Manufacturer 3D-Structured Metal Parts with

Diffusion Bonding and Photo Etching Technology

Diffusion bonding is a metal joining technique that bonds materials at the atomic level by bringing their surfaces into close contact. It enables the creation of complex 3D internal metal structures with high precision.

While adhesives and spot welding may are also used for metal joining, they techniques have drawbacks such as poor heat resistance, cleaning difficulty, and potential gaps at the joints.

Diffusion bonding, however, allows fine 3D molding with excellent dimensional accuracy and airtight bonding. It is highly reliable, maintaining product performance and shape even after long-term use under harsh conditions such as high temperatures. UPT provides a one-stop service for manufacturing metal parts using diffusion bonding—from prototyping to mass production—with short lead times.

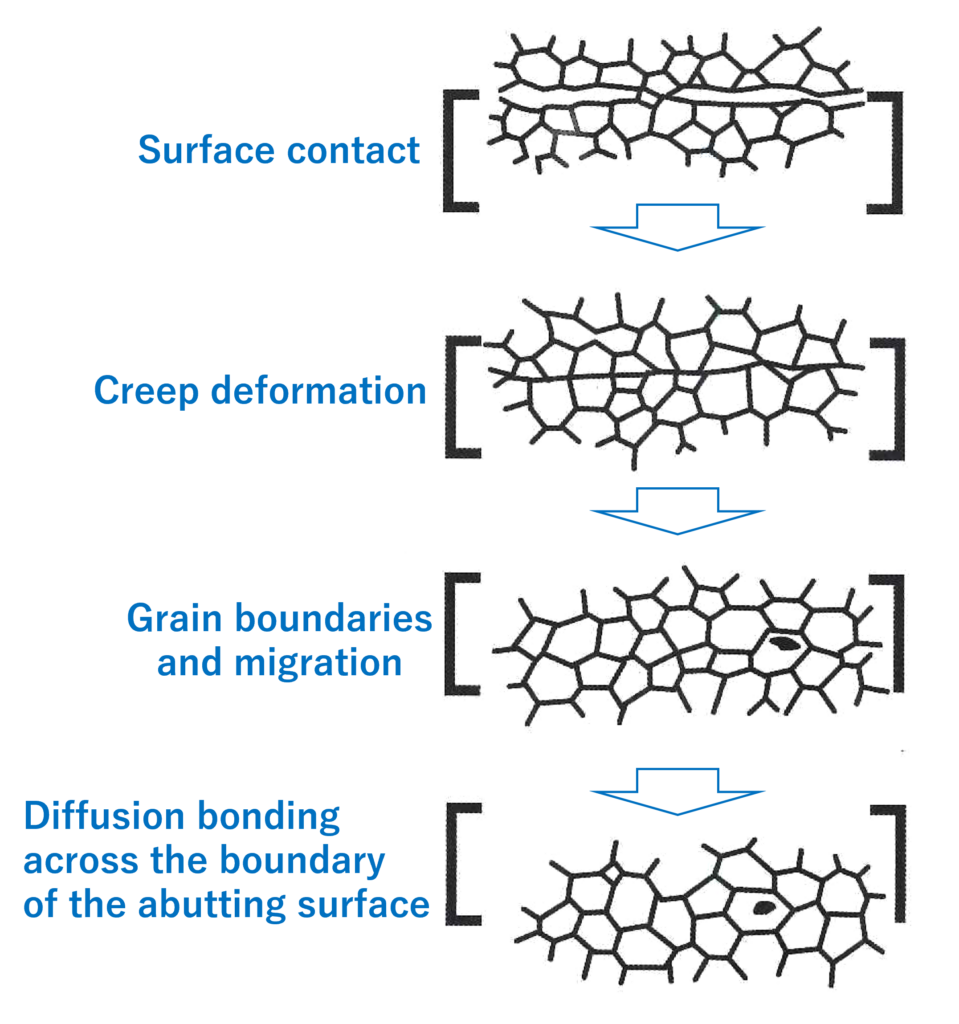

Principle of Diffusion Bonding Technology (Mechanism)

Diffusion bonding technology is a bonding technique that joins metals at the atomic level by applying heat and pressure. As a result, the metal atoms at the interface diffuse into each other, forming a strong bond.

Diffusion bonding technology is suitable for joining dissimilar metals and metals with complex shapes. It can withstand high temperatures and vacuum environments and is widely used in advanced industries such as aerospace and electronics. Additionally, diffusion bonding technology is reliable because it generates little internal stress and defects in the joint.

Benefits of Diffusion Bonding Technology

- High reliability in harsh environments (such as high and low temperature)

- High fracture toughness and high temperature resistance

- High bonding strength

- Few post-bond alignment errors

- Hermetic sealing

- High dimensional accuracy

- Little deformation

- No contamination

- Able to form 3D shapes and flow paths impossible with machining

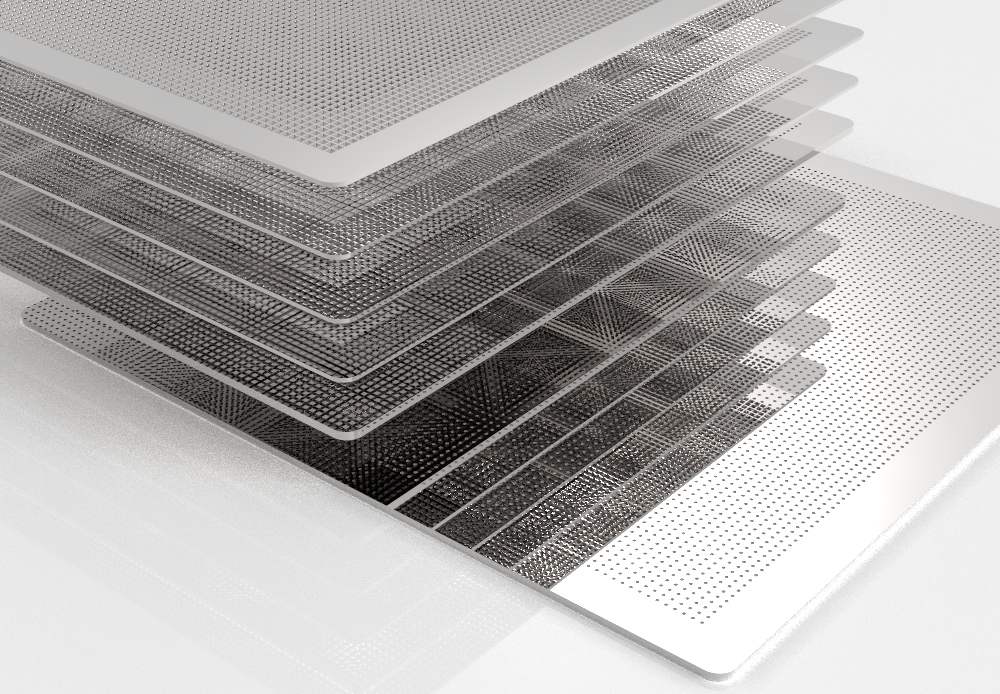

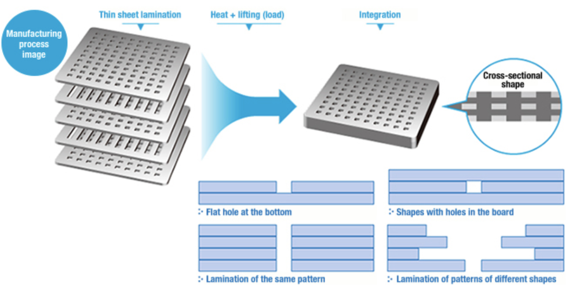

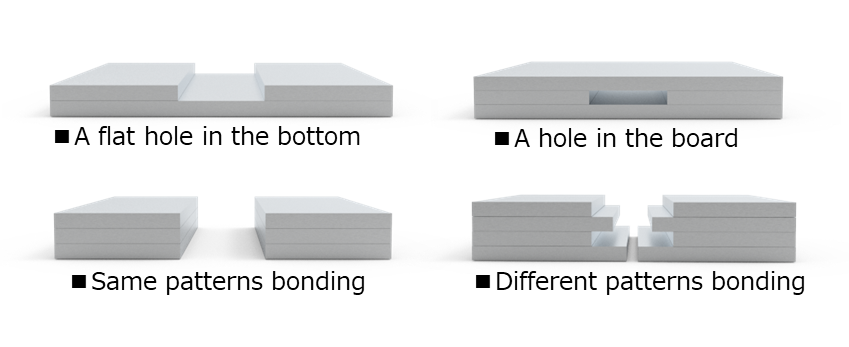

Diffusion Bonding + Photo Etching Technology

We have been creating new value through the combination of photo etching and diffusion bonding technologies. The following are examples of their use cases.

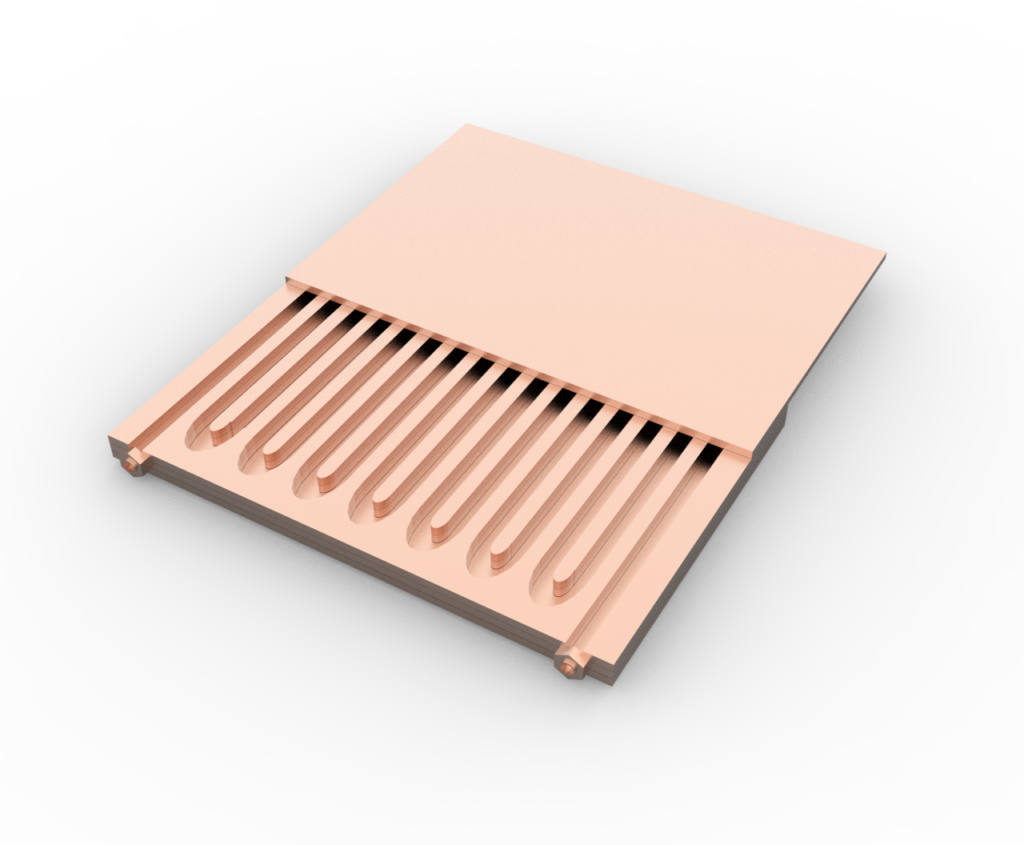

Plate thickness: 0.5 mm × 10 layers

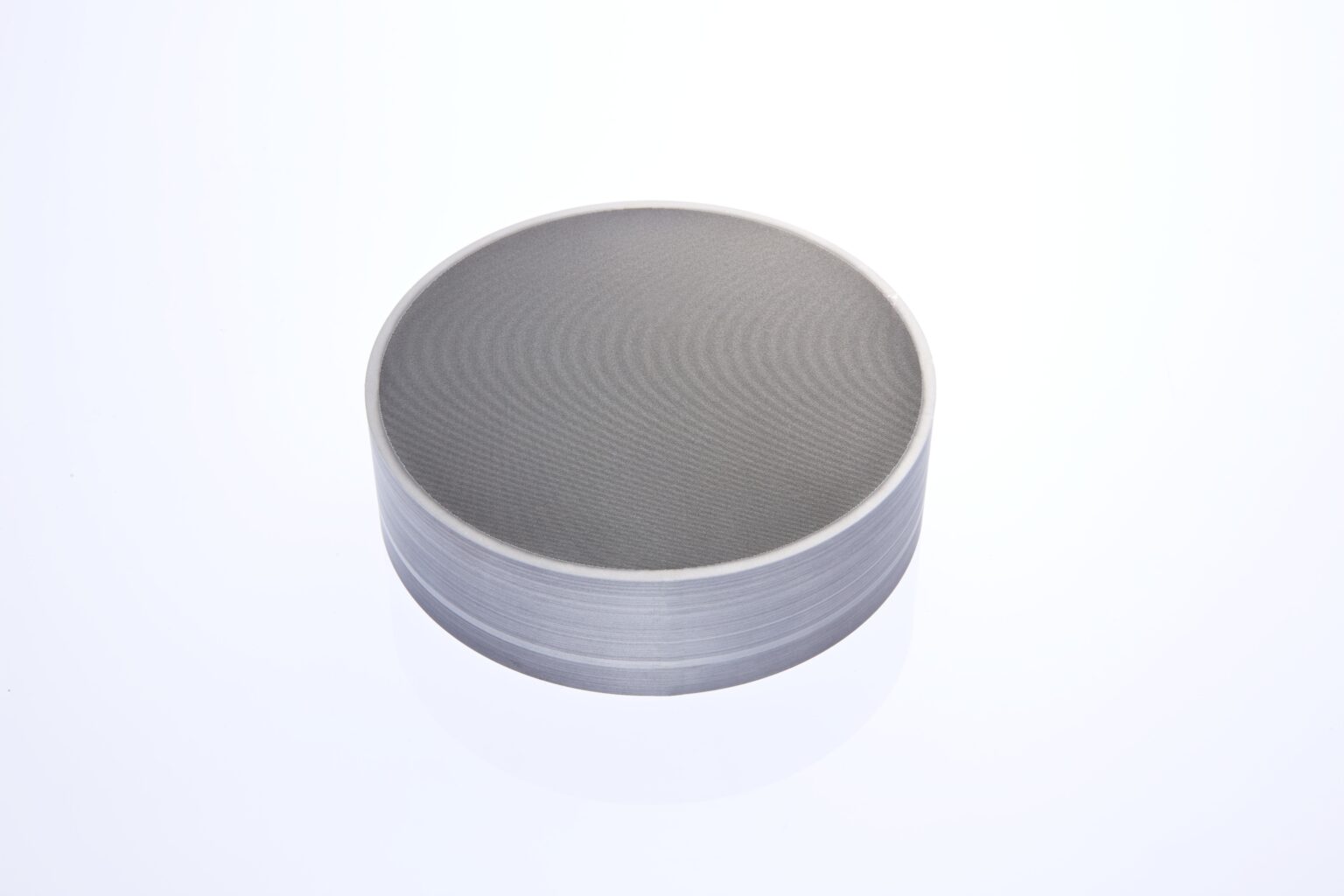

Plate thickness: 0.05 mm × 1000 layers

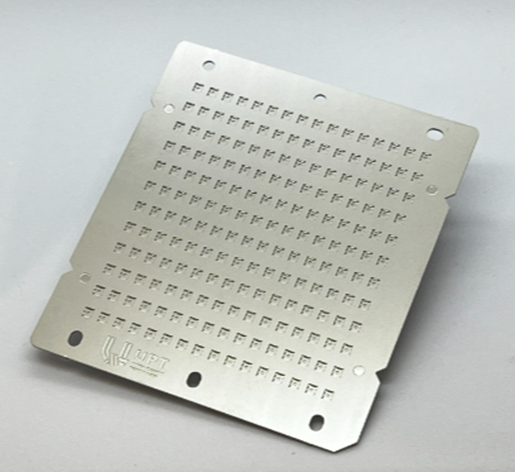

Plate thickness: 0.1 mm × 7 layers

Benefits of Diffusion Bonding + Photo Etching Technology

- Capable of handling complex and intricate designs

- High Reliability in harsh environments (such as high and low temperature)

- High fracture toughness and high temperature resistance

- Little post-bond alignment error

- High dimensional accuracy

- Little deformation

- Available to form 3D shapes and flow paths impossible with machining

- Cost-effective from prototyping to mass production

Diffusion Bonding of Materials

Stainless Steel + Stainless Steel

SUS304、SUS430、SUS316、SUS631

Nickel/Nickel Alloy + Nickel/Nickel Alloy

Ni201、36Ni、42Ni、Permalloy

Aluminum + Aluminum

A5052、A6061、A6063

Iron + Iron

SPCC

Copper/Copper Alloy + Copper/Copper Alloy

C1020、C1100

Kovar + Kovar

KV-2、KV-6

Titanium + Titanium

TR270C

Stainless Steel + Copper

Contact us for more info about bonding dissimilar metals

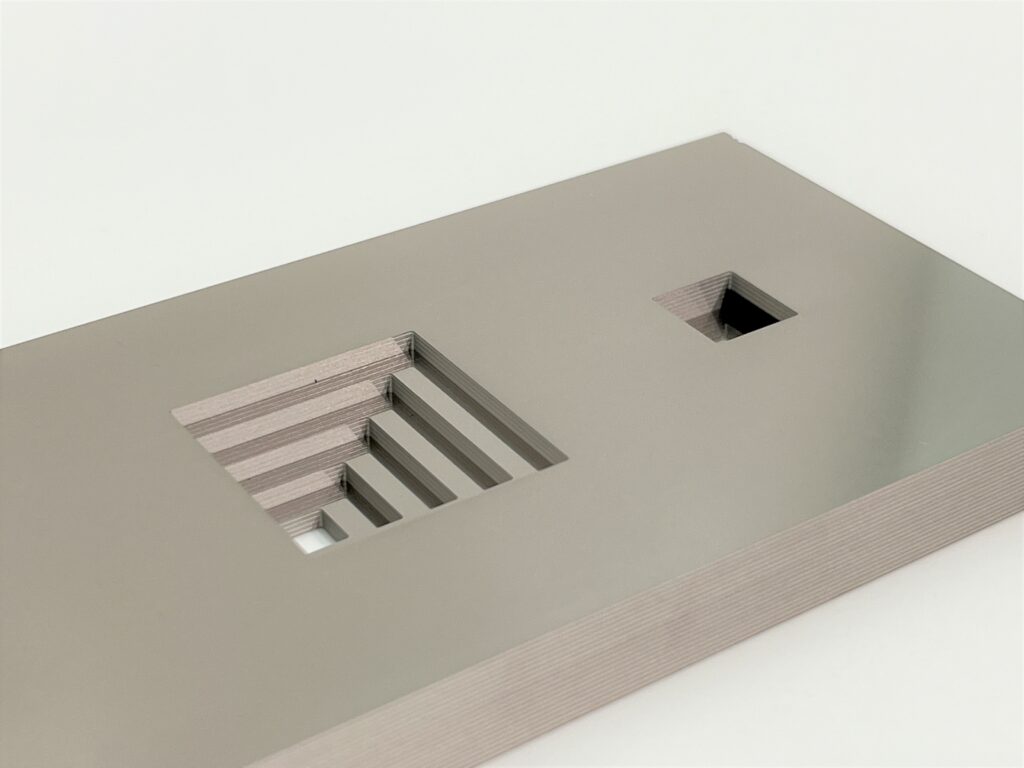

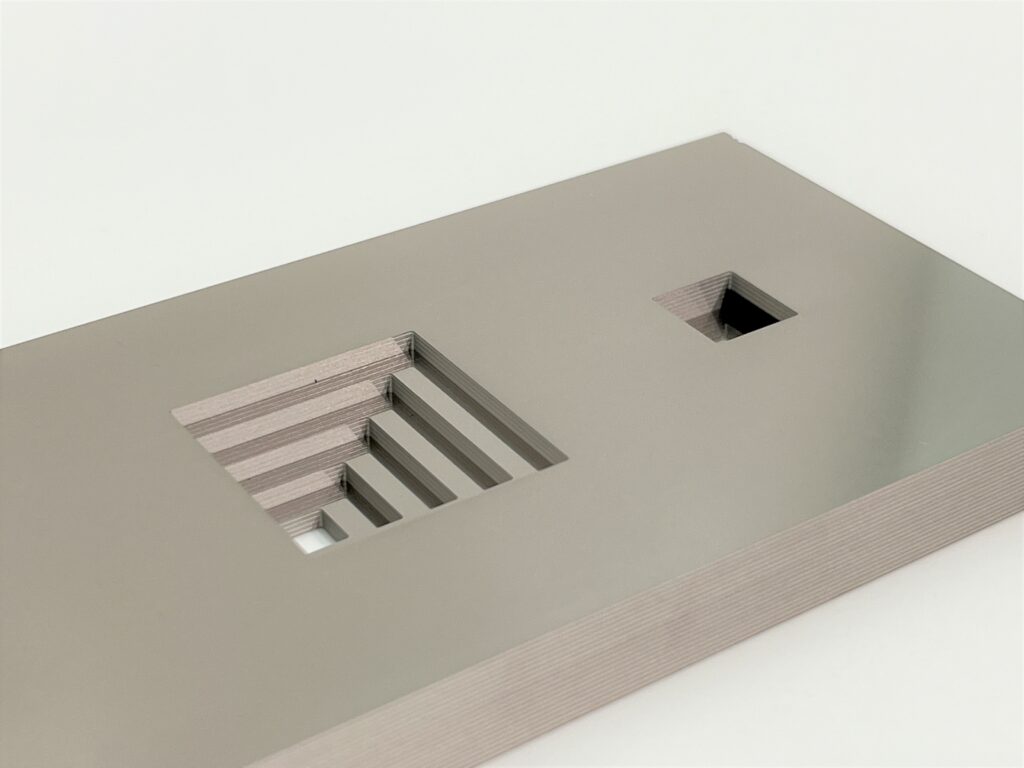

Manufacturing and Processing Image

Cross Section of Diffusion Bonded Components

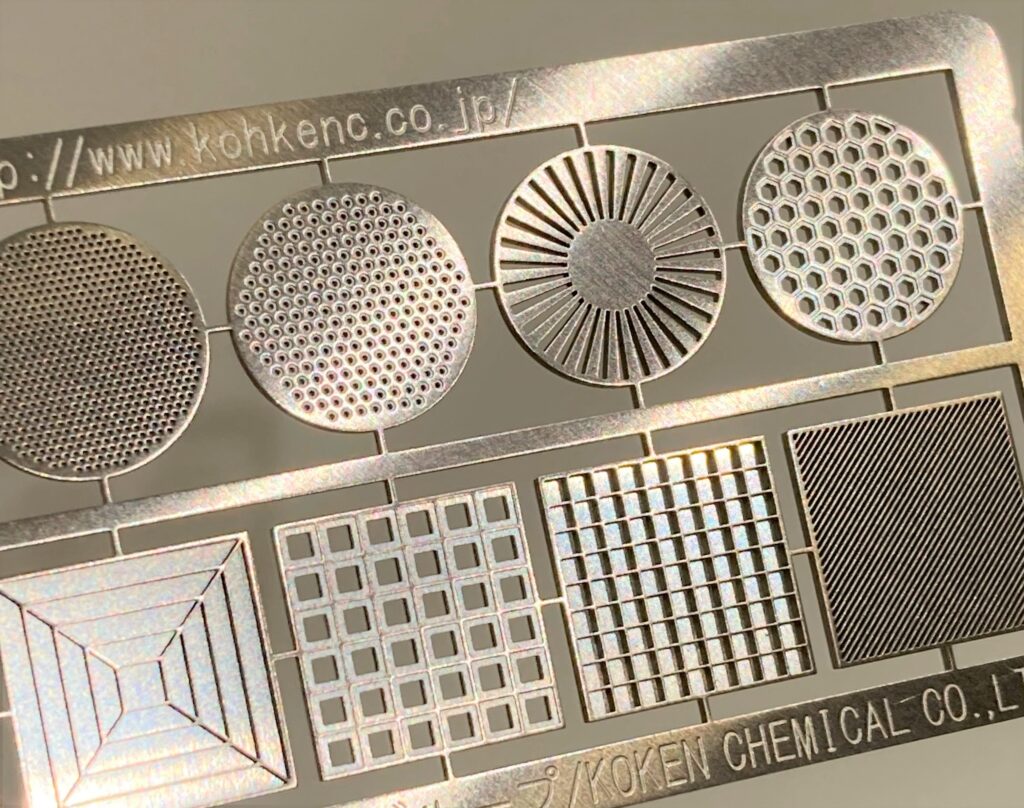

Examples of Diffusion Bonding + Photo Etching Technology

UPT offers a variety of products combine diffusion bonding and photo etching technology. Here are some examples from our products portfolio.

Cooling Plates

Cooling plates are essential cooling components for heat management in electronic equipment and semiconductor devices. Combining photo etching and diffusion bonding technology maximizes the cooling performance of these devices. We offer thermal solutions tailored to your challenges.

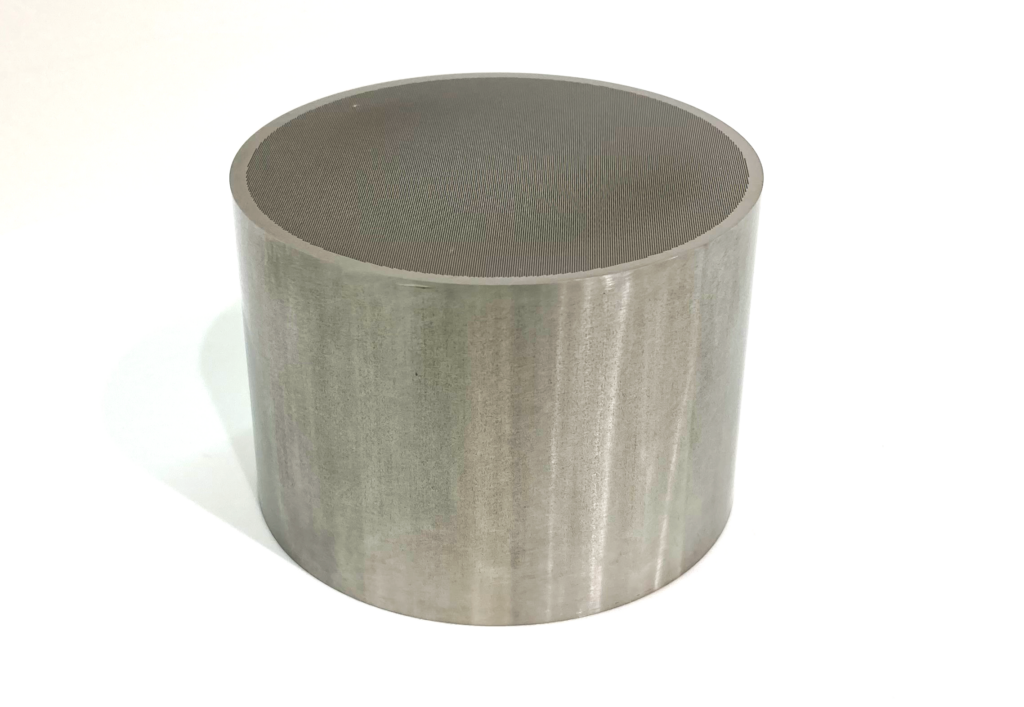

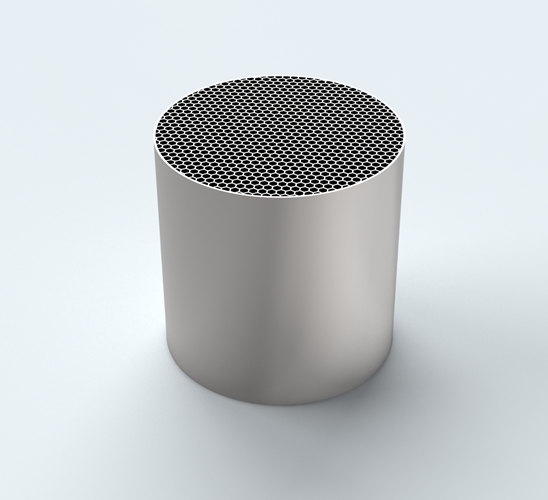

Fluid Control Bypass Mesh Filters

Thin mesh filters are integrated into precision instruments. We create high-aspect-ratio 3D mesh filters that prevent contamination. Our flat mesh filters resist dirt adhesion, have high strength, and can be used repeatedly over a long period of time. We can solve issues like misalignment during lamination (bonding), irregular hole diameters leading to unstable flow rate, pinholes, scratches, and gas burns.

Transport Trays for Electronic Components

Transport trays (jigs) are used for positioning and transporting electronic components. UPT offers precise trays and jigs by combining photo etching and diffusion bonding technology, not only allowing for stable and precise positioning of tiny electronic components, but also improving production efficiency in terms of component handling and extraction. There is no adhesive layer, which ensures products with such precise thickness.

More Manufacturing Cases

- Heat exchangers and heat sinks

- Lapping carriers

- Inkjet nozzles

- Filters

- Fuel cell separators

- Evaporation masks

- Suction plates

- Shim assemblies

- Components for electronic equipment

- Precision parts trays and jigs

FAQ

-

Which combinations of materials can UPT bond using diffusion bonding?

-

UPT’s diffusion bonding technology can join a wide range of metals, including stainless steel, copper alloys, titanium, aluminum, and nickel-based materials. It is also suitable for bonding dissimilar metals, which are often difficult to join using conventional welding. Our advanced process control enables uniform bonding even between materials with different thermal expansion coefficients.

-

How strong is the bond formed via diffusion bonding?

-

The joint strength achieved by diffusion bonding is comparable to the base metal itself, as atoms at the interface diffuse and form a continuous metallic structure. This results in high mechanical strength, excellent thermal resistance, and minimal internal defects. The process is ideal for applications that require both durability and reliability under harsh operating conditions.

-

Are there limitations in geometry or thickness when applying diffusion bonding?

-

While diffusion bonding provides excellent flexibility for complex geometries, certain factors must be considered. Typically, thicknesses from 0.1 mm to several millimeters can be processed effectively. However, very large or uneven parts may require customized tooling to ensure uniform bonding. Our engineers evaluate each design to achieve optimal bonding conditions and precision.

-

How long does the delivery take?

-

Lead time varies depending on the complexity of the part geometry and the production quantity, but UPT maintains a fast and efficient manufacturing system. For diffusion bonding only, the lead time is approximately one week, combined photo etching and diffusion bonding can be completed in about two weeks (shipment date from our factory in Japan). For more details, please feel free to contact us.

-

Can UPT perform post-processing on diffusion-bonded parts (machining, plating, finishing)?

-

Yes. UPT offers comprehensive post-processing services, including precision machining, plating, surface finishing, and inspection. By combining these processes in-house and with trusted partner networks, we deliver complete, ready-to-use products with consistent quality and reduced lead time.

-

Is there a minimum order quantity or lot size for diffusion bonding at UPT?

-

UPT is highly flexible in production volume. There is no strict minimum order quantity, and we support everything from small prototype lots to large-scale mass production. Our goal is to provide the most efficient solution for each customer’s stage—from R&D to full production—while maintaining cost-effectiveness and quality.