The demand for smaller pin-pitches and increased pin counts in semiconductor/electronic component testing and device packaging is driven by several factors, including the miniaturization of semiconductor devices, the need for higher pin counts, and the growing demand for high-speed data transfer. With a proven track record as specialists in high-precision metalfabrication expertise and the distinction of holding the top market share for VCM smartphone camera parts, we’ve harnessed our wealth of experience to engineer precision metal contacts for electronic testing.

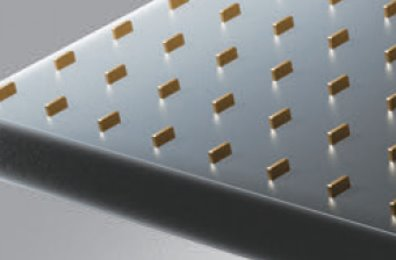

Rubber Sheet _Micro Metal Socket®

The demand for smaller pin-pitches and increased pin counts in semiconductor testing and device packaging is driven by several factors, including the miniaturization of semiconductor devices, the need for higher pin counts, and the growing demand for high-speed data transfer. These developments are critical to meet the diverse requirements of various applications and markets. In response to these demands, UPT has developed the Micro Metal Socket® (MMS), featuring silicone rubber sockets with specially designed metal pins. The MMS offers multiple-pin silicon sockets with exceptionally low force, small pitch, long-term durability, and customizable layouts.

Features of Micro Metal Socket® (MMS)

- Supports High Frequency Range and High Speed Transmission

Short Height 0.5mm~ - Small pitch 0.3㎜~

- Low force

Talk to Us about Your Project

Since our MMS is fully customizable to fit your device/equipment, please don’t hesitate to reach out to us with your ideas.

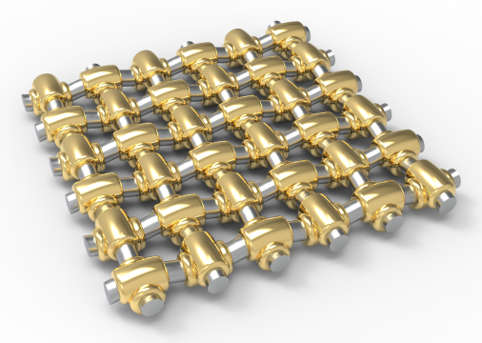

Ultra Thin Conductive Sheet _ UHSS®

Pioneering a revolutionary solution in anisotropic conductive sheets, UPT introduces ‘Union High Speed Sheets (UHSS),’ harnessing advanced photo etching technology. Thanks to its thinness, UHSS excels in high-speed data transmission, making it a top choice for demanding applications.

Features of UHSS®

- Ultra Thin 50 μm~

UHSS is very thin, making them suitable for applications with space constraints. - High-Speed Data Transmission

UHSS is suitable for high-speed data transmission, making it ideal for cutting-edge 5G and high-speed connectivity applications. - Current Tolerance 3A

UHSS excel in current tolerance, making them suitable for applications where electrical current demands are significant. - Frequency Bandwidth

UHSS offers excellent frequency bandwidth capabilities, ensuring reliable signal transmission across a broad spectrum of frequencies. - Robust Connectivity

UHSS offers robust and reliable electrical connections, ensuring consistent signal transmission even in demanding applications. - Customizable Layouts

The sheets can be customized in terms of size, shape, and pitch to match specific application requirements. - Wide Range of Applications

UHSS is versatile and suitable for use at various levels of electronic testing and production, including wafer, package, and system levels.

Talk to Us about Your Project

Since our UHSS is customizable to fit your device/equipment, please don’t hesitate to reach out to us with your ideas.

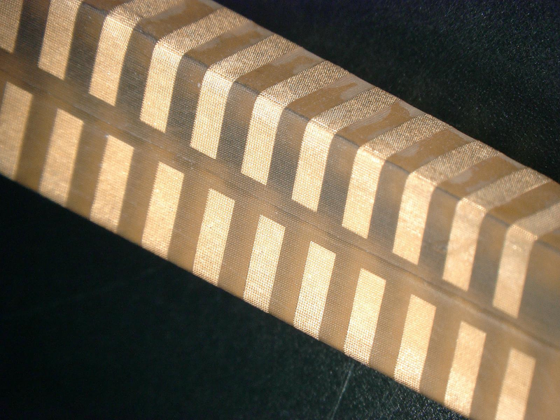

Shock-Absorbing Contact Block_MPC Block™

The MPC Block seamlessly combines the ultra-thin profile and robust connectivity of UHSS with the elasticity, shock-absorbing properties, of silicon. This unique combination proves highly effective in safeguarding delicate components from mechanical stresses and potential damage.

- Protection Against Mechanical Stresses or Potential Damage

Electronic devices are often subjected to various mechanical stresses, including touch-down forces during electronic testing. These stresses have the potential to harm delicate components. MPC Blocks were specifically developed to offer a cushioning and shock-absorbing solution, safeguarding these components from potential damage.

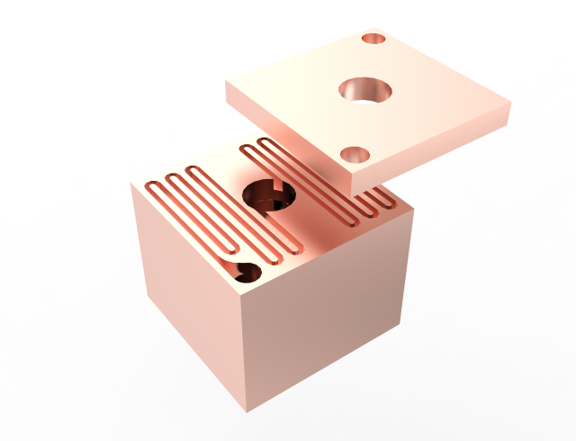

Cold Plate with Microchannel for Thermal Solutions _ Union Cooling Tech®

Driven by the miniaturization of electronic devices, increased power density, high-performance computing demands, and higher data transfer rates, the quest for efficient thermal management solutions in next-generation electronic components and devices has intensified.

At UPT, we offer advanced thermal management solutions featuring microfluidic structures—a feat not easily achievable through conventional processes.

Features of Cold Plate with Microchannel

- Enhanced Heat Dissipation: Microfluidic channels and structures enhance heat dissipation by efficiently circulating coolant or liquid through the channels. This results in improved temperature regulation, preventing overheating and ensuring optimal electronic performance.

- Precise Temperature Control: Microfluidic systems offer precise temperature control within electronic components. This level of precision is crucial for maintaining the stability and reliability of sensitive electronic devices.

- Uniform Cooling: Microfluidic structures provide consistent, uniform cooling across the entire surface of electronic components. This eliminates hotspots and ensures consistent thermal management, even in complex and densely packed electronic assemblies.

- Compact Form Factor: Microfluidic systems are inherently compact and can be seamlessly integrated directly into electronic components or assemblies. This saves space and minimizes the overall footprint of the device, optimizing its design.

Talk to Us about Your Project

Since our our cold plate is customizable to fit your device/equipment or requirements, please don’t hesitate to reach out to us with your ideas.

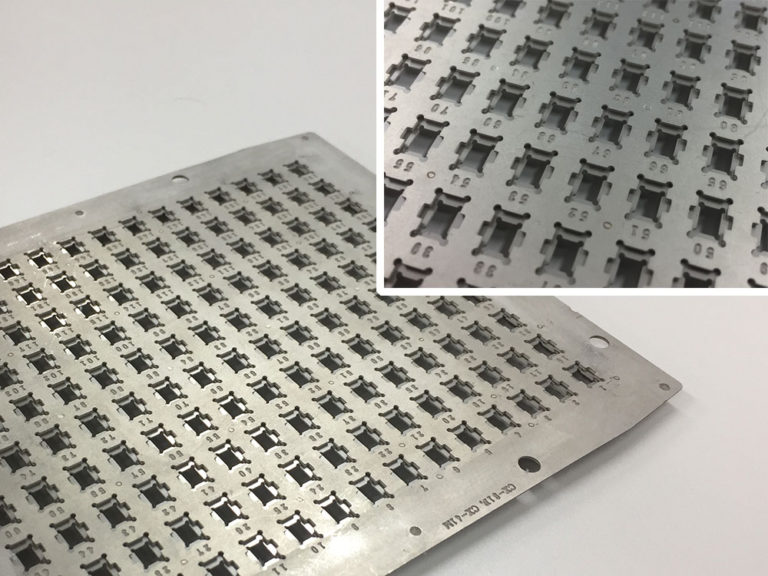

Processing Jig Tray _ Union Tray®

Engineered for durability with diffusion bonding, our trays excel in demanding production environments, ensuring long-lasting performance. Benefit from superior dimensional stability with our Jig Trays, a critical feature for micro-size electronics production. Seamlessly integrating into automated lines, our Jig Trays reduce setup time and significantly boost productivity. Experience impeccable quality control through precise handling, guaranteeing that every component meets your exacting standards.

- Unmatched Precision &Customization

Photo etching allows for intricate and precise designs, ensuring that each processing jig tray can be tailored to meet the exact specifications and requirements of your components. - Cost-Effective

The absence of expensive molds or tooling reduces initial setup costs, making it a cost-effective solution for both prototyping and mass production. - Durability

The combination of materials and bonding techniques ensures that the processing jig trays have a long lifespan and can endure harsh manufacturing environments. - Short Lead Times

Photo etching and diffusion bonding processes are relatively quick, allowing for shorter lead times in production, which is crucial for time-sensitive projects. - Dimensional Stability

Photo etching and diffusion bonding processes maintain the dimensional stability of the processing jig trays over time, ensuring consistent and accurate results during component production.

Talk to Us about Your Project

Since our Union Tray® is customizable to fit your device/equipment, please don’t hesitate to reach out to us with your ideas.