Thermal management solutions with Fluidic Structure

Driven by the miniaturization of electronic devices, increased power density, high-performance computing demands, and higher data transfer rates, the quest for efficient thermal management solutions in next-generation electronic components and devices has intensified.

At UPT, we offer advanced thermal management solutions with the precision of photo etching and the strength of diffusion bonding. Our solutions deliver exceptional durability and versatility, from prototyping to mass production.

One of the key advantages is its time-effectiveness. Unlike conventional methods that require specialized and costly molds, our approach accelerates your prototyping phase, allowing for faster progress.

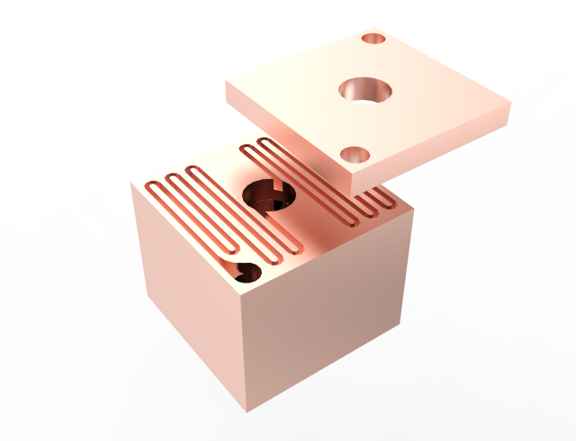

Cold Plate with Microchannel by Photo Etching + Diffusion Bonding

UPT offers advanced thermal management solutions featuring microfluidic structures—a feat not easily achievable through conventional processes.

- Enhanced Heat Dissipation: Microfluidic channels and structures enhance heat dissipation by efficiently circulating coolant or liquid through the channels. This results in improved temperature regulation, preventing overheating and ensuring optimal electronic performance.

- Precise Temperature Control: Microfluidic systems offer precise temperature control within electronic components. This level of precision is crucial for maintaining the stability and reliability of sensitive electronic devices.

- Compact Form Factor: Microfluidic systems are inherently compact and can be seamlessly integrated directly into electronic components or assemblies. This saves space and minimizes the overall footprint of the device, optimizing its design.

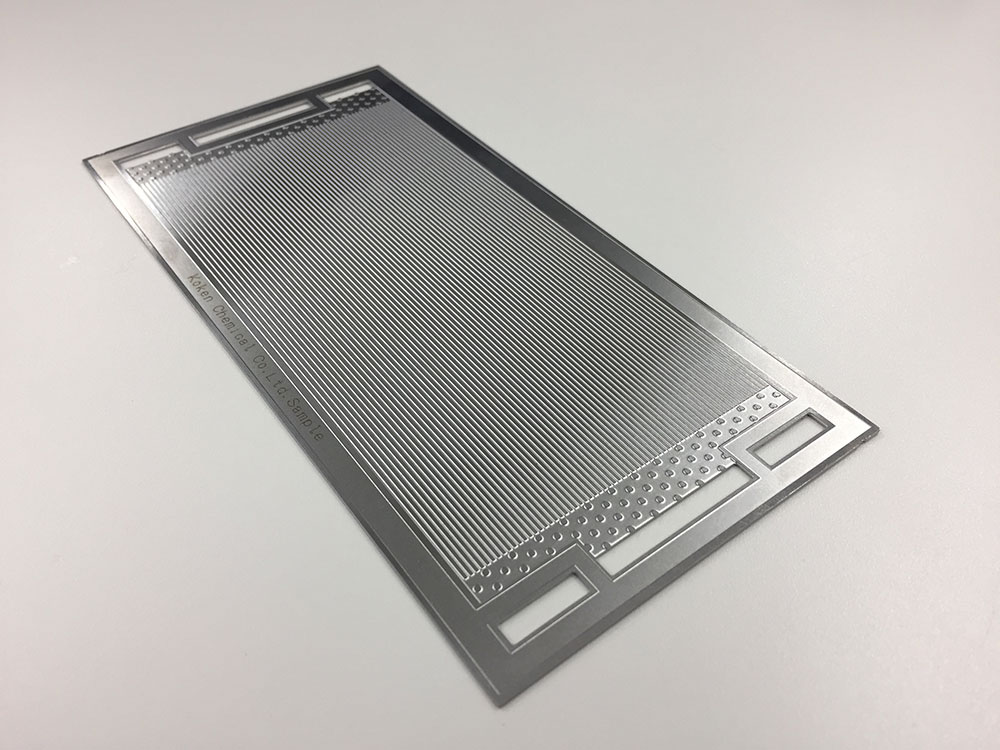

Cooling Plate by Photo Etching + Diffusion Bonding

By integrating etching and diffusion bonding techniques, we provide cooling plates that are versatile, suitable for both water-cooling and air-cooling systems. These cooling plates are designed to accommodate a broad spectrum of applications, ranging from compact heat sinks for semiconductor packages to large heat exchangers like those used in hydrogen stations.

- Adhesive-Free Design: Cooling plates manufactured with photo etching and diffusion bonding do not require adhesives or glue for their assembly. This eliminates the risk of adhesive degradation, ensuring long-term reliability and reducing maintenance concerns.

- Reduced Weight and Size: Cooling plates made using these techniques can be lightweight and compact while maintaining high thermal efficiency, which is essential in applications where space and weight constraints are important.

UPT Advantages

- Precision Tolerance Control through Photo Etching Expertise

With our specialization in photo etching, we excel in achieving and maintaining tight tolerance control. Our expertise ensures that your components meet the most stringent precision requirements, even in high-precision applications. - Production Flexibility with Stringent Quality Control

Serving a global smartphone manufacturer as our end user, we understand the importance of flexibility of production. Our capabilities allow us to seamlessly scale up production while maintaining stringent quality standards. This ensures that your components meet the rigorous demands of global supply chains without compromising on quality. - Comprehensive One-Stop Solution

Beyond our core competencies in photo etching and diffusion bonding, we offer a complete one-stop solution for your production needs. Whether you require additional processes such as plating or machining, we take care of the coordination and management of all necessary technical suppliers. This simplifies your production workflow, streamlining the process and ensuring that your ideal production is achieved efficiently.

Talk to Us about your Project

Since our cooling solutions by diffusion bonding and photo etching products are fully customizable to fit your equipment, please don’t hesitate to reach out to us with your ideas.