High Thermal Dissipation Liquid Cooling Plates with Photo Etching and Diffusion Bonding Technology

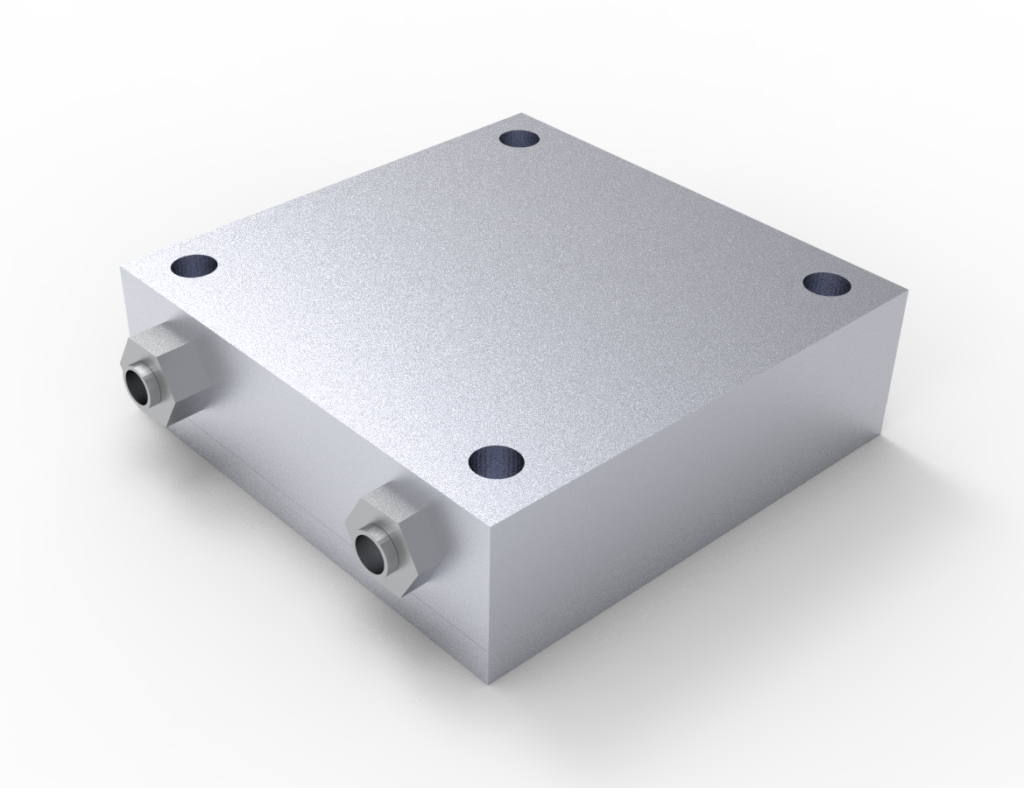

Liquid cooling plates are essential cooling components for electronic equipment and semiconductor devices. UPT offers high thermal dissipation liquid cooling plates with photo etching and diffusion bonding technology.

What are Cooling Plates?

Liquid cooling plates are cooling components used for thermal management in electronic equipment and semiconductor devices. They are typically made of high thermal conductivity materials like aluminum or copper, with channels designed for coolant liquid or air to flow through. This coolant liquid or air efficiently transfers heat generated by electronic devices to the outside, helping to maintain optimal temperatures, enhance performance stability, and enable the devices to run long lifespan. Cooling plates are widely used in high-performance computers, servers, semiconductor manufacturing equipment, and medical devices, where high cooling capacity is required.

UPT’s Core Technologies Used in Liquid Cooling Plates

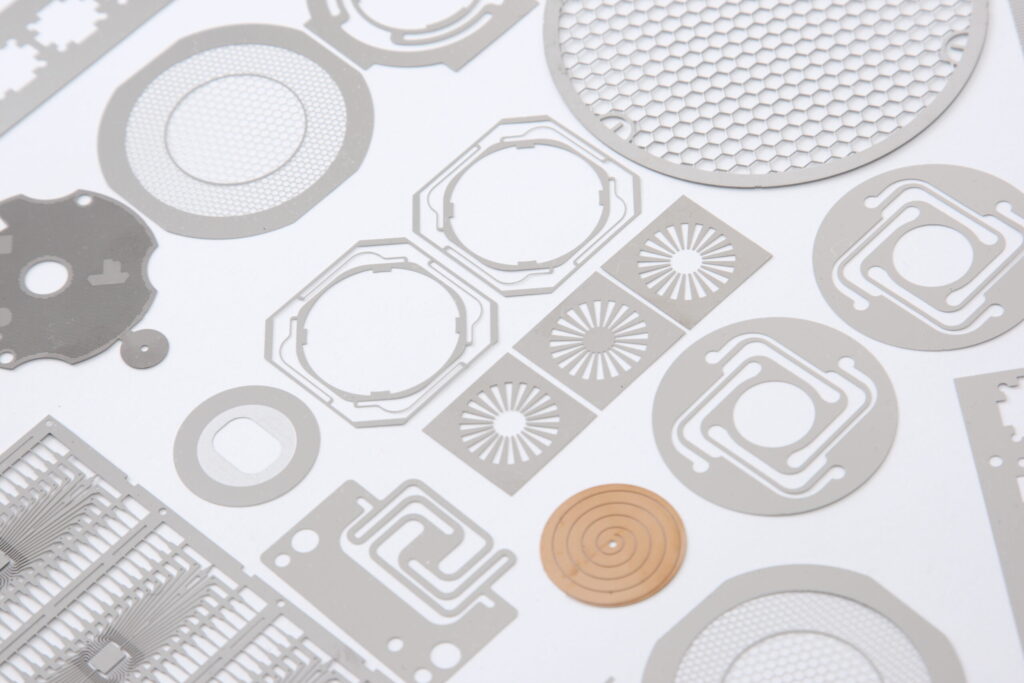

UPT combines photo etching and diffusion bonding technology to manufacture cooling plates. This combination offers superior heat dissipation and design flexibility compared with other methods.

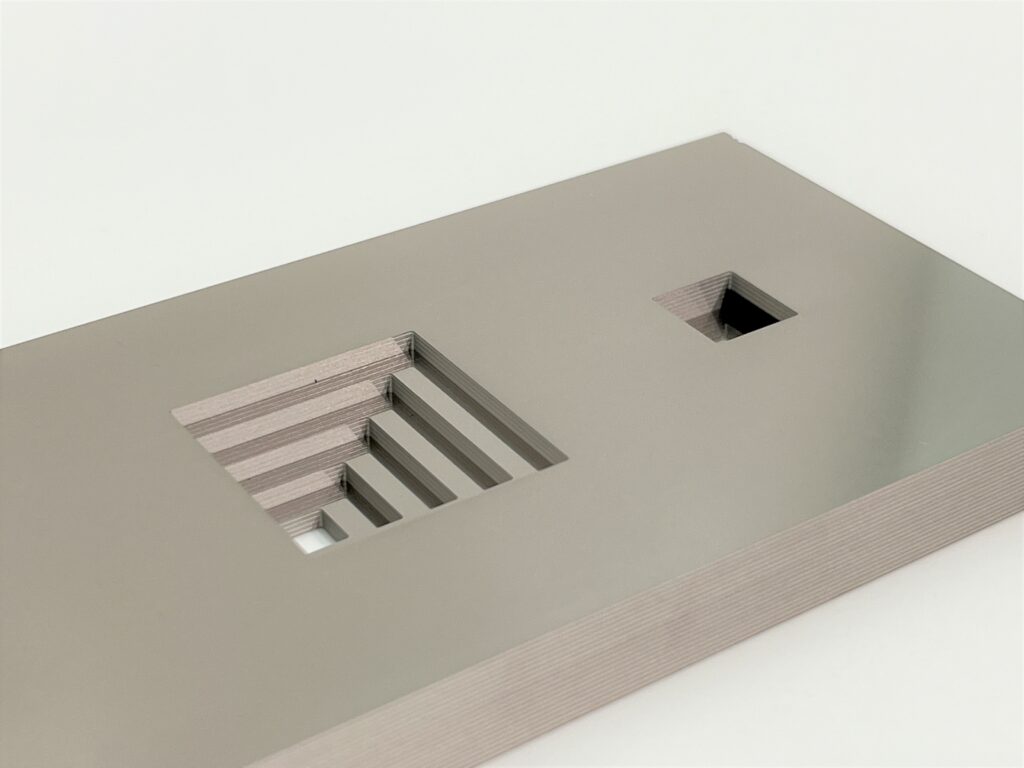

Photo etching technology: Photo etching technology is the process of using corrosive chemicals liquid to melt the specific areas on a metal sheet, and forms precise, unique and complex metal parts. This allows for the formation of complex channel structures, enhancing the thermal dissipation efficiency with the coolant.

Diffusion bonding technology: Diffusion bonding technology is one of bonding techniques that joints metals at atomic level by bringing their surface close together. This technique allows for creation of metal parts with complex 3D internal structures with high precision. Adhesives and spot welding are also used to bond metals commonly, but they have drawbacks such as peeling at high temperature, difficulty in cleaning, and creating gaps. The combination of photo etching and diffusion bonding technology make high cooling performance cooling plates.

Use-Cases of Cooling Plates

UPT has solved thermal issues in various fields of electronic equipment. Here are some examples:

Use-Case 1: Cooling Plates for Semiconductors Test Handlers

Customer’s Challenge: Previous cooling plates had insufficient thermal dissipation performance and inconsistent cooling performance among products.

UPT’s Proposal: UPT not only provided products in accordance with the customer’s designs but also proposed solution to shorten heat dissipation time. We designed the optimal channel width based on our simulations to maximize thermal conductivity. As a result, the thermal dissipation amounts improved, contributing to test efficiency and improving productivity. Test yield also improved.

Use-Case 2: Cooling Plates for Servers

Customer’s Challenge: Air-cooled fins caused overheating problems.

UPT’s Proposal: Compact liquid-cooled cooling plates with high thermal dissipation.

Custom Cooling Plates Design

UPT offers custom design of cooling plates. Please contact us if you are facing challenges such as insufficient cooling capacity or limited design flexibility with existing methods.