Water-Cooled Heat Sinks with Flexible Flow Path Design with Photo Etching and Diffusion Bonding Technology

Water-cooled heat sinks are cooling devices designed to efficiently remove heat from high-performance components such as CPUs, GPUs, and ASICs in electronic equipment. Using a water-based coolant, they maintain low operating temperatures and provide highly effective thermal management.

Their structure typically consists of a copper or aluminum body, a coolant that absorbs heat, a pump for circulation, a radiator for heat dissipation, and tubing to complete the cooling loop.

UPT provides high-performance water-cooled heat sinks by leveraging photo-etching and diffusion-bonding technologies.

Principle and structure of Water-cooled heat sinks

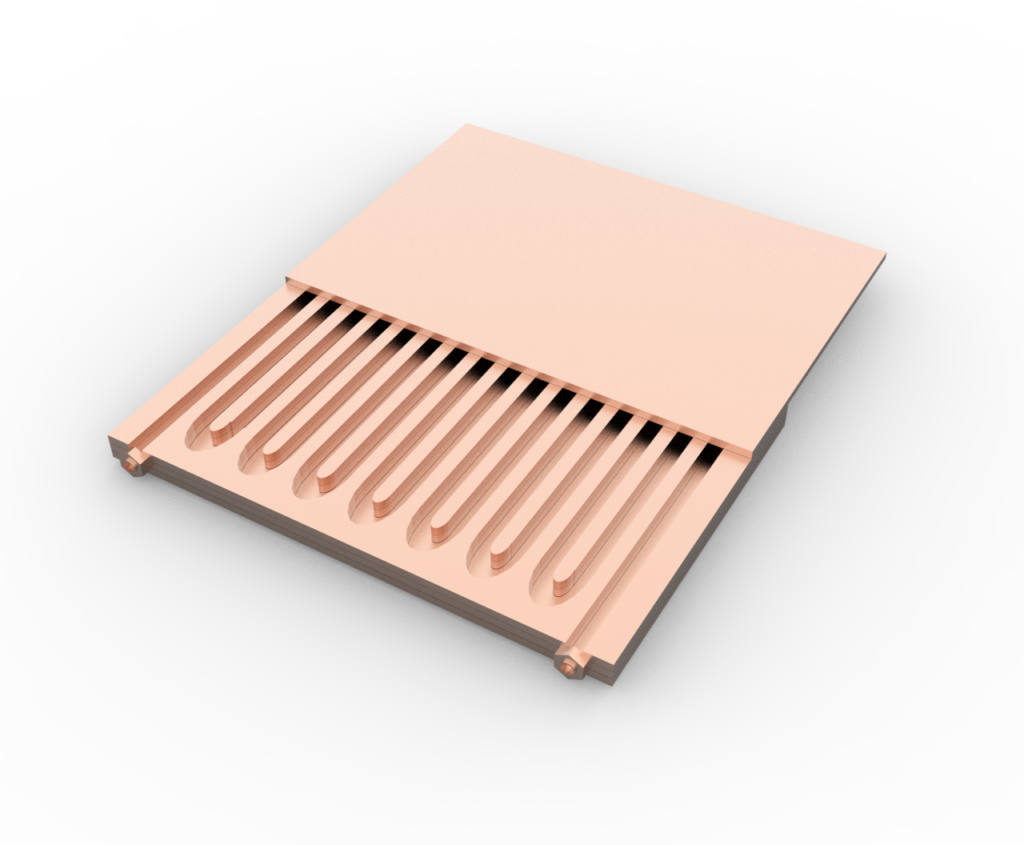

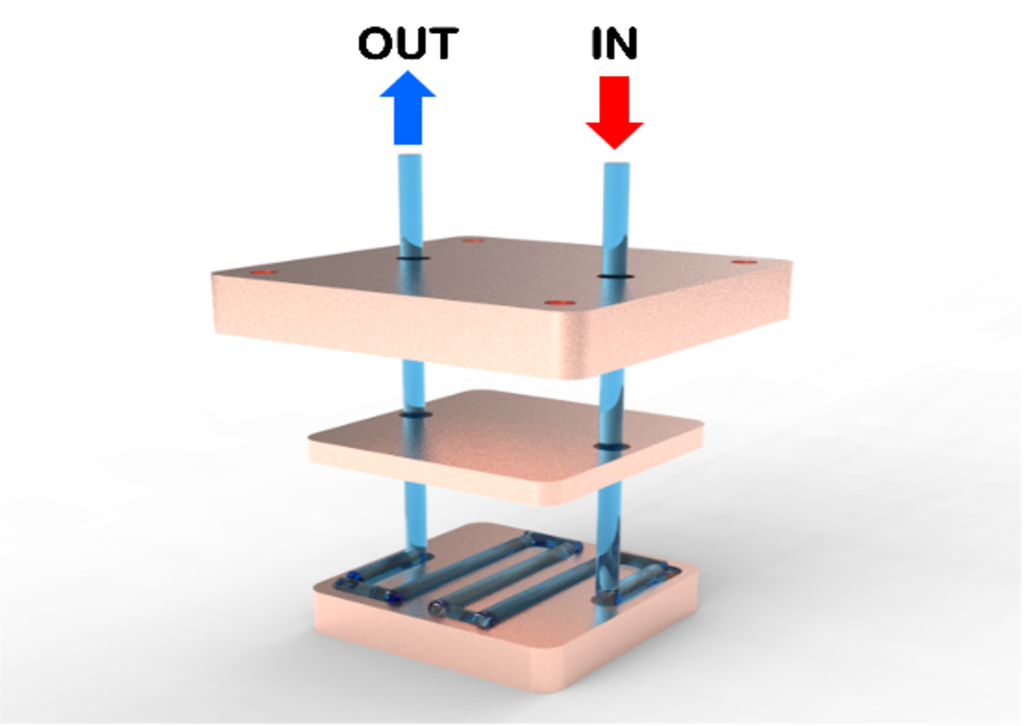

A Water-cooled heat sinks consists of a heat transfer section that transfers heat from a high-heat generating device and a flow path (heat transfer section) that transfers the heat that has passed through the heat transfer section to the cooling water.

As a basic device cooling system, a pump is connected to the water-cooled heat sinks to flow the cooling water, and a radiator (heat exchanger) is connected to dissipate the heat of the cooling water heated by the heat emitted from the device and cool it again, circulating the cooling water.

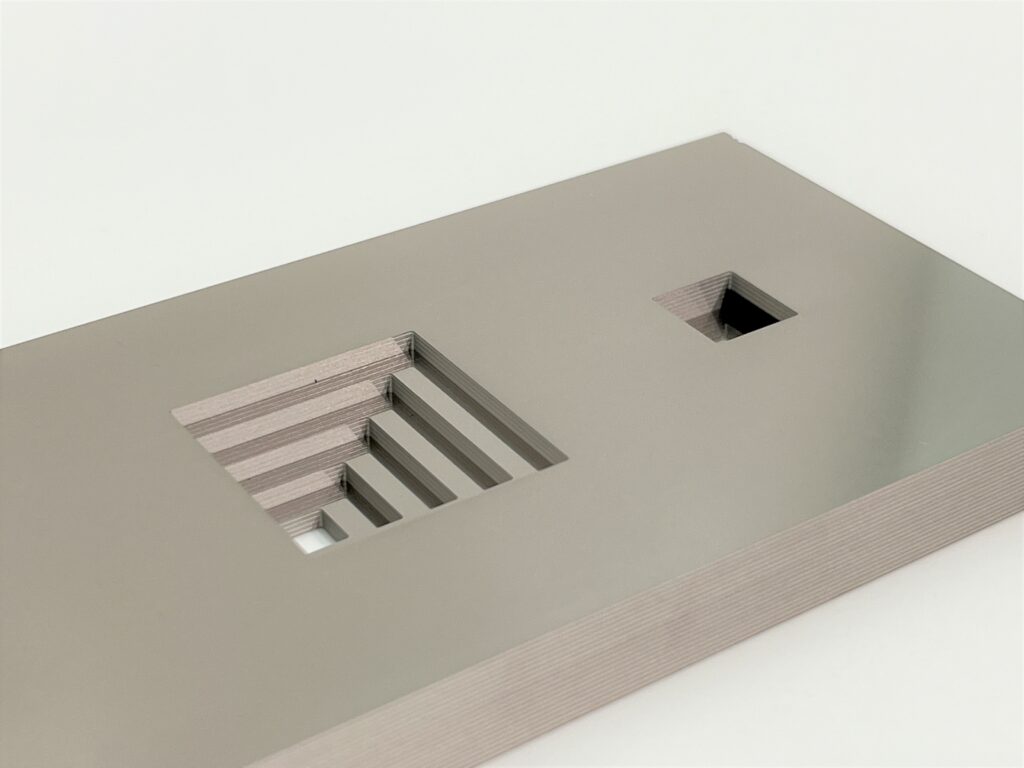

UPT can manufacture this water-cooled heat sinks using thin-plate etching and diffusion bonding technology that overlaps many thin-plate etchings, instead of the conventional cutting process, which enables the formation of flow paths with complex three-dimensional shapes, and also applies flow path surface processing to reduce the heat transfer coefficient with the cooling water to achieve both low thermal resistance and low thermal capacity. This realizes water-cooled heat sinks .

Furthermore, we can provide water-cooled heat sinks that are easier for customers to use by manufacturing hybrid type water-cooled heat sinks by diffusion bonding, which combines metallic materials and high thermal conductive metallic materials that eliminate the need for maintenance of flow paths.

UPT’s Core Technologies Used in Water-Cooled Heat Sinks

UPT designs, manufactures and sells water-cooled heat sinks by combining the elemental technologies of photo-etching and diffusion bonding.

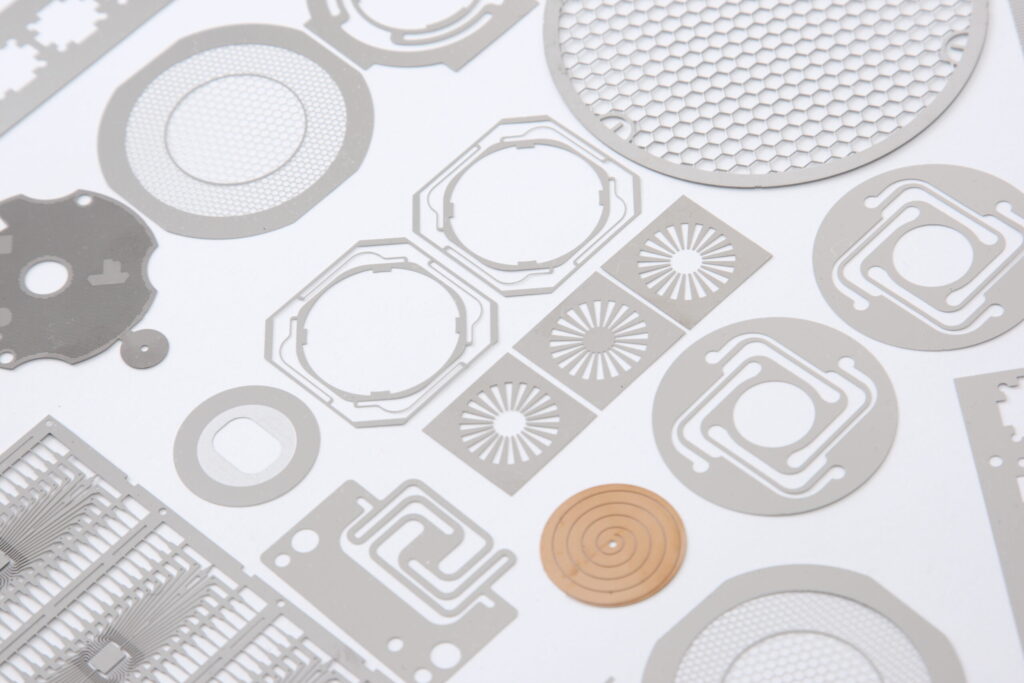

Photo-etching technology uses an etchant to chemically react and corrode metal to enable precision processing of thin metal substrates.

Diffusion bonding technology allows metal surfaces to be bonded together at the atomic level, resulting in a 3D structured metal part. This technology enables 3D channel structures that are difficult to machine to form metal structures with no gaps.

The combination of these two technologies enables the production of products that simultaneously achieve low thermal resistance and low thermal capacitance, which results in high cooling performance, durability, and greater design freedom than other manufacturing methods.

This makes it a superior technology for high performance applications and customization requirements.

- Formation of complex flow paths and hollow structures that cannot be achieved by cutting or other methods.

- Bonding technology that does not use brazing or adhesives, realizing a structure that is highly resistant to component deformation and deterioration.

- Diffusion bonding technology at the level of inter-elemental bonding allows for an ideal heat dissipation effect at the bonding surface with no gaps.

Applications and Uses of Water-Cooled Heat Sinks

Water-cooled heat sinks are essential cooling technologies used in the fields of electronics and semiconductor manufacturing.

Supercomputers

Generate large amounts of heat when processing high-load tasks. Water-cooled heat sinks can efficiently remove heat compared with air cooling, maximizing performance and extending component lifespan while reducing system noise.

Data Centers

In high-density server environment, efficient cooling is crucial. Water-cooled heat sinks effectively manage temperature within data centers, ensuring stable server operation and reducing downtime risks.

Industrial Equipment

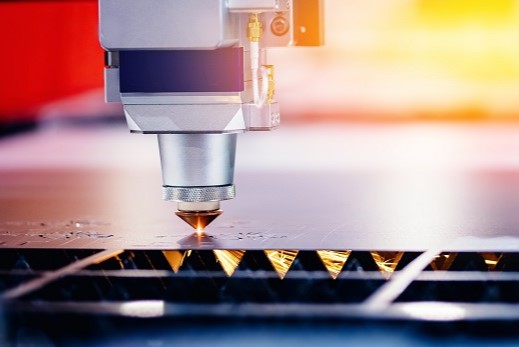

Many industrial machines generate significant heat due to high output. Water-cooled heat sinks are suitable for efficiently cooling these machines, helping to maintain performance and extend lifespan. Stable cooling capability in laser processing machines contributes to maintaining performance and production efficiency. In power electronics, it prevents overheating-induced failures.

Automotive Industry

(Battery Cooling)

Automotive batteries generate significant heat during extended operation or rapid charging. Water-cooled heat sinks are used for efficient battery cooling, enhancing performance and lifespan. Proper temperature management maximizes vehicle range and ensures safety while reducing battery degradation and maintaining long-term reliability.

FAQ

-

What information should we provide when requesting a quotation for a water-cooled heat sink?

-

To ensure an accurate quotation, please share the following specifications: required cooling performance, heat source layout, heat sink dimensions, preferred manufacturing method (extrusion, machining, or diffusion bonding), coolant type, and expected flow conditions such as inlet/outlet positions, flow rate, and allowable pressure drop.

-

What materials are available for water-cooled heat sinks?

-

UPT provides aluminum (including extruded grades), copper (C1020), stainless steel (SUS series), and hybrid structures combining multiple materials. The optimal material depends on thermal conductivity, corrosion resistance, cost, and operating environment.

-

Can UPT customize the internal flow channel and coolant direction?

-

Yes. We can tailor inlet/outlet locations, flow direction, and channel structures—including extruded microchannels, machined serpentine passages, and diffusion-bonded multi-layer flow paths. Our engineers optimize performance and pressure drop using thermal-fluid simulations.

-

How much cooling performance can be achieved?

-

Performance varies depending on heat density, contact quality, and coolant conditions. UPT’s water-cooled heat sinks can dissipate high heat loads for applications such as power modules, EV inverters, and industrial equipment. We propose designs optimized for your allowable pressure drop and coolant temperature.

-

What coolant types are compatible with water-cooled heat sinks?

-

Common coolants include water, glycol mixtures, and dielectric liquids. Depending on the structure and materials used, we can evaluate compatibility with special coolants required for automotive, semiconductor, or industrial environments.

-

What is the typical lead time for custom water-cooled heat sinks?

-

Lead time depends on the manufacturing process:

- Extruded structures: short lead time when existing profiles are available

- Machined channels: high flexibility with moderate lead time

- Diffusion-bonded microchannel structures: longer lead time due to multilayer fabrication

We will provide a detailed schedule based on design complexity and material availability.

Trust UPT for Custom Water-Cooled Heat Sink Design

UPT specializes in custom design of water-cooled heat sinks. Please contact us If existing methods do not meet your cooling performance needs or if you face challenges with low design flexibility and product integration.