Adjust Cumulative Errors for Precision Equipment

During the assembly of precision equipment, such as semiconductor production equipment (SPE) and molds, cumulative errors that require gap adjustments often occur. In such cases, those adjustments usually require micron-level fine-tuning. Our shim spacers can solve these issues.

What are Shim Spacers?

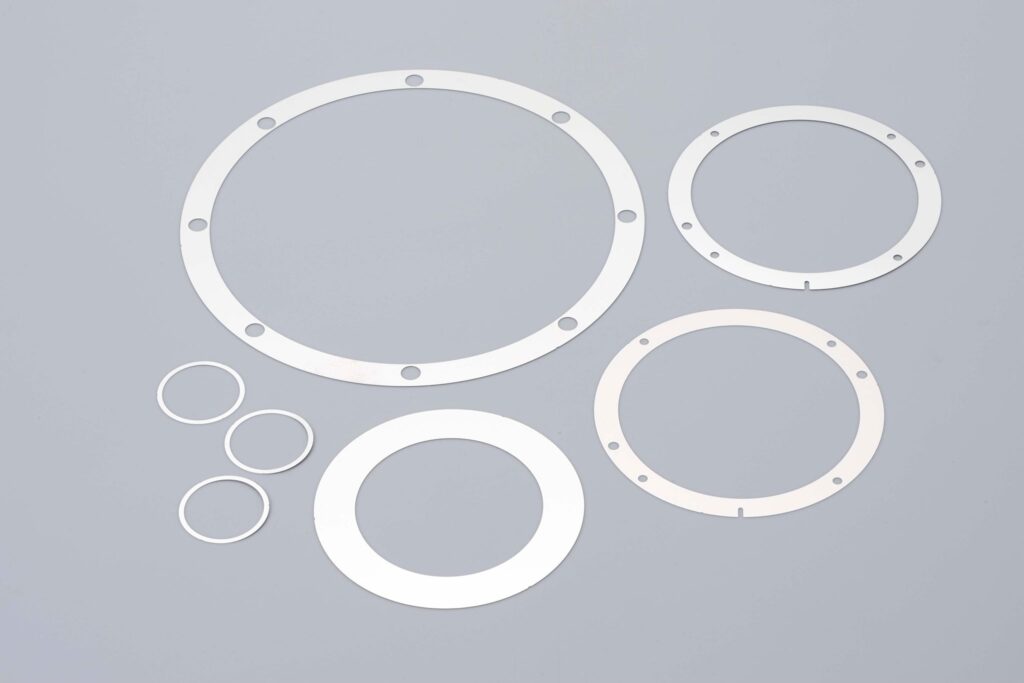

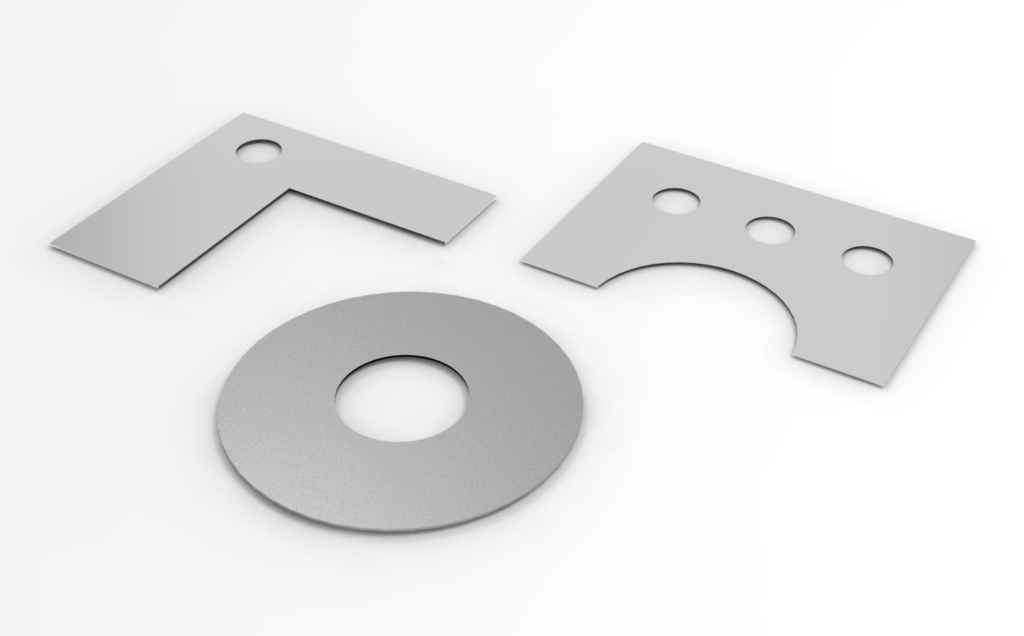

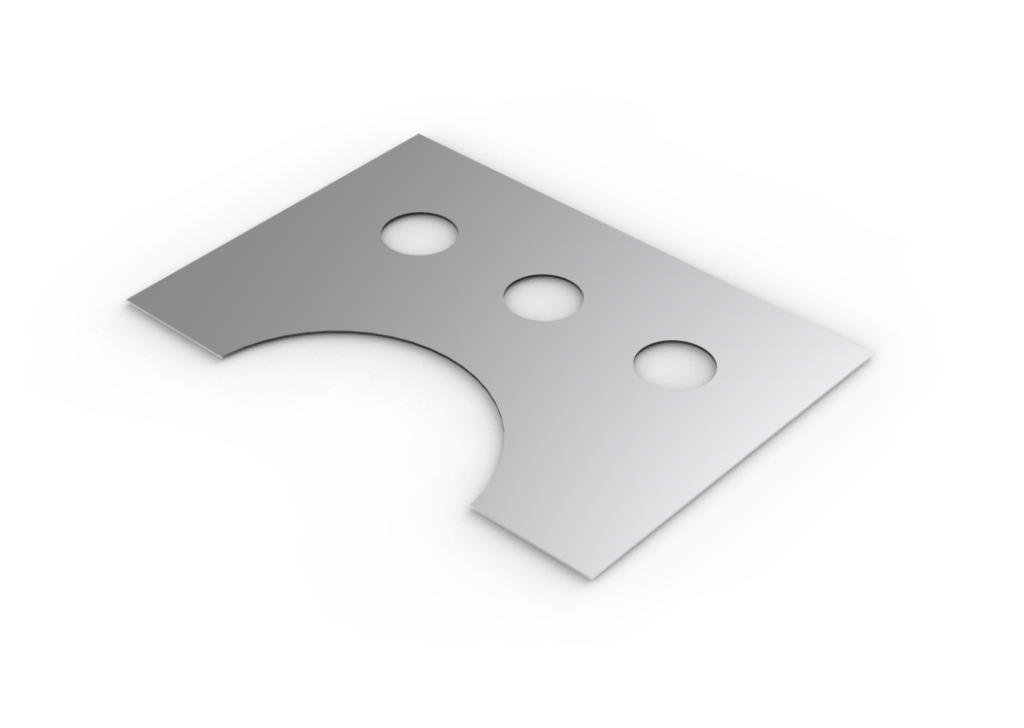

Shim spacers are thin, plate-like metal components to adjust the position of machine parts or fill gaps, and are used in the following situations.

- Precise alignment of machine parts

- Filling gaps between parts

- Absorbing vibrations or shocks from machinery

Shim spacers are often provided as a set with different thicknesses. Users can pick some from the set and combine as needed. It is essential to select the appropriate material and size in accordance with the specific application.

Advantages of UPT’s Shim Spacers

To address fine tuning issues for precision equipment, UPT manufactures highly accurate custom shim spacers by combining photo etching technology with various surface treatments.

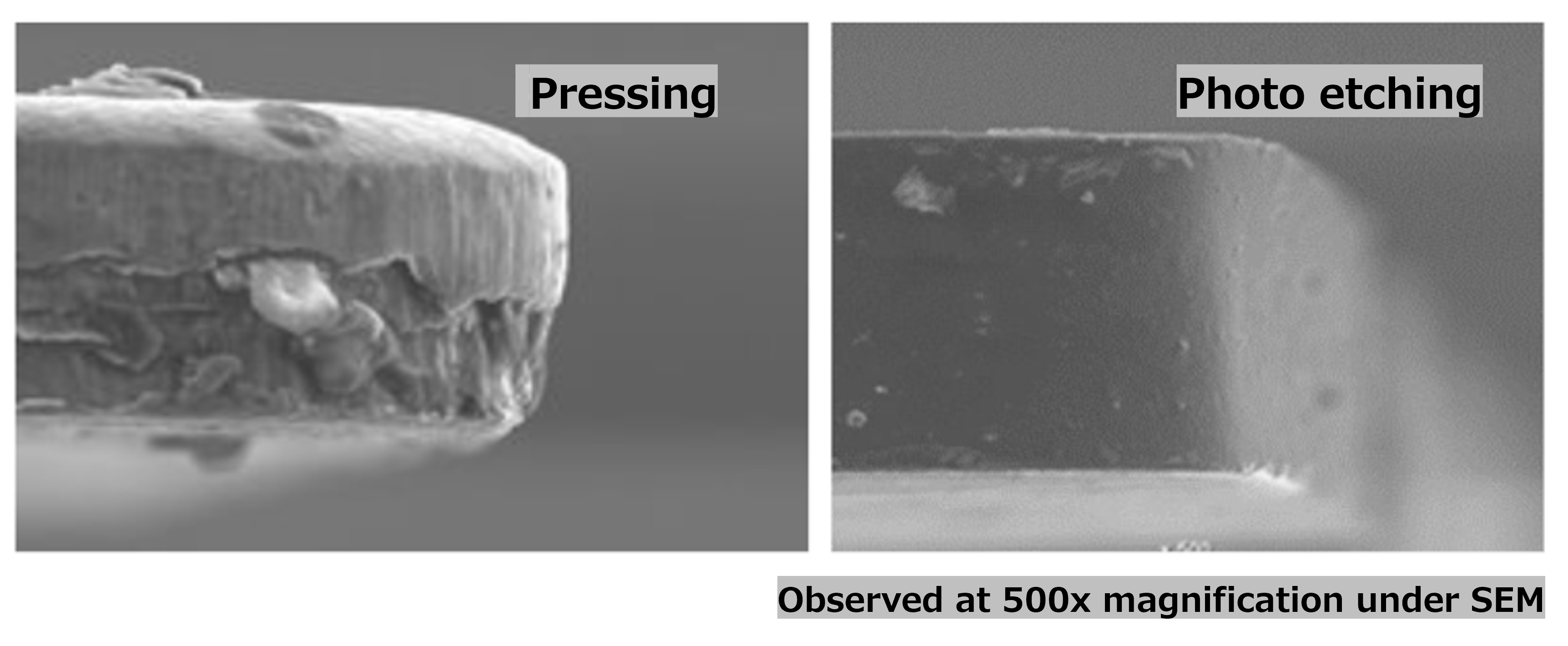

High-Precision Finish by Photo Etching Technology

Photo etching technology does not need force and heat to base material, resulting in a burr-free, deformation-free, and high-precision finish without dross or debris. Additional processes to remove dross or debris are not necessary, allowing for ideal thickness precision starting from 0.004mm.

Handling Thickness, Material Combinations, and Surface Treatments

General metalworking methods have difficulty in processing some combinations of thickness and material types. Additionally, for specialized applications such as optical devices, black coating or black oxide treatment may be required to suppress light reflection and stray light. UPT offers a one-stop service, from photo etching to surface treatment. Photo etching technology needs no mold, reducing costs while preventing burrs and deformation.

Extensive Material Inventory

UPT offers a wide selection of materials and thicknesses from our extensive inventory. Available materials include stainless steel, copper, brass, iron, and aluminum. For stainless steel, we stock materials in 0.005mm increments. UPT can also handle materials such as titanium and magnesium.

Similar Products (Washers) and Other Processing Methods (Pressing and Laser Processing)

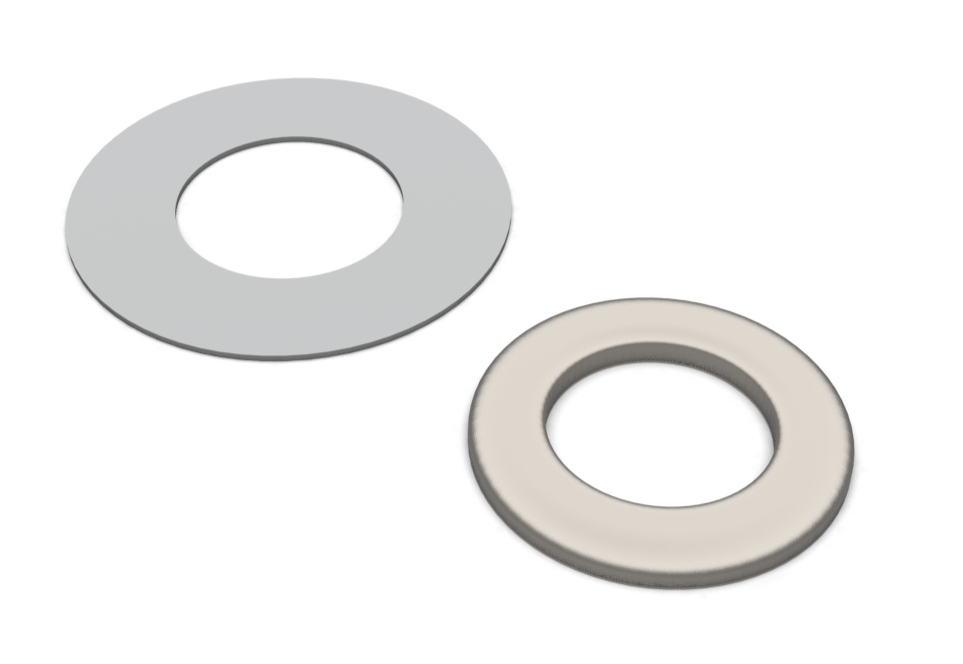

Washers

Shim spacers are much thinner and allow for more precise adjustments than washers, making them particularly effective in situations requiring fine gap or position adjustments. Shim spacers are often customized to meet specific mechanical requirements, such as selecting the most suitable material and shape for a particular application. On the other hand, washers are typically provided in standard sizes and shapes, thus offer less flexibility.

Comparison with Other Processing Methods (Pressing and Laser Processing)

Shim spacers manufactured with photo etching technology offer higher precision than other methods such as pressing or laser processing, and allow for the accurate reproduction of complex shapes and fine details. This advantage makes custom designs for specific applications more feasible.

Additionally, photo etching technology can keep the material properties because it applies less physical stress to the material. This strength is ideal for manufacturing thin parts, and is suitable for the mass production of precision shim spacers.

Use-Cases of UPT’s Shim Spaces

UPT has successfully addressed the challenges of adjusting the position of mechanical parts and filling gaps in various industries.

Use-Case 1:

Shims Plates for SPE (Material: SUS304, Thickness: 0.01mm)

Customer’s Challenge

Shim plates were manufactured using laser processing. Laser processing is unsuitable for thin shim plates, so the customer was not able to achieve desired thickness and shape. Plus, the customer had issues with delivery times.

UPT’s Proposal

UPT offered shim plates with thickness adjustments in 0.005mm increments using photo etching technology. The customer achieved desired 0.005-0.01mm shims and short delivery times.

Use-Case 2:

Shim Plates for Measuring Equipment (Material: SUS304, Thickness: 0.05mm)

Customer’s Challenge

Shim plates manufactured with pressing had burrs.

UPT’s Proposal

Photo etching technology makes no burrs, and can make high precision shims that enables finer gap adjustments.

Use-Case 3:

Ring / Round Shims for Optical Components in Cameras (Material: SUS304 with black oxide treatment, Thickness: 0.01mm)

Customer’s Challenge

The customer made orders to multiple sppliers to produce ring shims with surface treatment, and suffered from handling complicated process control.

UPT’s Proposal

UPT provided one-stop service from photo etching to black oxide treatment. The customer was released from handling complicated process control, and even reduced lead times and costs.