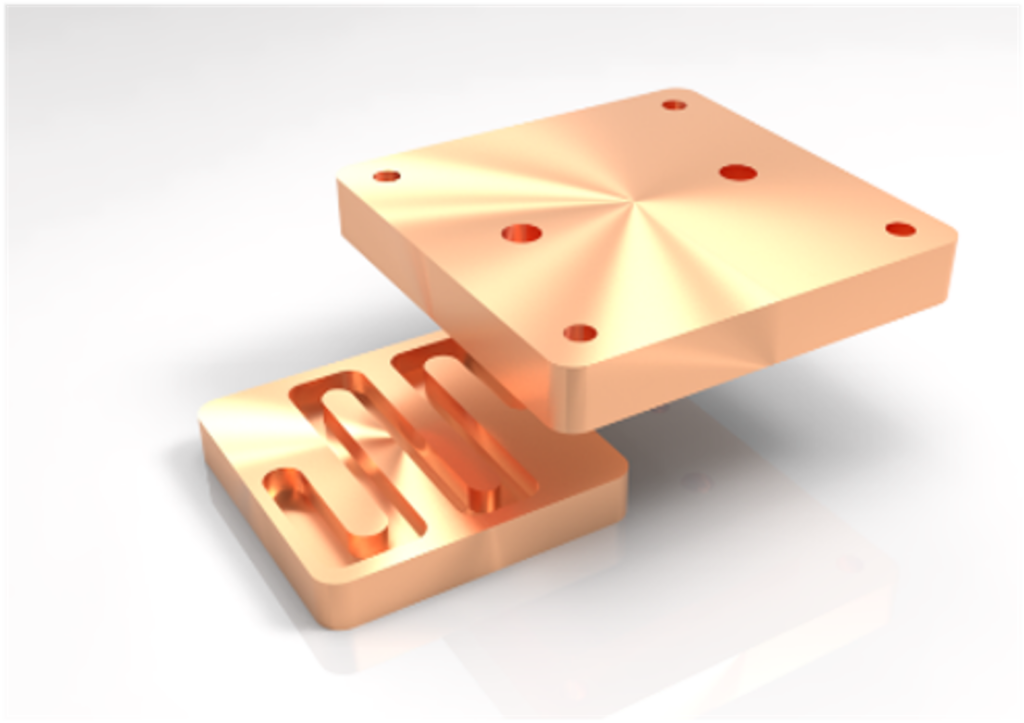

Cold Plate Offering Outstanding Thermal Conductivity and Reliable High-Power Cooling

Copper cold plates are widely used in applications that require extremely high thermal performance.

With a thermal conductivity of approximately 385 W/m·K—nearly twice that of aluminum—copper enables exceptional heat transfer and is ideal for high-power devices and concentrated heat sources.

Although copper is significantly heavier and more expensive, its superior thermal properties allow for efficient cooling even under demanding operating conditions.

Its machinability is moderate, but advanced processes such as diffusion bonding can achieve highly optimized internal flow paths.

Copper also offers stable performance across a broad temperature range, making it suitable for semiconductor equipment, power electronics, and other high-heat-density systems.

When plated or treated to improve corrosion resistance, copper cold plates deliver long-term reliability in critical applications.

Comparing Copper, Aluminum, and Stainless Steel Cold Plates

Selecting the appropriate cold plate material depends heavily on thermal performance requirements, weight limitations, corrosion resistance, and cost. Copper stands out for its extremely high thermal conductivity, making it the best choice for high-power or high-density heat generation environments.

Aluminum provides a more balanced combination of weight, cost, and machinability and is typically used when ultra-high performance is not required. Stainless steel, despite its lower thermal conductivity, offers superior chemical resistance and mechanical strength, which is beneficial in harsh or specialized environments.

A comparison table helps highlight the strengths and trade-offs of each material for informed decision-making.

| Item | Copper | Aluminum | Stainless Steel |

|---|---|---|---|

| Thermal Conductivity (W/m·K) | ~385 | ~205 | ~15 |

| Density (g/cm³) | 8.96 | 2.7 | 7.9 |

| Machinability | Moderate–difficult | Excellent | Moderate |

| Corrosion Resistance | Moderate (requires treatment) | Good (improved with anodizing) | Excellent |

| Cost | High | Low | Medium–high |

| Weight | Heavy | Light | Relatively heavy |

| Typical Applications | High-power cooling, semiconductor tools | General electronics, automotive, telecom | Chemical environments, high-strength applications |

UPT’s Core Technologies Used in Liquid Cold Plates

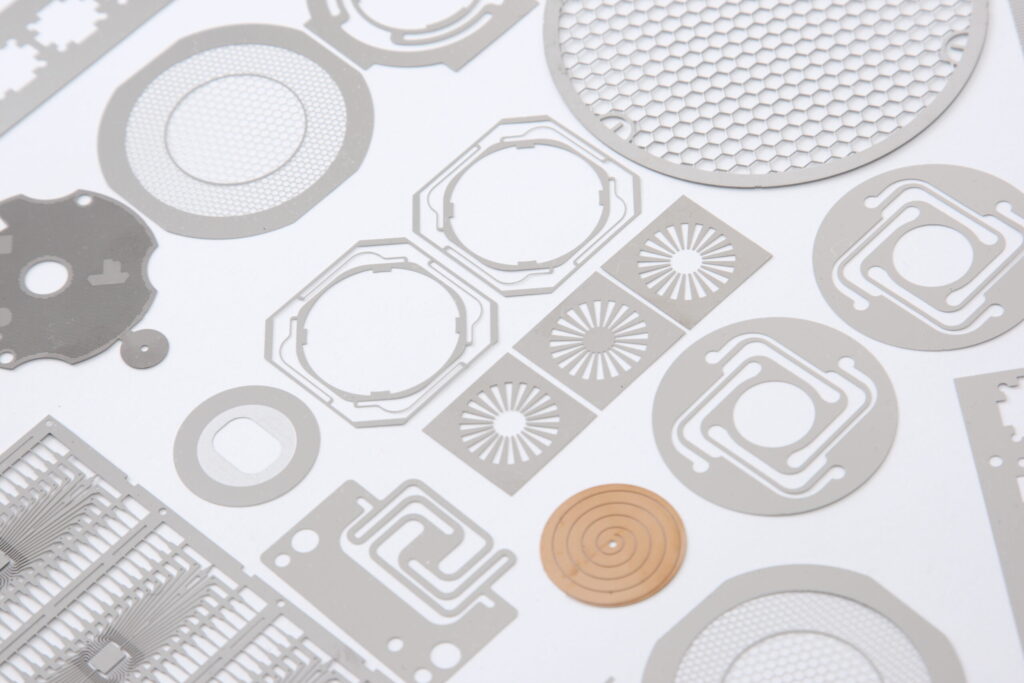

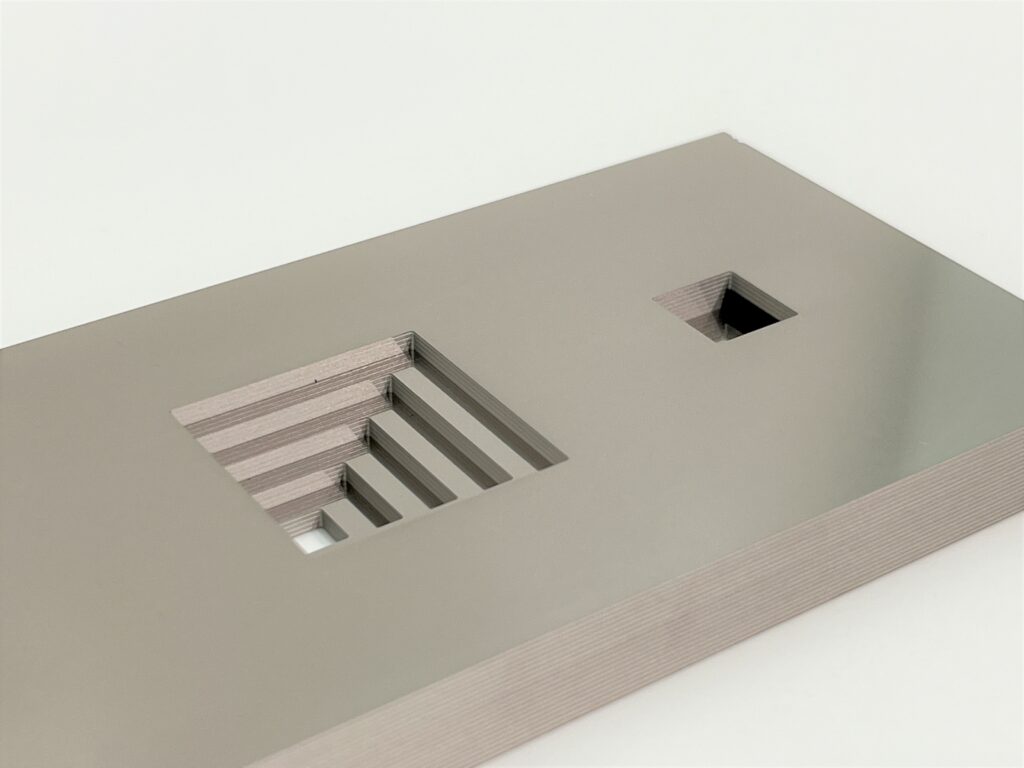

UPT combines photo etching and diffusion bonding technology to manufacture cold plates. This combination offers superior heat dissipation and design flexibility compared with other methods.

Photo etching is the process of using corrosive chemicals to melt specific areas on a metal sheet, resulting in precise, unique and intricate metal parts. This allows for the formation of complex channel structures, enhancing the thermal dissipation efficiency of the coolant.

Diffusion bonding is a bonding technique that joins metals at the atomic level by bringing their surfaces close together. It allows for the highly precise creation of metal parts with complex 3D internal structures. Adhesives and spot welding are also commonly used to bond metals, but these techniques have drawbacks such as cleaning difficulties, peeling at high temperatures, and leaving gaps. The combination of photo etching and diffusion bonding technology produces high cooling performance.

Use Cases of Cold Plates

UPT has solved thermal issues in various fields. Here are some examples:

Use Case 1: Cold Plates for Semiconductor Manufacturing Equipment

Customer Challenge:

As power levels increase, devices can overheat and fail without proper thermal management. Therefore, semiconductor manufacturing equipment requires cold plates with high cooling performance.

UPT’s Solution:

UPT provides high-performance cold plates engineered through proprietary design, utilizing etching and diffusion bonding to meet the customer’s specific requirements.

Use Case 2: Cold Plates for Supercomputers

Customer Challenge:

Increasing cold plate weight can raise installation and maintenance costs for supercomputers. The customer wanted to reduce size and weight while maintaining performance.

UPT’s Solution:

UPT delivered compact, lightweight cold plates that still provide high cooling performance.

Custom Cold Plate Designs

UPT offers custom-designed cold plates. Please contact us if you are facing challenges such as insufficient cooling capacity or limited design flexibility with your current methods.