High-Thermal-Dissipation Liquid Cold Plates With Photo Etching and Diffusion Bonding Technology

Liquid cold plates are essential cooling components for electronic equipment and semiconductor devices. UPT offers high-thermal-dissipation liquid cold plates with photo etching and diffusion bonding technology.

Key Features of UPT’s Liquid Cold Plates

| Flow Path | Fine, with a minimum width of 70 ㎛ |

| Cooling Performance | Over 2 kW with a small amount of coolant |

| Thickness | Compact size, with 3 mm thickness |

| Airtightness | High atomic-level bonding strength |

| Design | Custom flow path design and simulation |

| Lead Time | Short (no mold required) |

What are Cold Plates?

Liquid cold plates are essential components for thermal management in electronic and semiconductor devices. Made from materials with high conductivity such as copper or stainless steel, they feature internal channels that allow coolant to flow and efficiently dissipate heat. By maintaining optimal operating temperatures, they improve performance stability and extend device lifespan. These plates are widely used in high-performance computers, servers, semiconductor equipment, and medical devices requiring high cooling capacity.

| Air Cooling(Heat Sink) | Liquid Cooling(Cold Plate) | |

|---|---|---|

| Cooling Mechanism | Fan-forced convection | Heat transport via liquid circulation |

| Cooling Performance | Low–mid | Mid–high |

| Introduction Cost | Low | Mid–high |

| Running Cost | High | Low–mid |

| Electrical Power for Cooling | Large | Small |

| Temperature Control Accuracy | Low | High |

UPT’s Core Technologies Used in Liquid Cold Plates

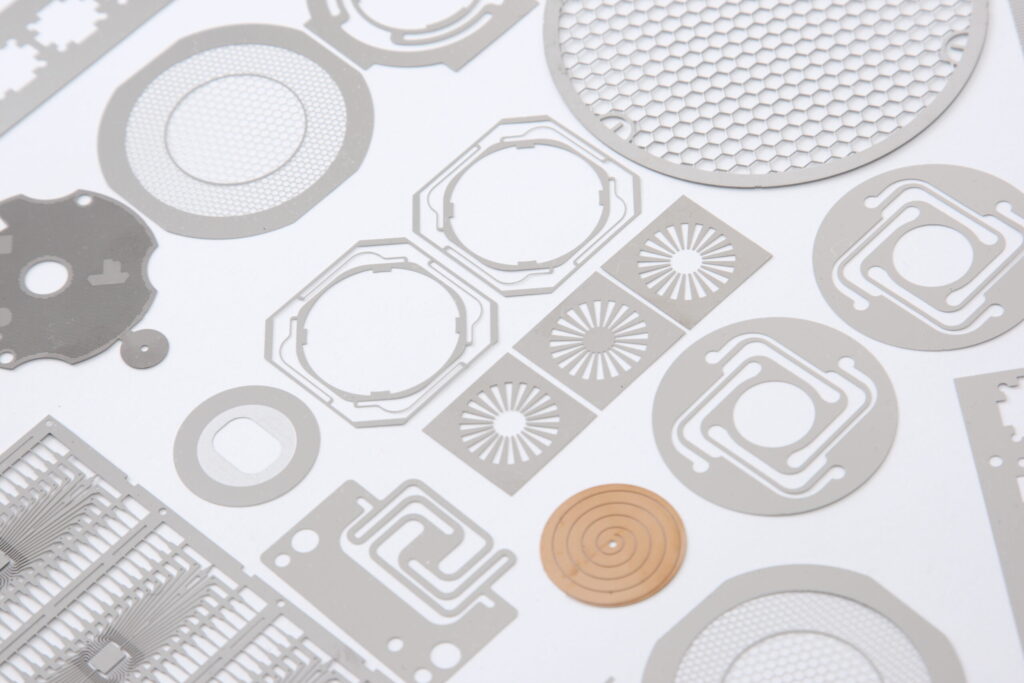

UPT combines photo etching and diffusion bonding technology to manufacture cold plates. This combination offers superior heat dissipation and design flexibility compared with other methods.

Photo etching is the process of using corrosive chemicals to melt specific areas on a metal sheet, resulting in precise, unique and intricate metal parts. This allows for the formation of complex channel structures, enhancing the thermal dissipation efficiency of the coolant.

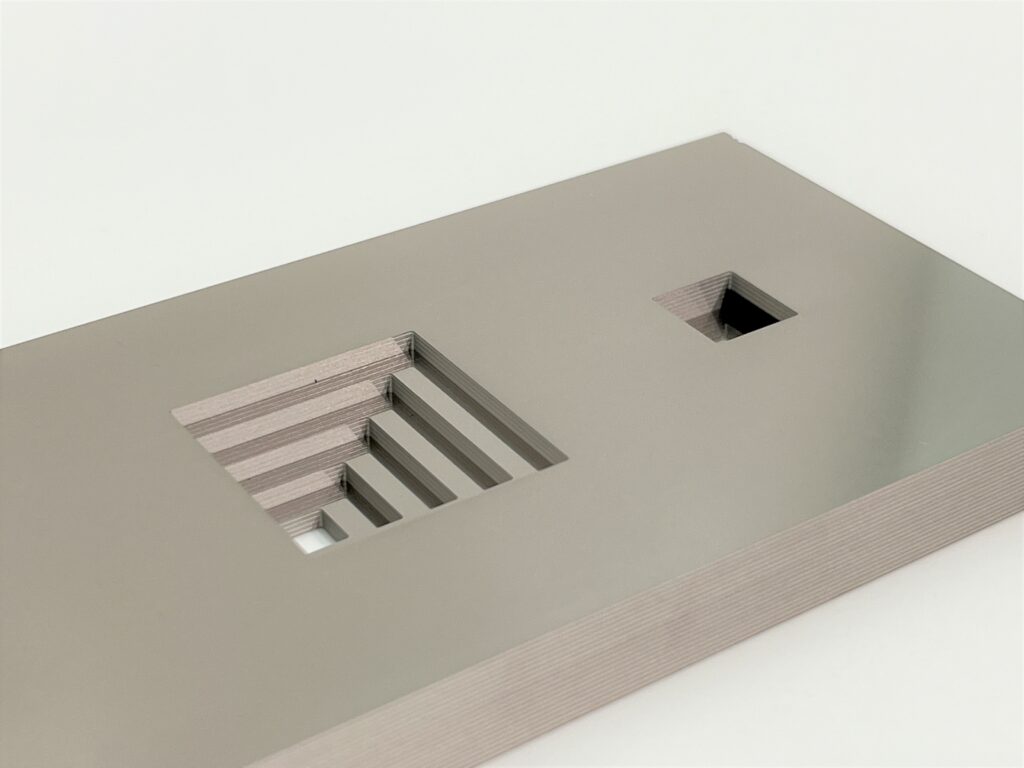

Diffusion bonding is a bonding technique that joins metals at the atomic level by bringing their surfaces close together. It allows for the highly precise creation of metal parts with complex 3D internal structures. Adhesives and spot welding are also commonly used to bond metals, but these techniques have drawbacks such as cleaning difficulties, peeling at high temperatures, and leaving gaps. The combination of photo etching and diffusion bonding technology produces high cooling performance.

Use-Cases of Cold Plates

UPT has solved thermal issues in various fields of electronic equipment. Here are some examples:

Use-Case 1: Cooling Plates for Semiconductors Test Handlers

Customer’s Challenge: Previous cooling plates had insufficient thermal dissipation performance and inconsistent cooling performance among products.

UPT’s Proposal: UPT not only provided products in accordance with the customer’s designs but also proposed solution to shorten heat dissipation time. We designed the optimal channel width based on our simulations to maximize thermal conductivity. As a result, the thermal dissipation amounts improved, contributing to test efficiency and improving productivity. Test yield also improved.

Use Case 2: Cold Plates for Light Source Equipment

Customer’s Challenge: The customer needed higher cooling capability because heat distortion in the exposure lens was reducing laser accuracy. The cooling performance of the existing single flow path design was insufficient.

UPT’s Proposal: UPT’s engineers collaborated with the customer to design a multi-flow-path cold plate that enhanced cooling efficiency and maintained lens precision. This optimized structure effectively dissipated heat, improving laser performance and operational stability.

Specification:

・Material: SUS430

・Processing Methods: Photo Etching + Diffusion Bonding + Machining

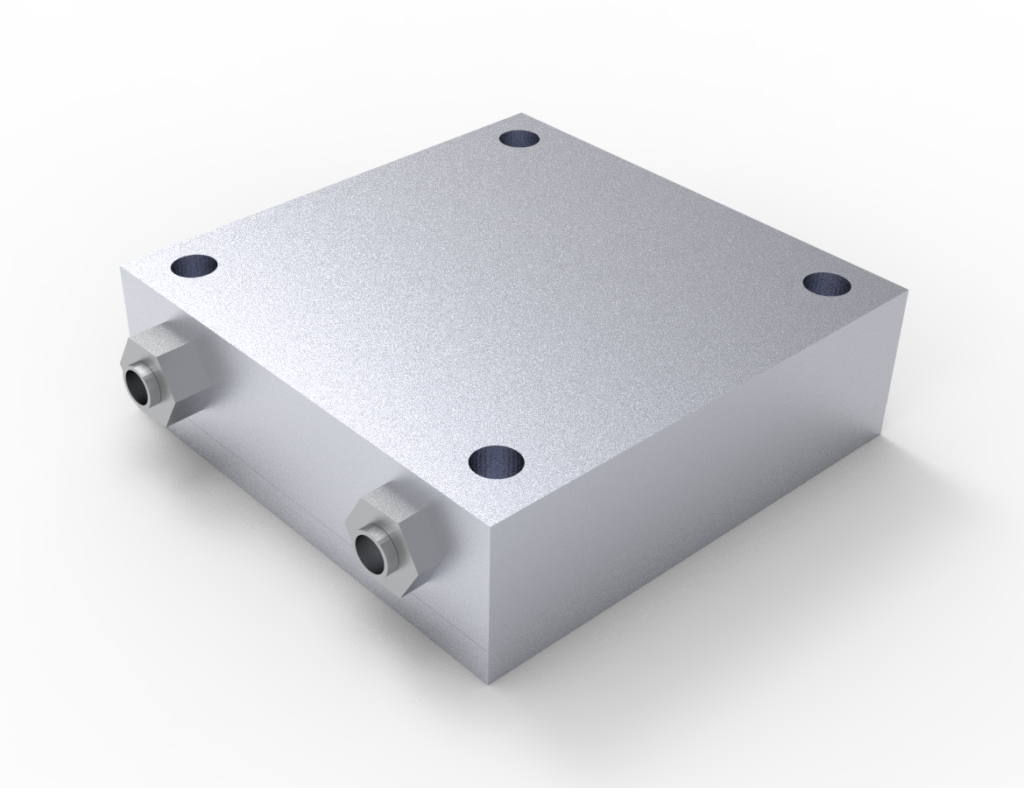

Use Case 3: Cold Plates for Supercomputers

Customer’s Challenge: As power consumption increased, the size and weight of cold plates also grew, leading to higher installation and maintenance costs for the supercomputer system.

UPT’s Proposal: After learning about UPT’s diffusion bonding technology at an exhibition, the customer believed it could enable the production of smaller and lighter cold plates. UPT proposed a compact design using photo etching and diffusion bonding to achieve both high thermal performance and reduced weight, lowering overall system costs.

Specification:

・Material: C1020

・Processing Methods: Photo Etching + Diffusion Bonding

FAQ

-

What information should we share when requesting a quotation for a cold plate?

-

To provide an accurate quotation, please share the following key details: plate size (L×W×H), material (copper, aluminum, stainless steel, etc.), required cooling performance (heat removal in W), and coolant type.

-

What materials can UPT provide for cold plates?

-

We offer copper (C1020), aluminum, stainless steel (SUS series), and other materials upon request. The choice of material depends on thermal conductivity, corrosion resistance, and cost requirements.

-

Can UPT tailor the internal flow path and coolant direction?

-

Yes. You can specify the coolant IN/OUT positions, flow direction, and flow rate, and UPT’s engineers will optimize the flow path design through simulation to achieve the required cooling performance and minimize pressure loss.

-

How much can cooling performance be improved?

-

Cooling performance depends on factors such as heat source temperature, contact area, and coolant conditions. In general, UPT’s cold plates can achieve heat removal of over 2 kW with a compact 3 mm–thick design.

-

What coolant types are compatible?

-

Water, glycol-based fluids, and other custom coolants can be used. We can also support evaluations for special liquids depending on the application.

-

What is the typical lead time for custom cold plates?

-

Since no mold is required, we can offer short delivery times depending on the complexity of the design and material availability. Please contact us for a detailed schedule.

Custom Cold Plates Design

UPT offers custom-designed cold plates. Please contact us if you are facing challenges such as insufficient cooling capacity or limited design flexibility with existing methods.