The increasing demand for magnesium alloys stems from their immense potential for versatile applications across multiple industries. However, it’s important to acknowledge that magnesium processing presents certain inherent challenges. That’s where our photo etching solution comes into play, as it’s tailored to address and overcome these specific challenges, ensuring the effective and efficient use of magnesium in various applications.

Advantages of Magnesium:

①Lightweight

Magnesium stands out as one of the lightest structural metals, making it invaluable for weight-critical applications. With a specific gravity of just 1.7, magnesium surpasses practical metals like aluminum (2.7), titanium (4.5), zinc (7.1), and iron (7.9).

②High Strength-to-Weight Ratio

Despite its low weight, magnesium alloys offer impressive strength, making them suitable for applications requiring structural integrity.

③Low Environmental Impact

Magnesium is recognized for its eco-friendliness, with efficient recyclability reducing manufacturing’s environmental footprint. Its lightweight properties can also contribute to decreased fuel consumption in transportation. Additionally, magnesium’s ability to dissolve in saltwater, hot water, and dilute acids minimizes environmental impact.

④Good Thermal Conductivity

Magnesium alloys possess excellent thermal conductivity, finding applications in industries such as electronics and heat exchangers.

⑤High vibration absorption

Magnesium demonstrates exceptional vibration absorption properties, with purity levels affecting performance, higher purity magnesium exhibiting superior capabilities in this regard.

⑥Minimal dimentional changes

Magnesium undergoes minimal dimensional changes even under thermal stress, with variations of just 6×10^-6 observed after 100 hours of exposure to 150°C. These changes are nearly negligible at temperatures below 100°C.

References The Japan Magnesium Association マグネシウムの基礎知識:特性 | 日本マグネシウム協会日本マグネシウム協会 (magnesium.or.jp) (2023年6月14日閲覧)

Challenges of Magnesium

①Corrosion Susceptibility

Some magnesium alloys are susceptible to corrosion, primarily due to their high ionization tendency. This vulnerability is especially pronounced in harsh environments. To address this issue, protective coatings or alloy modifications may be necessary.

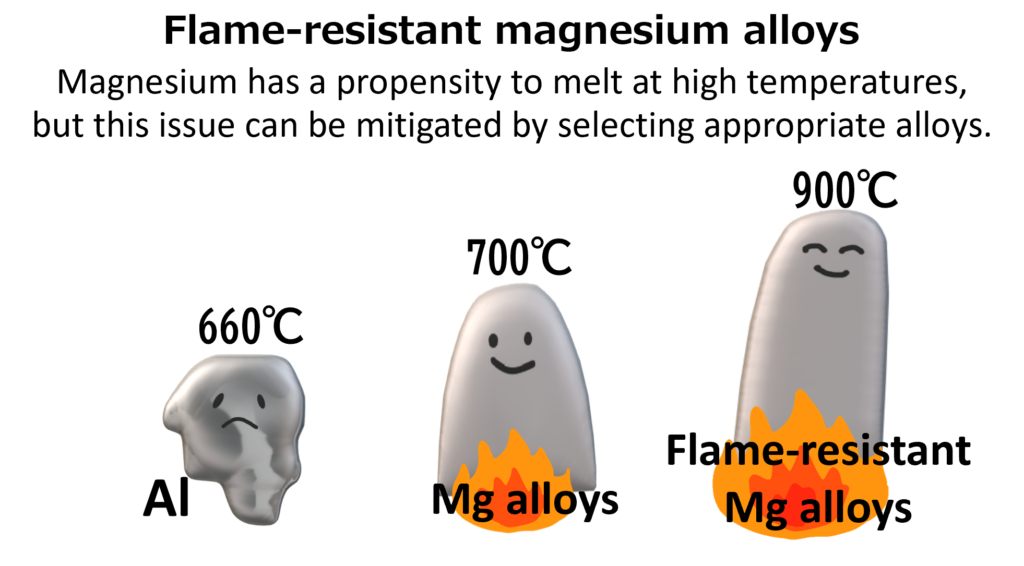

②Flammability

Magnesium is highly flammable, particularly in the form of fine chips or shavings, which can pose safety concerns in certain applications. Preventative safety measures are essential to mitigate fire risks.

③Reactivity in Processing

Magnesium exhibits reactivity with water, acids, and other substances, making it challenging to process, and it is also prone to cracking. These properties can create obstacles when using processing techniques like pressing and machining.

UPT offers

①Corrosion Resistance:

UPT offers a comprehensive service from photo-etching processing to surface treatment, effectively relieving customers of their workload and ensuring corrosion resistance.

②Safeness

Using photo-etching processing is inherently safe and eliminates the risk of fire.

③Processing Challenges

UPT’s extensive network of support assists in selecting the optimal materials and fulfilling customer requirements, making the processing of magnesium less challenging.

UPT offers an all-in-one solution, managing everything from material sourcing to surface treatment as a seamless package.

Consultation

Whether your inquiry is big or small, please don’t hesitate to reach out to us via our contact page. Our sales and engineering team are here to collaborate closely with you and address any challenges you may encounter.

Optimal Material Selection

Thanks to our established business partnerships with various material manufacturers, we can offer tailored solutions to address specific customer concerns. For those prioritizing safety, we propose our flame-resistant magnesium alloys. Additionaly we are actively developing new magnesium alloys designed for deep drawing processing.

Processing

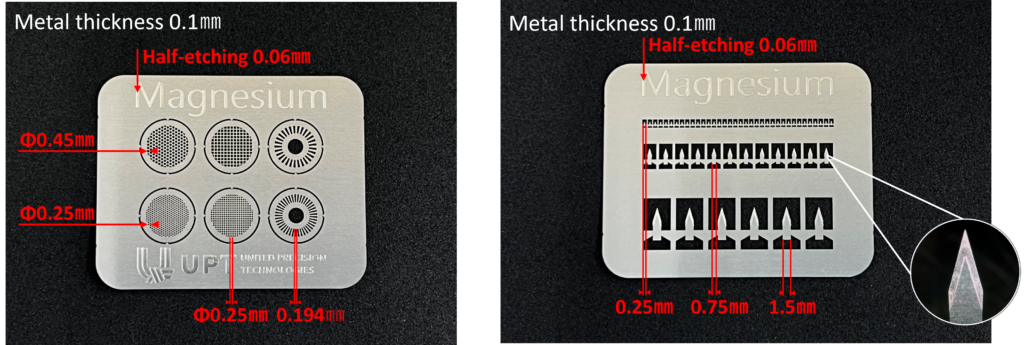

We can efficiently and accurately complete the processing of magnesium alloys, even those recognized as difficult-to-machine materials, ensuring both safety and precision.

Surface Treatment

We are capable of providing various surface treatments such as anti-reflection coating (black treatment), high corrosion resistance, low resistance (low noise), and brightening treatment.

Photo-Eching of Magnesium Alloys

Talk to Us about your Project

Since our magnesium etching products are fully customizable to fit your equipment, please don’t hesitate to reach out to us with your ideas.