Optimize Semiconductor Test and Boost Electronic Device Performance with Flexible Design and High-Speed Signal Properties

What is UHSS® Anisotropic Conductive Film?

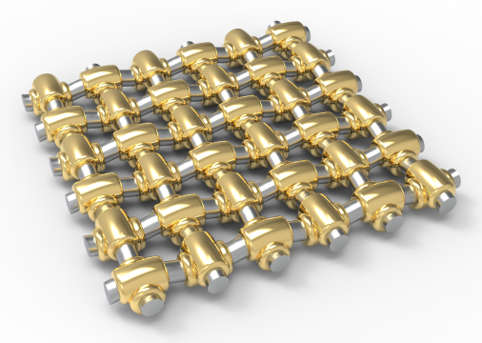

UHSS® is an advanced anisotropic conductive film that combines woven special fibers with plating penetrated both sides. Key features of UHSS® include flexibility maintaining conductivity even when bent, highly customizable design, and high-speed signal properties supporting up to 100 GHz or 200 Gbps. It requires a low contact force load of 1 N/mm² and long durability up to 50,000 times touchdowns. (according to our internal data).

Conductive materials: Copper, Nickel, Gold

Insulating material: High-performance plastic fibers

Key Features

- Dual-sided conductive contact sheet with just 0.05mm thick

- Can be bent up to 180°

- Narrow-pitch, ultra-small contact points (pitch: 0.08mm+, contact points: 0.06mm+)

Performance

- Rated current: 3A per dot (per contact point)

- Transmission speed: 200 Gbps @ -1dB

- Durability: 50,000 touchdowns

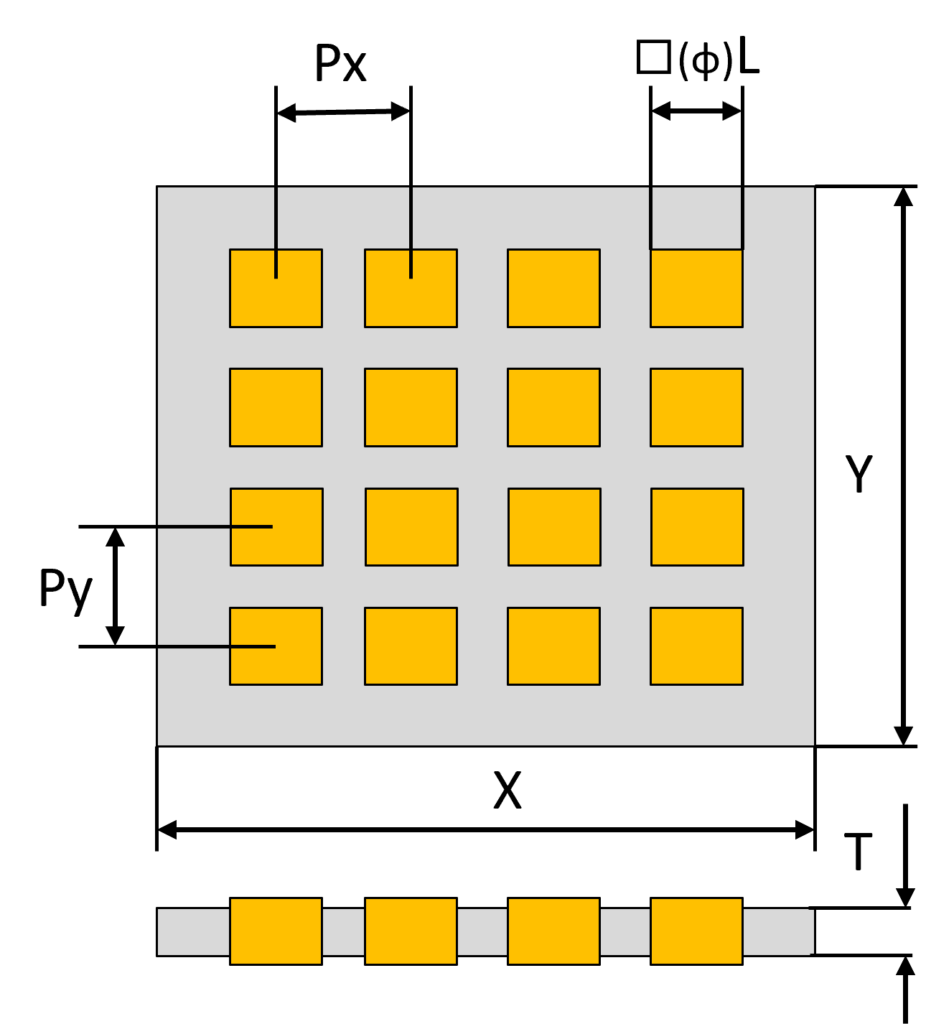

| Pitch (Px) | 0.08mm~ |

| Pitch (Py) | 0.08mm~ |

| Thickness (T) | 0.05mm~ |

| Electrode size (L) | □0.06mm~ |

| Product size (X) | 5.00mm~ |

| Product size (Y) | 5.00mm~ |

Advantages of UHSS®

Flexible Design

Simply placing the sheet between conductive components allows for easy conductivity. Forming custom patterns on the sheet, you can use UHSS® as an excellent alternative to flexible printed circuits (FPC) for creating flexible wiring patterns.

Space-Saving

At just 0.05mm thick, UHSS® can be installed in extremely tight spaces, ideal for applications where space is at a premium.

Long Durability

UHSS® supports 50,000 touchdowns with stable resistance.

High Speed Capability

Despite its thinness, UHSS® supports high speed up to 200 Gbps.

Low Contact force

Low force requirement (just 1 N per 1mm²*) reduces strain on equipment and enables safer designs.

*For a contact stroke of 0.01 mm

Narrow Pitch

Min pitch is 0.08mm.

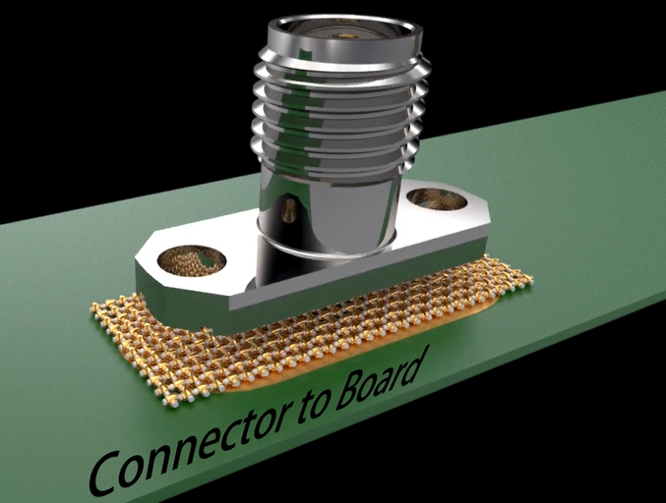

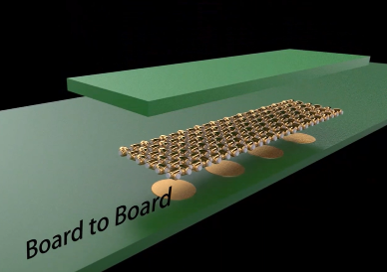

Examples of UHSS® Applications

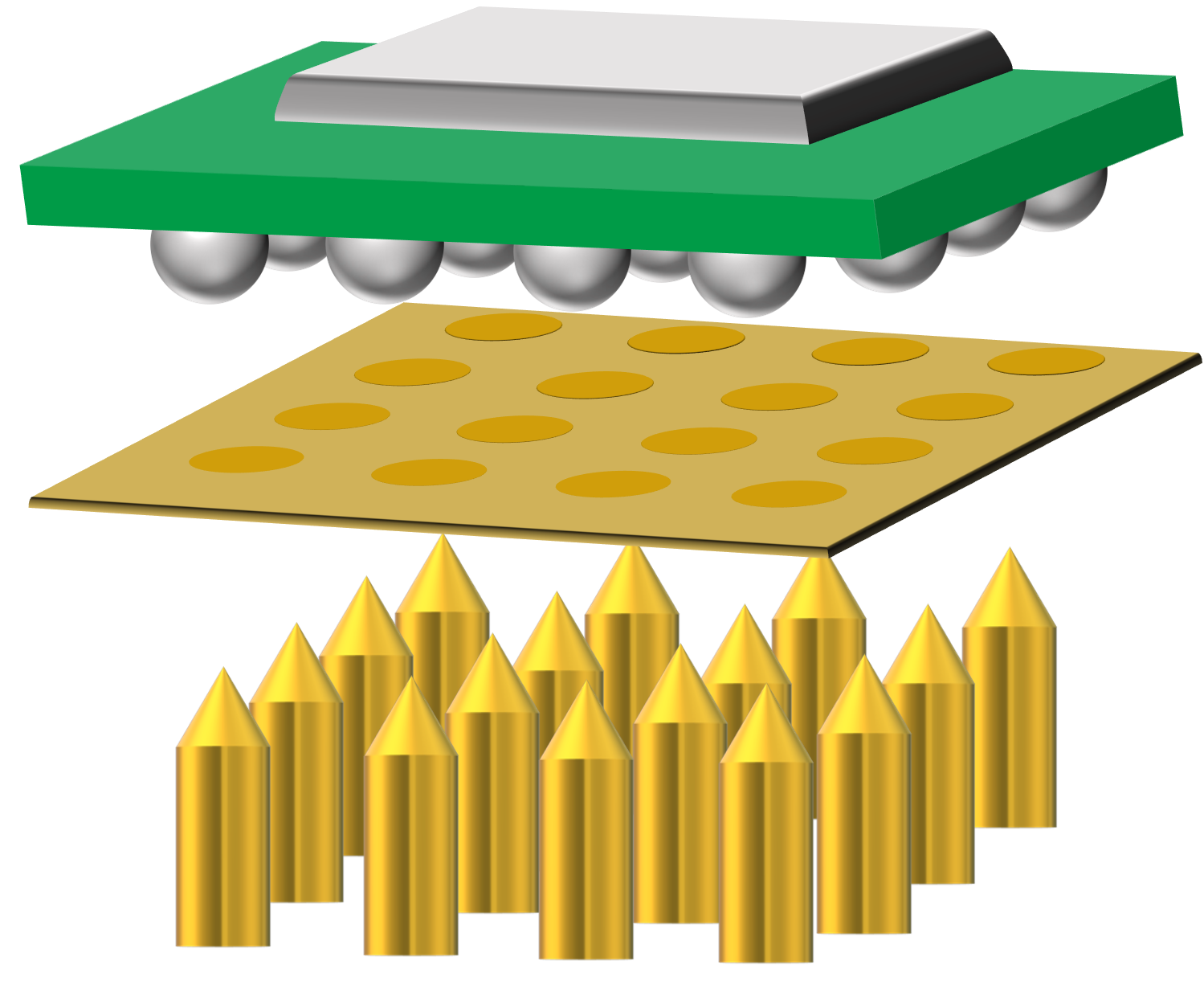

BGA Ball Saver

UHSS® prevents damage to BGA solder balls from the high load of traditional probe pins. It is more flexible than conventional wires and probe pins and can be bent to maintain continuity. It can be used on curved surfaces and in tight spaces, enabling high-density connections to very small devices and pads. Uniform contact pressure improves connection reliability and is suitable for high-speed signal transmission.

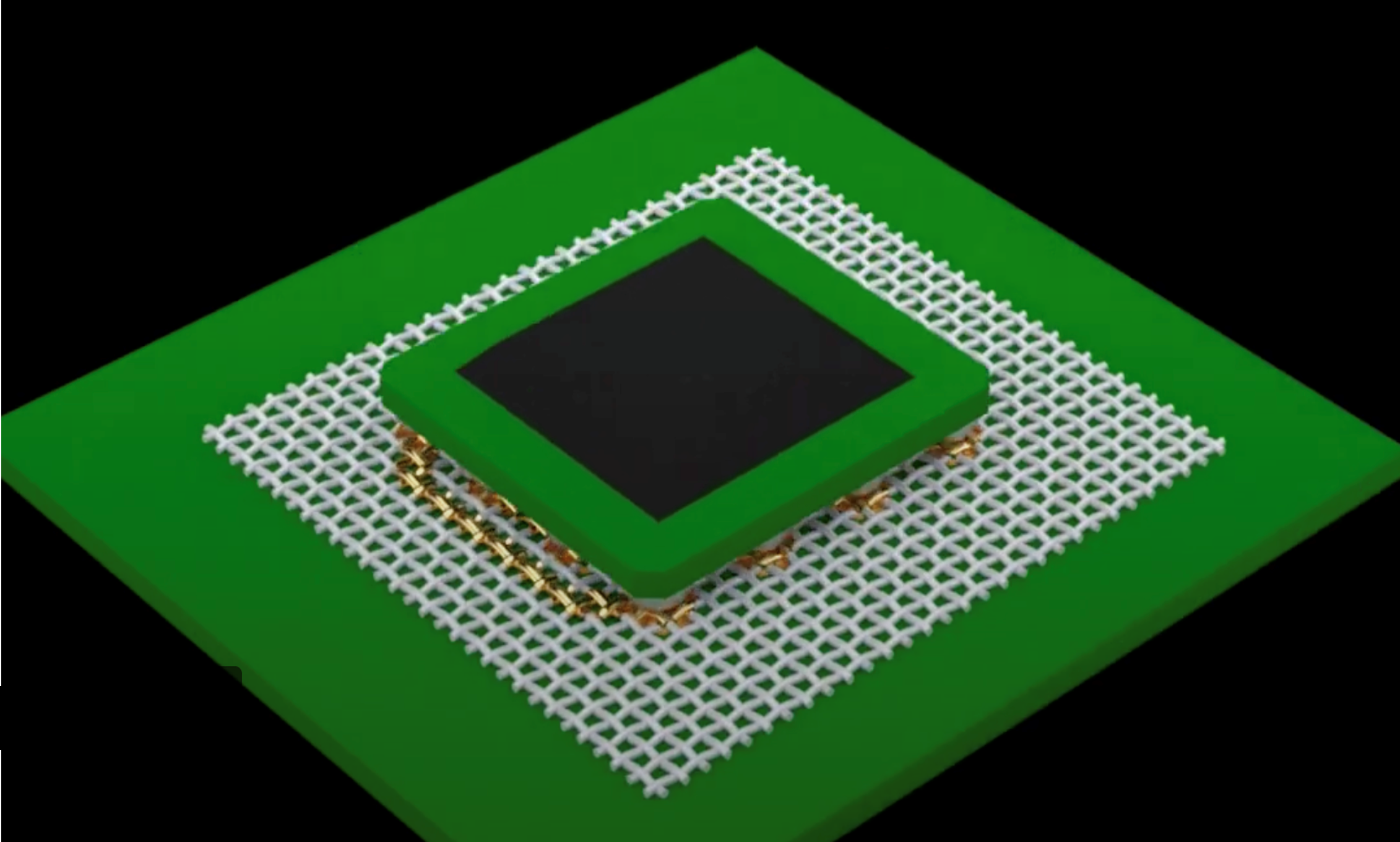

PCB Pad Saver

UHSS® is also available as a PCB pad saver and functions as an electrical connection between electronic components and as a relay board to achieve high-density wiring. It supports high-speed signal transmission and improves connection reliability with uniform contact pressure. This contributes to the construction of high-performance 3D ICs and system-in-packages, greatly improves the quality and performance of electronic devices.

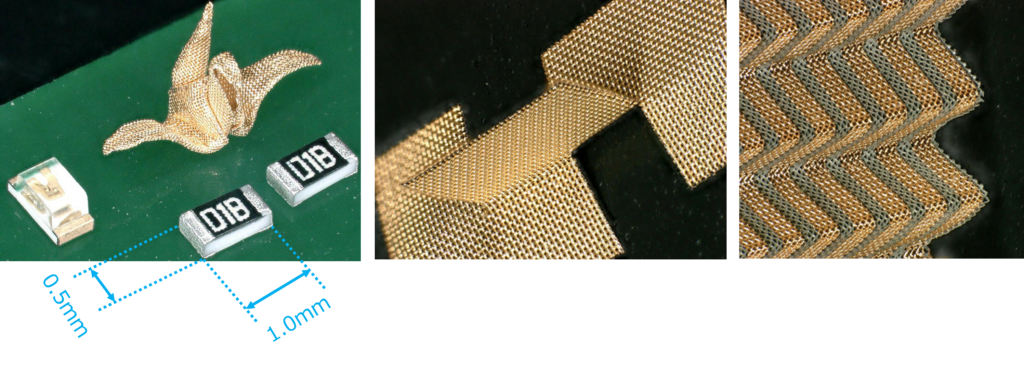

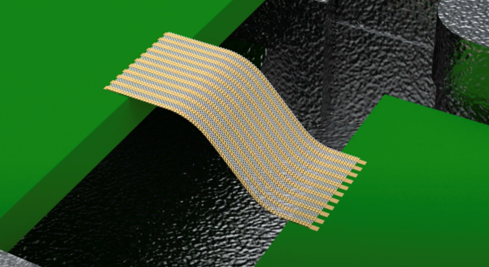

Replace of Flexible Printed Circuit

UHSS® is made of special woven fibers and plated through both sides, allowing free patterns to be formed on the sheet.

This property allows it to be used as an alternative to flexible printed circuit boards (FPC). It has high flexibility and reliability, and can be used in tight spaces and complex shapes. This overcomes the challenges of FPCs and contributes to higher performance and miniaturization of electronic devices.

Bypass Cable

UHSS® can be used as a bypass cable due to its high flexibility and reliability. This is made of special braided fibers and plated through on both sides to support high-speed signal transmission.

Lighter and thinner than conventional cables, it can be adapted to tight spaces and complex shapes. It also has excellent signal transmission stability and durability, and is expected to be used as a bypass cable in various electronic devices and communication systems.

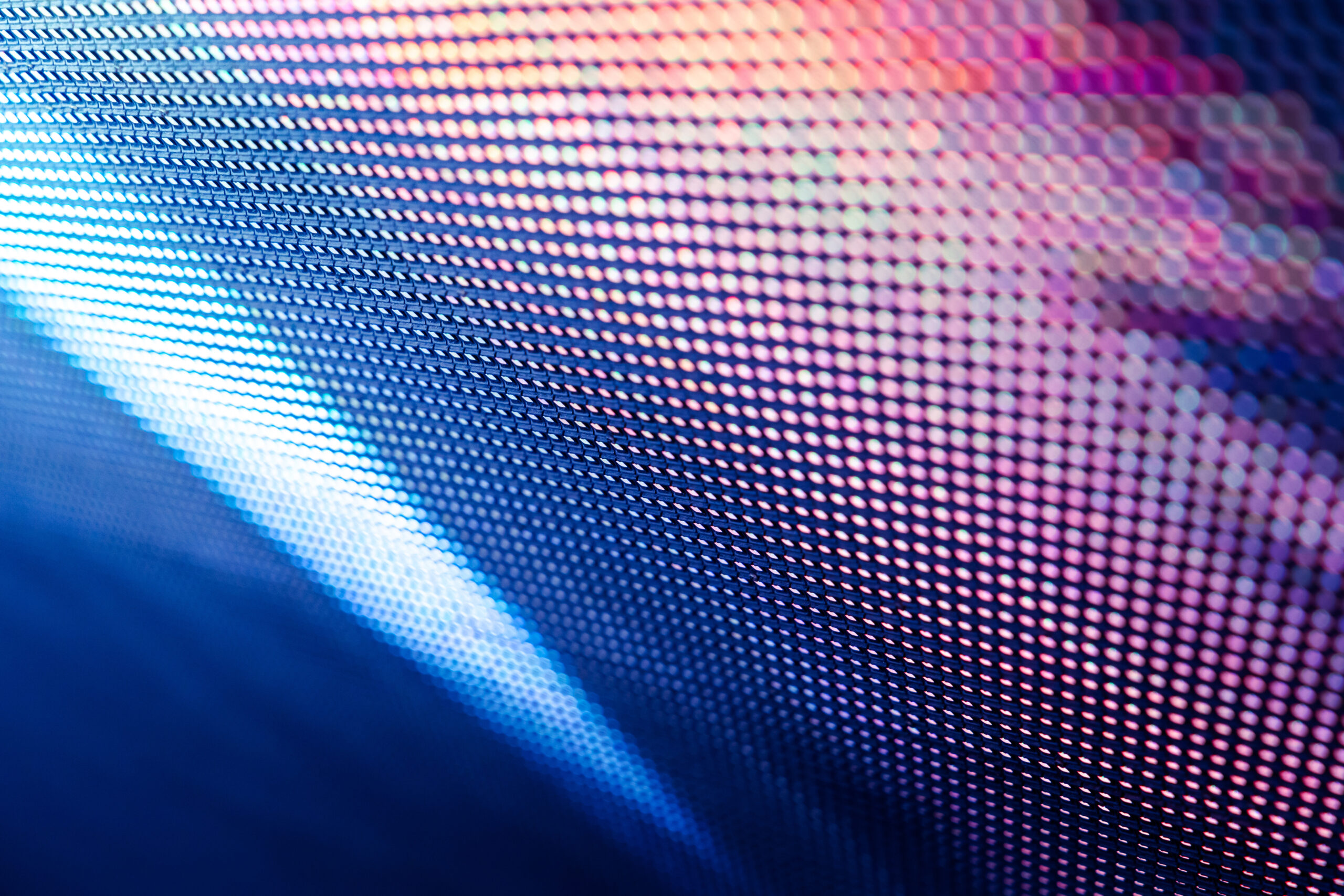

OLED / LCD Display

UHSS® is also ideal for OLED mounting. It supports high-speed signal transmission, provides a reliable connection with uniform contact pressure, and can accommodate narrow spaces and curved surfaces.

It’s excellent thermal conductivity effectively manages the heat generated by OLEDs, contributing to a longer service life. This contributes to higher performance and greater design flexibility for OLED lighting and LCDs.

Use-Cases of UHSS®

Use-Case1

BGA Ball Saver for Test Probe Pins

Customer’s Challenge:

Traditional probe pins used in semiconductor final test caused damage to BGA solder balls due to high contact force.

UPT’s Solution:

Placing UHSS® between the test probe pins and the BGA solder balls ensured stable contact and extended the lifespan of the socket.

Use-Case2

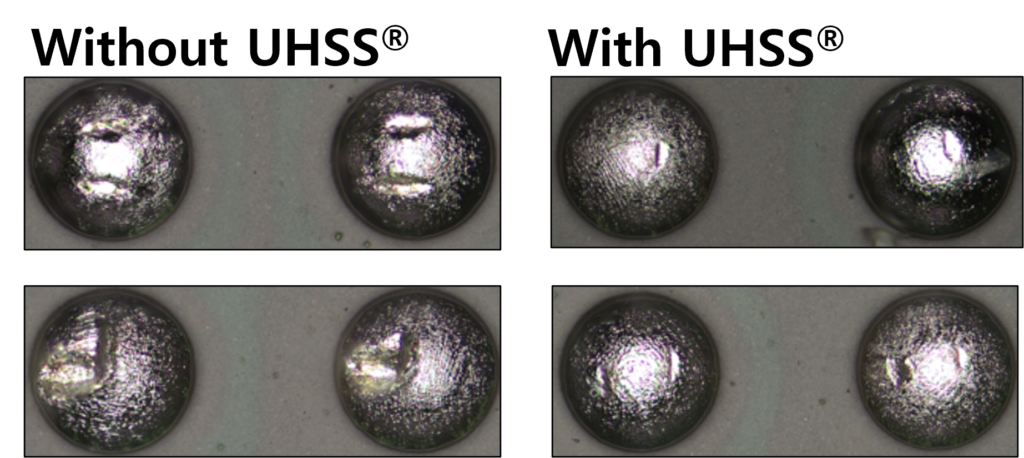

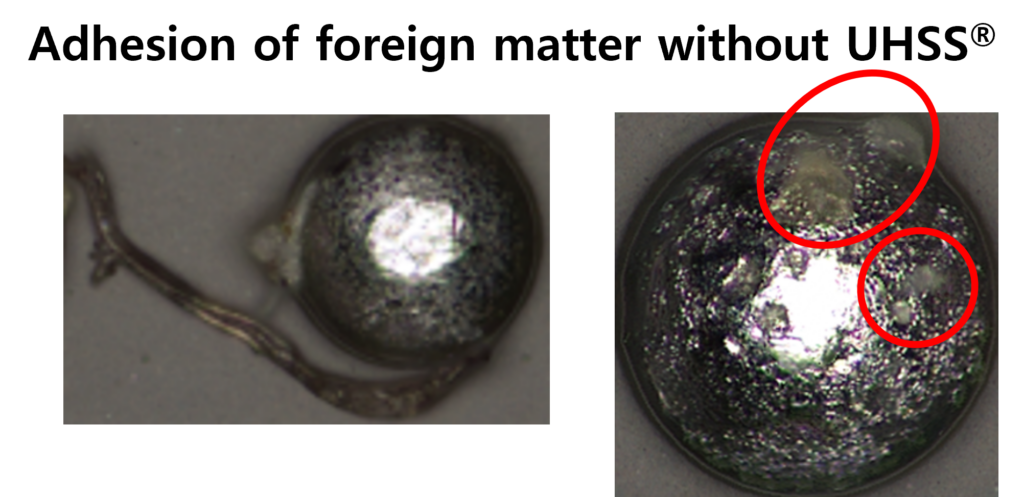

BGA Ball Saver (Silicone Rubber Sockets)

Customer’s Challenge:

In semiconductor IC final test, silicone rubber sockets caused contamination, with foreign materials like silicone adhering to the BGA solder balls.

UPT’s Solution:

Placing UHSS® between the silicone rubber socket and the BGA solder balls, ensured stable contact and eliminated the contamination issue.

Use-Case3

PCB Electrode Saver

Customer’s Challenge:

In semiconductor IC final test, traditional pogo pins and other test probe pins damaged the PCB test board electrodes due to the high contact force.

UPT’s Solution:

As a probe pin saver, UHSS® was placed between the test probe pins and the PCB test board electrodes, and effectively prevented damage to the PCB.

Use-Case4

Recessed Electrode Saver

Customer’s Challenge:

On semiconductor IC final test, the electrodes of PCBs or electronic components recessed under solder resist or solder mask often made contact difficult with traditional silicone rubber sockets.

UPT’s Solution:

UHSS® was placed between the recessed electrode and the silicone rubber socket. This placement ensured stable contact thanks to the UHSS® shape with raised plating.