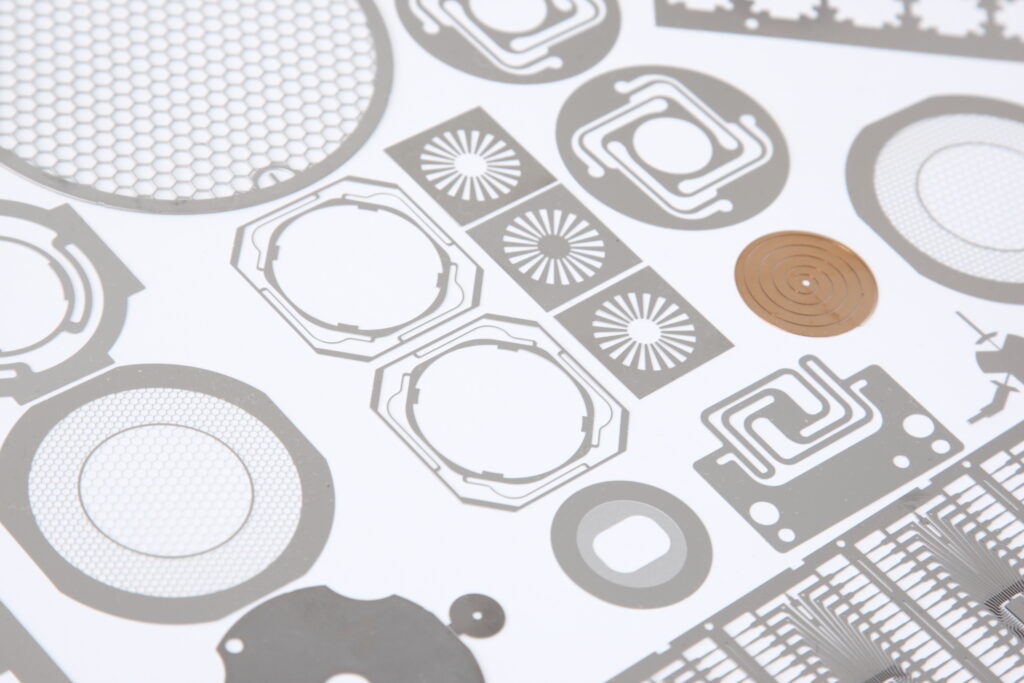

UPT develops and manufactures a variety of products by combining the elemental technologies of photo-etching and diffusion bonding.

Photo Etching Technology

Photo Etching Technology uses an etching solution to chemically react and corrode the metal to allow precise processing of thin metal sheets.

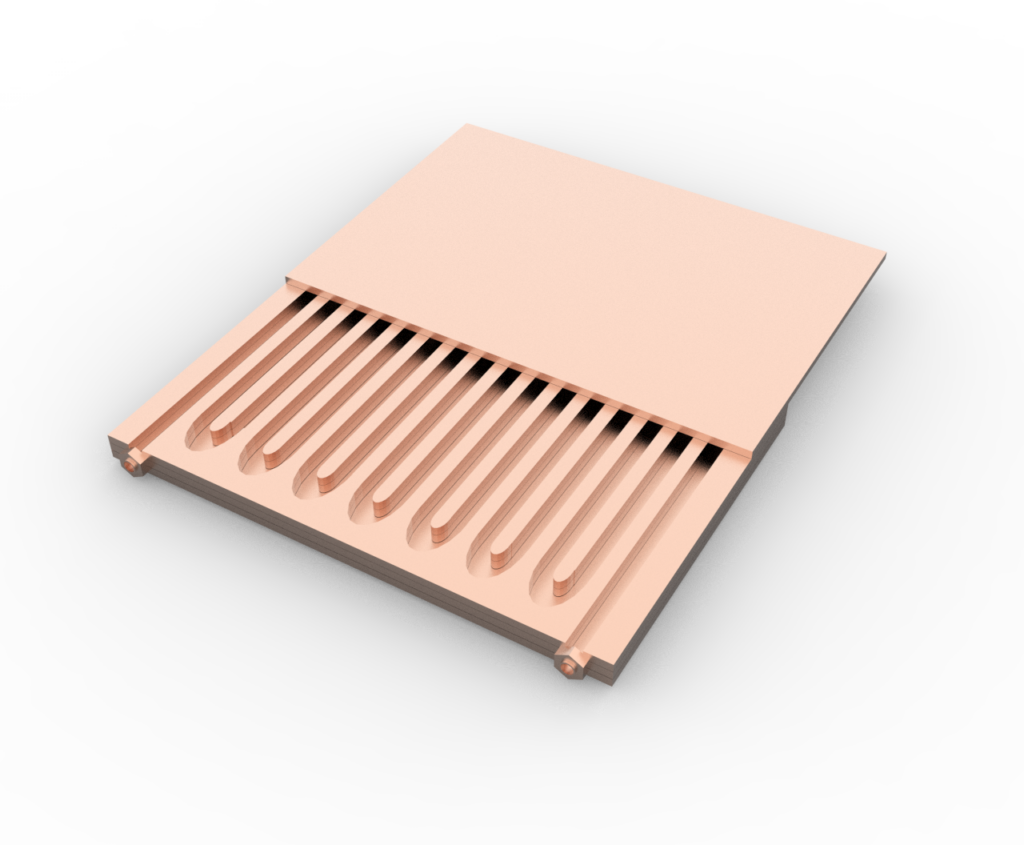

Diffusion Bonding Technology

Diffusion bonding technology allows the molecules to bond to each other on the surface of the metal to create a 3D structured metal part inside.