The increasing demand for precision parts in the electronic component industry is driving innovation. With our specialized expertise in precision metal fabrication, we’re here to transform your ideas into tangible, high-quality industrial components that optimize a wide range of industrial applications. If you have a project in mind, don’t hesitate to reach out to us for more information and personalized solutions tailored to your specific needs.

Optical Parts Photo etching + Black Plating

Optical parts play a crucial role in equipment, ensuring optimal performance and functionality. With our sheet-based photo etching process, you can efficiently achieve cost-effective solutions tailored to your needs.

We provide plating treatments to prevent reflection in optical parts. In addition to plating, we also offer painting and coating options, allowing us to recommend the most suitable treatment based on your precision requirements.

Printer Heads

We manufacture components for copiers and printer heads, catering to various applications in both consumer and large-scale industrial sectors. Our expertise extends to the production of various components, including grit plates and discharge pins, which are essential for these devices.

In the realm of printer heads, precision is of utmost importance. Achieving accurate and consistent printing results relies heavily on the quality and precision of the components used. Whether you require components for consumer-grade printers or industrial-scale printing equipment, our precision solutions are designed to meet your specific needs. If you’re looking to optimize any specific requirements, we welcome the opportunity to discuss and tailor our offerings to your preferences.

Semiconductor Package Parts

We specialize in the production of various semiconductor package components, such as lead frames designed for ICs and LSIs, along with a variety of heat spreaders optimized for efficient heat dissipation. Our heat spreaders can be plated with nickel or gold, or coated with resin on one side, enhancing their heat management capabilities. This ensures that your semiconductor components consistently deliver optimal functionality and thermal efficiency.

With our photo etching process, we have the flexibility to work with a wide range of materials, including copper alloys and 42 alloys, offering thicknesses spanning from 0.05t to 0.76t. This method not only guarantees precision and accuracy but also allows for customization, cost-effectiveness, and reduced lead times, making it the ideal choice to support your fabrication needs.

Talk to Us about Your Project

Since our industrial parts are fully customizable to fit your device/equipment, please don’t hesitate to reach out to us with your ideas.

Encorders + Black Plating

Rotary encoders are engineered to provide precise measurements for parameters like rotation quantity, angle, and position. Precision is a key factor in the performance of encoders, ensuring accuracy in various applications.

To benefit our customers, we’ve optimized our production processes, especially for high-volume items, resulting in cost-effective solutions without compromising quality. If you have any specific requirements in mind, please reach out to us for a consultation. Your feedback and input are invaluable as we strive to deliver high-quality rotary encoders that align with your expectations and budget.

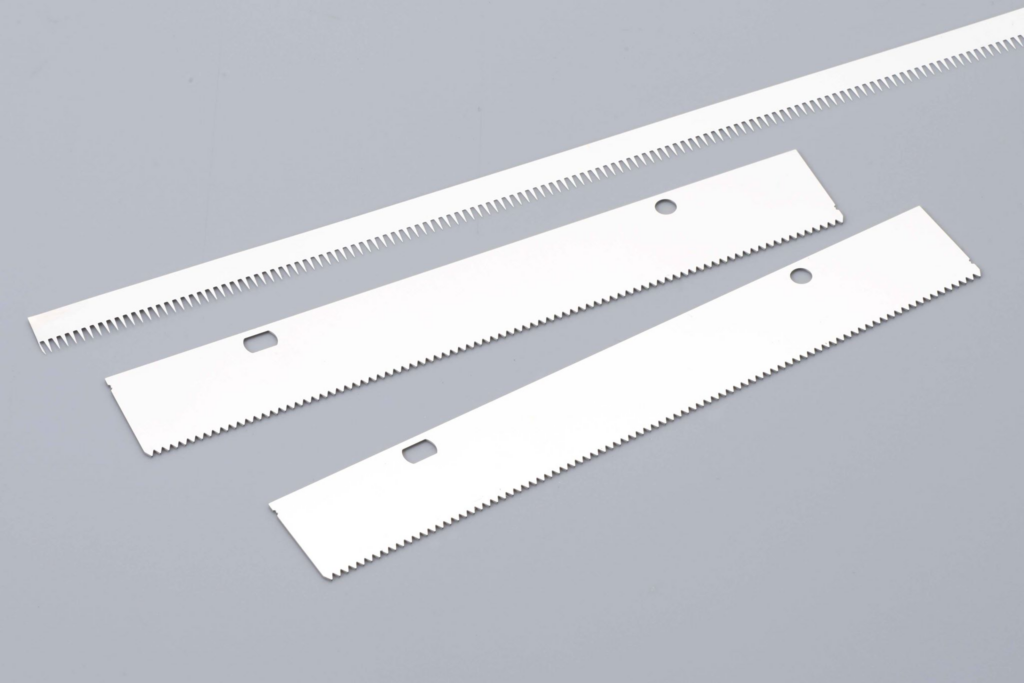

Cutter parts

Due to the inherent characteristics of etching processes, achieving a minimal tip radius is often a challenge. However, we have developed proprietary techniques and expertise to significantly reduce the tip radius, optimizing the performance of cutter parts.

Our advanced etching methods can even accommodate applications that require sharp-tip configurations. We encourage you to explore the possibilities of our etching processes for cutter parts, where precision and customization are paramount. Your unique requirements can be met with our innovative solutions.

Sims and Spacers

Our precision spacers are available in various thicknesses with a thickness accuracy of ±0.002 (using stainless steel material). These spacers find applications in mobile phones, particularly for auto-focus actuators, and various spiral springs.

Maintaining high precision in manufacturing processes is essential for the quality and performance of these components. We have established production capabilities to accommodate high-volume manufacturing, ensuring consistent quality and timely delivery.

Moreover, we offer secondary processing options, such as thickness adjustment and blackening treatment, providing comprehensive solutions tailored to your specific needs. If you have any specific requirements or need assistance with cost optimization, please don’t hesitate to reach out to us. We’re here to support your objectives.

UPT Advantages

- Precision Tolerance Control through Photo Etching Expertise

With our specialization in photo etching, we excel in achieving and maintaining tight tolerance control. Our expertise ensures that your components meet the most stringent precision requirements, even in high-precision applications. - Production Flexibility with Stringent Quality Control

Serving a global smartphone manufacturer as our end user, we understand the importance of flexibility of production. Our capabilities allow us to seamlessly scale up production while maintaining stringent quality standards. This ensures that your components meet the rigorous demands of global supply chains without compromising on quality. - Comprehensive One-Stop Solution

Beyond our core competencies in photo etching and diffusion bonding, we offer a complete one-stop solution for your production needs. Whether you require additional processes such as plating or machining, we take care of the coordination and management of all necessary technical suppliers. This simplifies your production workflow, streamlining the process and ensuring that your ideal production is achieved efficiently.

Talk to Us about Your Project

Since our Processing Jig is fully customizable to fit your device/equipment, please don’t hesitate to reach out to us with your ideas.