Smallest, Thinnest, and Finest — UPT’s Advanced Photo Etching Technology

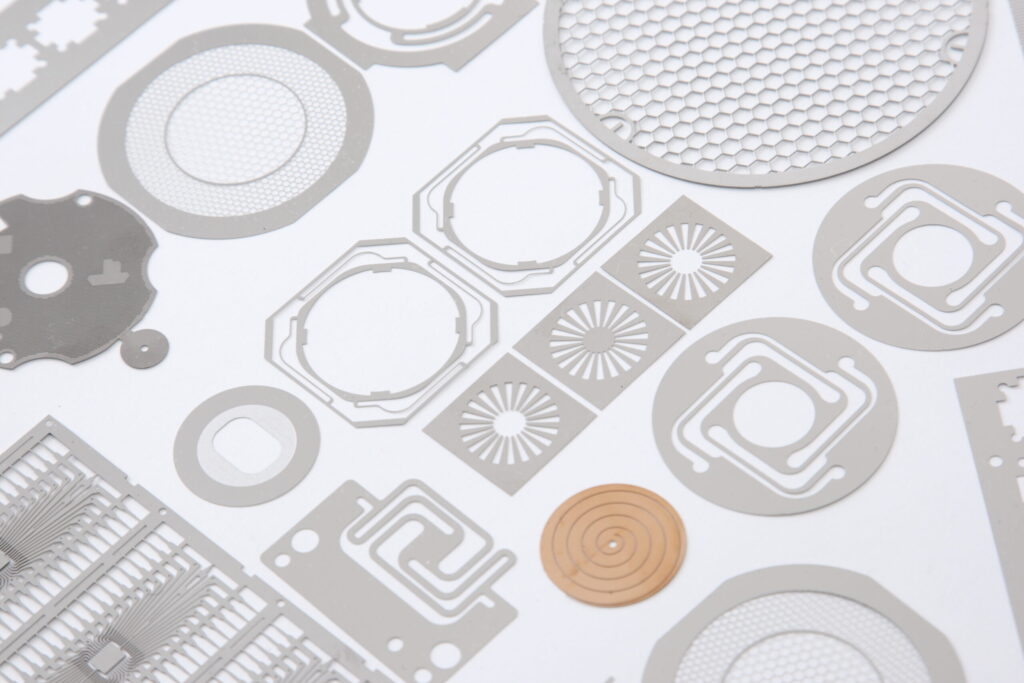

Photo etching is a precision metal processing technology that uses chemical solutions to form complex and ultra-fine patterns without applying mechanical stress. It enables the production of high-precision parts and is ideal for use in electronics, semiconductors, and other advanced industries.

UPT offers a high-precision photo etching process capable of handling various materials and thicknesses. With a proven track record and integrated production system from prototyping to mass production, UPT provides reliable, high-quality solutions with short lead times.

For photo etching processing, leave it to UPT.

What is Photo Etching Technology?

Photo etching technology is the process of using a corrosive chemical liquid to melt the specific areas on a metal sheet and forms precise, unique, and complex metal parts. This technology enables ultra-fine shaping with high precision. Metal processed products need to be highly reliable because they need to maintain their performance over long periods of use and in harsh environments.

UPT offers a one-stop solution for metal-processed parts, supporting everything from prototype samples to mass production with short lead times.

Benefits and Use Cases of Photo Etching Technology

One of the major benefits of photo etching is that it processes metal without mechanical force, minimizing the risk of material deformation or damage. In addition, high precision processing is achieved by using photoresist to etch the specific area. Also, photo etching technology can be applied to a wide range of materials, maximizing manufacturing flexibility and efficiency.

This technology is mainly used in manufacturing equipment for electronic components and semiconductors, such as jigs and small parts that require extremely fine patterns and complex designs.

Photo Etching vs. Laser Machining vs. Press Processing

There are various methods for precision metal processing, each with unique advantages and limitations. Among them, photo etching, laser machining, and press processing are widely used for fine, high-accuracy metal parts. Understanding their characteristics helps in selecting the most suitable technology for your application.

| Feature | Photo Etching | Laser Machining | Press Processing |

|---|---|---|---|

| Precision | Extremely high accuracy with no mechanical stress. | High precision, but heat may affect edges. | Accuracy depends on tooling precision. |

| Design Flexibility | Enables complex and micro patterns with ease. | Flexible, but limited for very fine holes. | Suitable for simple, repeatable shapes. |

| Material Deformation | Very low; no mechanical or thermal stress. | Medium; heat may cause slight distortion. | High; mechanical force can deform material. |

| Thickness Range | 0.004mm–2mm | 0.05mm–3mm | 0.1mm–10mm |

| Tooling Cost | Low, as no metal mold is required. | Medium, as no mold is required, but the equipment cost is higher. | High, requires precision molds. |

| Production Speed | Moderate; suitable from prototyping to mass production. | Fast for small lots, slower for large volumes. | Fast and efficient for mass production. |

What is UPT’s Photo Etching Technology?

Smallest, Thinnest, and Finest

UPT has a proven track record of achieving top market share for high precision metal components used in smartphones. Our technology can process hard-to-machine materials of various thicknesses, ranging from 0.004 mm to 2 mm. UPT can support you as a partner across all applications, driving technological innovation together.

We constantly research new technologies to improve product performance, reduce costs, and enhance customer satisfaction and market adaptability.

High Quality, Low Cost, and Short Lead Times

We have implemented the equipment and quality control systems developed in our Japanese factories at a facility in Thailand, enabling low-cost mass production with high quality. We have a wide range of materials, with over 500 types always in stock, and a dedicated prototyping team to ensure quick responses and short lead times.

UPT’s Reliable Response (One-Stop Solution)

UPT provides a one-stop solution for various customer processing requirements, from design to manufacturing, plating, and machining. By coordinating and managing external third-party suppliers, we help our customers improve production efficiency. In addition, we operate mass production facilities in Japan and Thailand and offer support in multiple languages, including Japanese, English, Chinese, Korean, and Thai.

Processable Materials

Stainless

SUS301, SUS304, SUS430, SUS316, SUS631

Nickel silver

Ni201, 36Ni, 42Ni, Permalloy

Steel

SPCC

Titanium

TR270C

Aluminum

A1050, A1100, A5052, A6061, A6063

Copper/Copper alloy

C1020, C1100, C1720, C2680, C2801, C5191, C5210, C7521, C7701

Kovar

KV-2, KV-6

Carbon steel

SK5

Applications of Photo Etching Technology

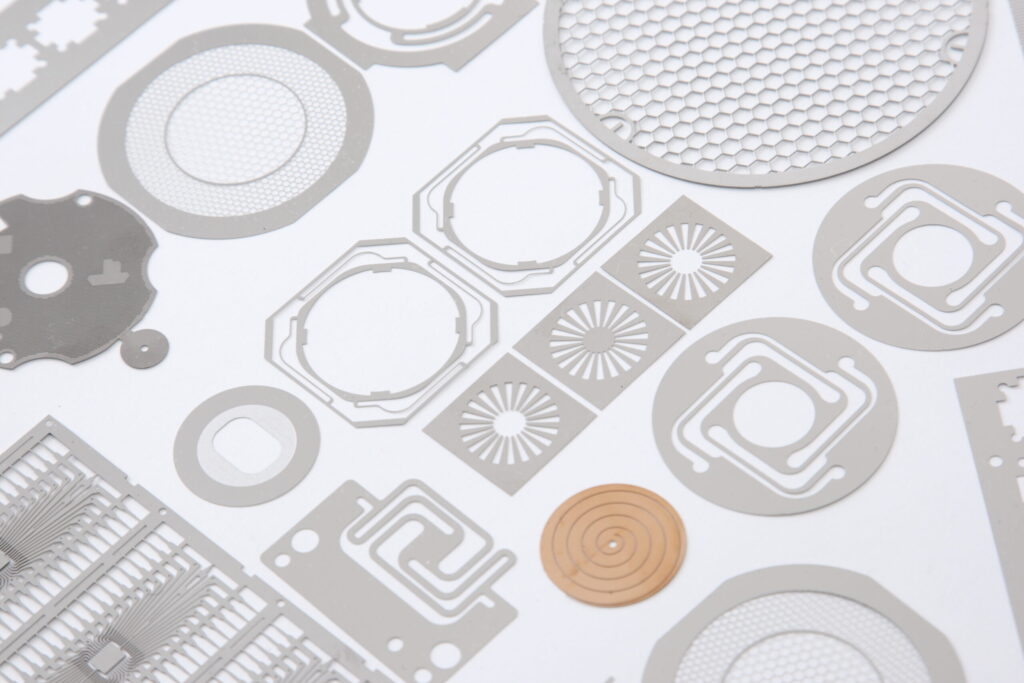

Semiconductor Test Solutions

Photo etching technology enables the processing of metals with excellent conductivity and durability with high dimensional accuracy. This strength is suitable for manufacturing probe pins and test sockets, which are key components in semiconductor test equipment. UPT offers the Union Contact® (one-piece probe pin) and Micro Metal Socket® (test socket).

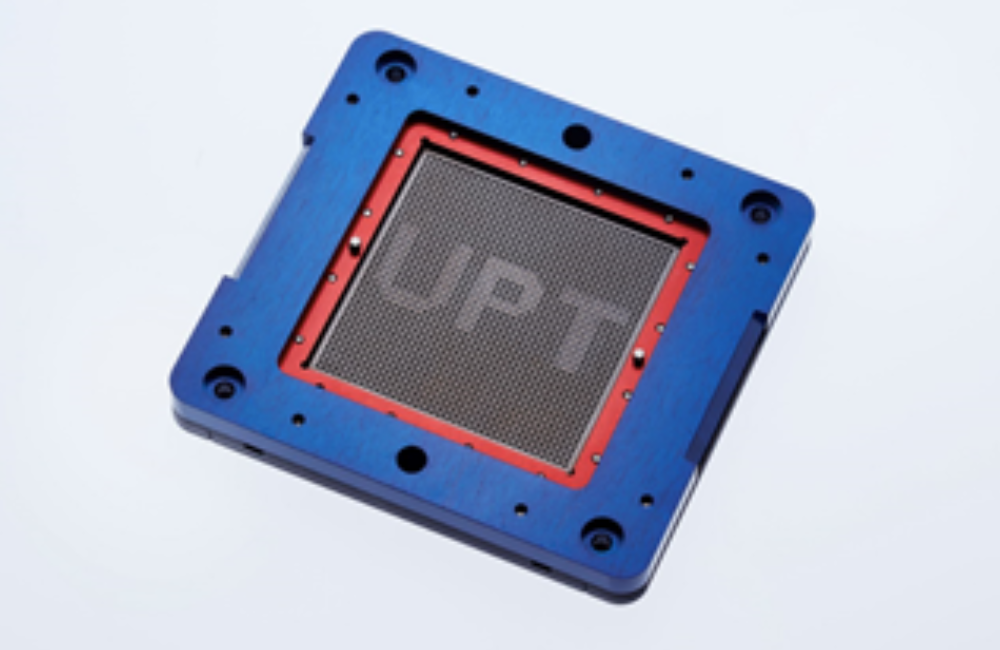

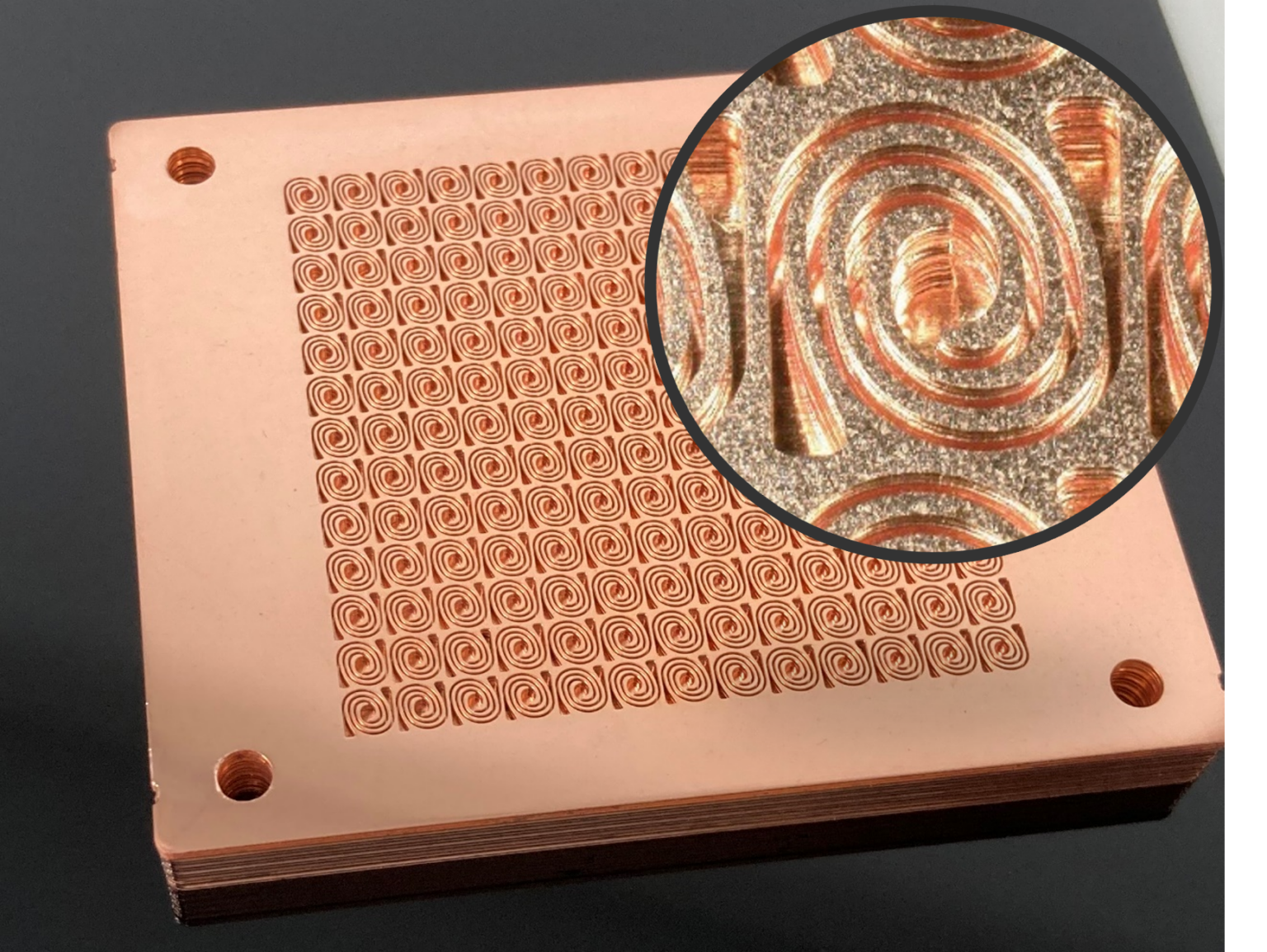

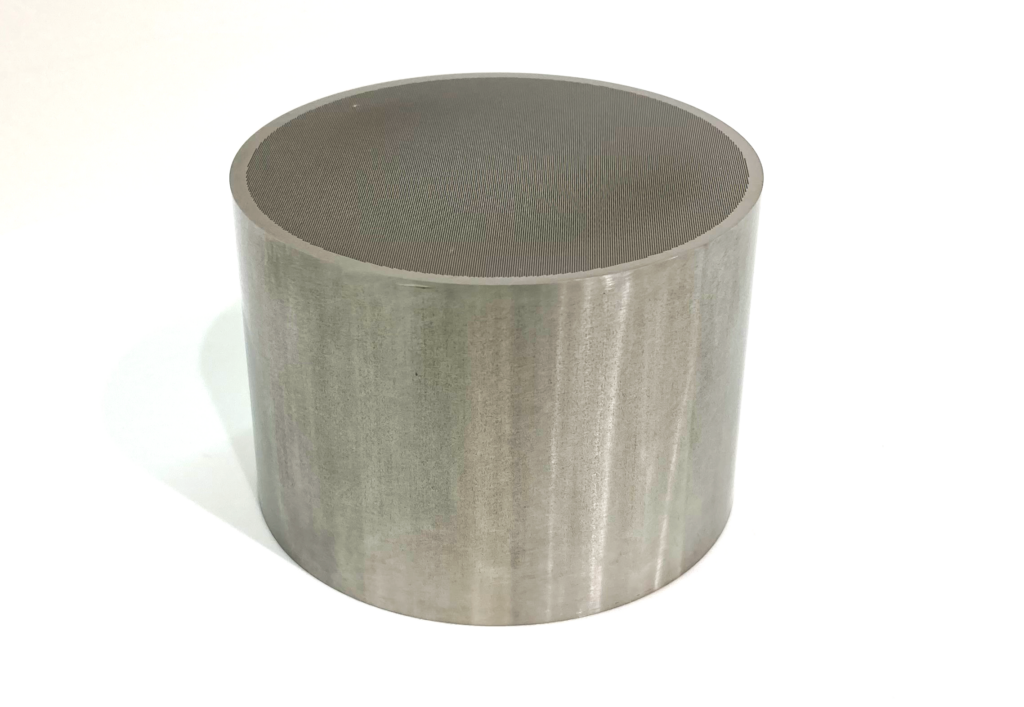

Thermal Solutions

Photo etching technology has excellent capability for forming very fine flow paths used in thermal solutions such as cold/cooling plates and heat sinks. This technology is suitable for applications that require high cooling performance to process complex patterns with high precision in metal sheets which have a high thermal conductivity. We offer thermal solutions for various types of cold/cooling plates and heat sinks.

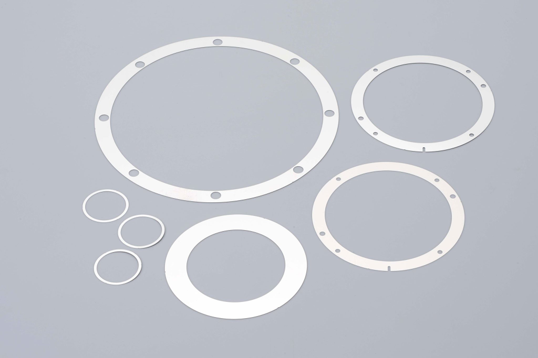

Shims

Photo etching technology can process metal foils/plates and sheets with high precision, and it is an ideal solution for manufacturing gap adjustment components such as shim spacers. This technology allows for consistent production of exact thickness and shape even with ultra-thin materials, making it valuable for applications requiring high accuracy.

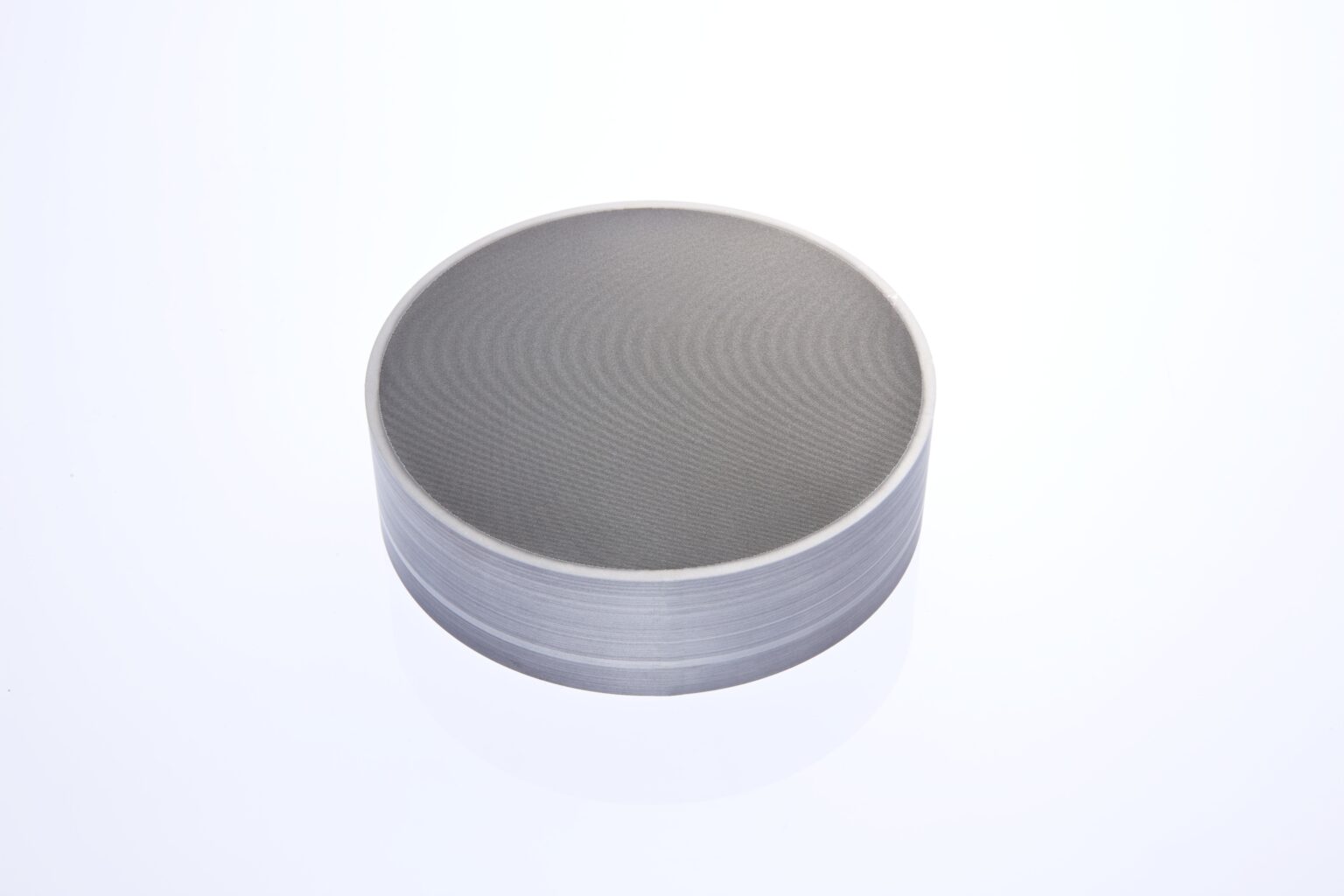

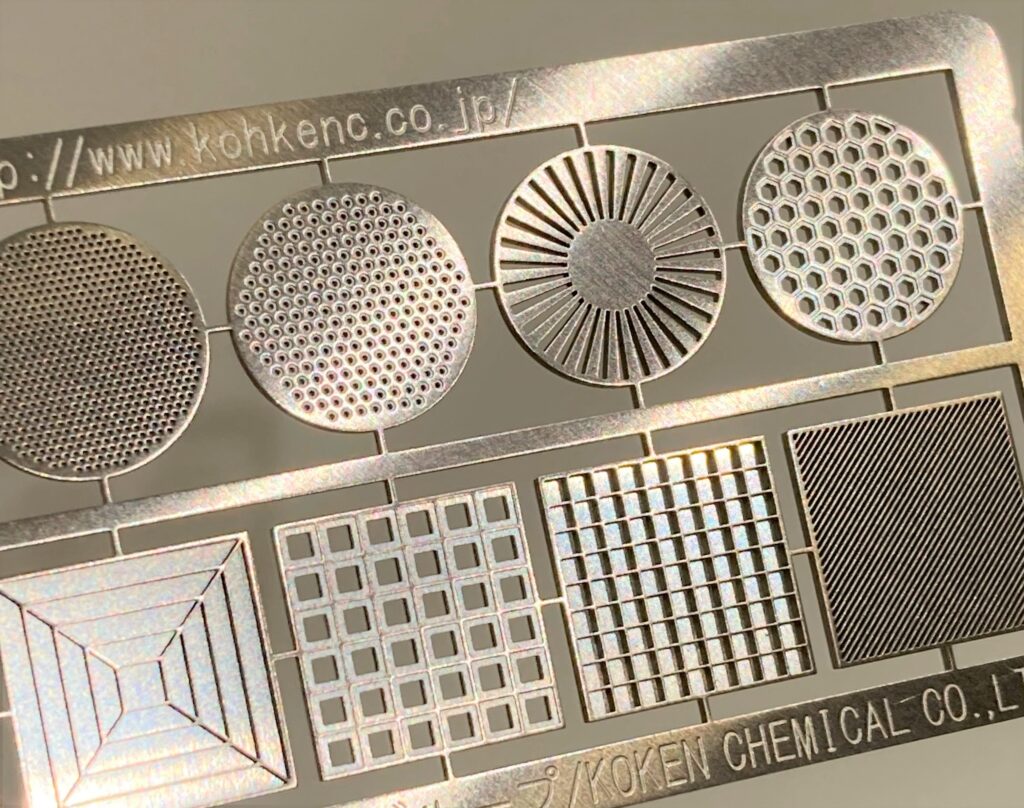

High-Precision Filters

Photo etching is suitable for manufacturing high-precision filters that can remove fine impurities from liquids and gases or perform precise flow control. It can precisely process fine holes and complex patterns.

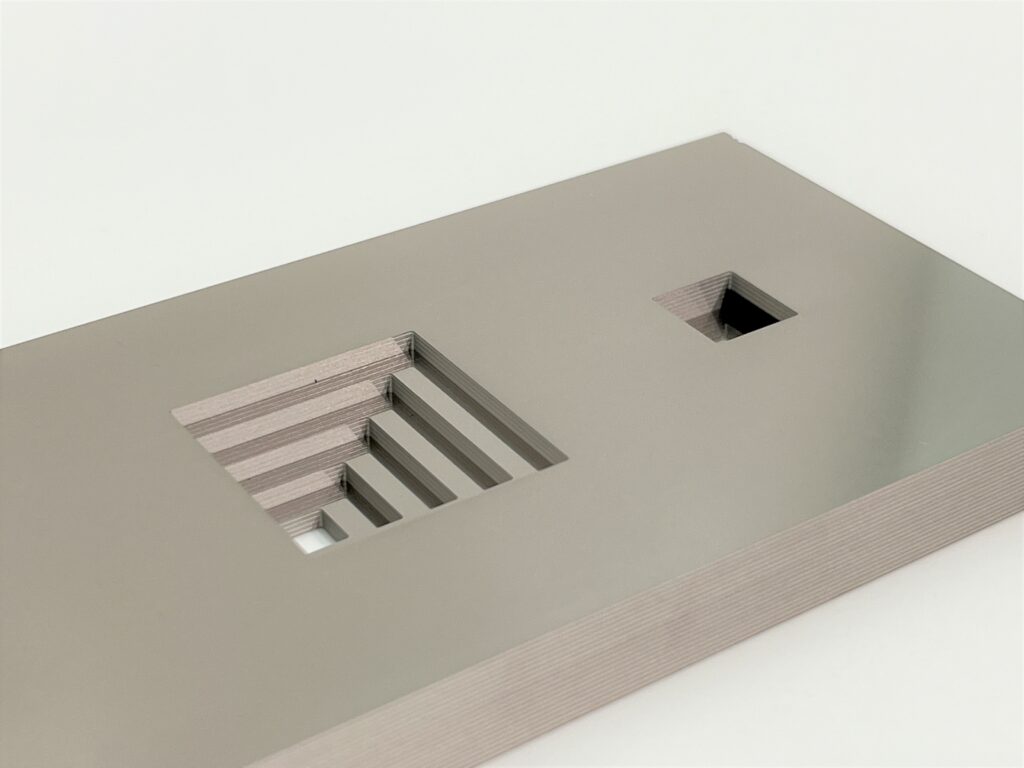

Diffusion Bonding + Photo Etching Technology

We have been creating new value through the combination of photo etching and diffusion bonding technologies. The following are examples of their use cases.

Plate thickness: 0.5 mm × 10 layers

Plate thickness: 0.05 mm × 1000 layers

Plate thickness: 0.1 mm × 7 layers

Benefits of Diffusion Bonding + Photo Etching Technology

- Capable of handling complex and intricate designs

- High Reliability in harsh environments (such as high and low temperature)

- High fracture toughness and high temperature resistance

- Little post-bond alignment error

- High dimensional accuracy

- Little deformation

- Available to form 3D shapes and flow paths impossible with machining

- Cost-effective from prototyping to mass production

FAQ

-

What materials and thicknesses can UPT process using photo etching?

-

UPT can process a wide range of metals, including stainless steel, copper alloys, nickel silver, titanium, and aluminum. The process accommodates sheet thicknesses starting from ultra-thin foils as thin as 0.004 mm. Thanks to our advanced equipment and specialized expertise, we are able to achieve stable and precise processing while maintaining high dimensional accuracy across different materials and thickness ranges.

- How precise is UPT’s photo etching in terms of tolerances or line widths?

-

UPT’s photo etching achieves high precision with tolerances as tight as ±5 μm, depending on material and thickness. Line widths and hole diameters of 20 μm or smaller can be realized. The non-contact chemical process eliminates stress and deformation, ensuring excellent reproducibility and accuracy, even for complex designs.

-

Are there limitations or constraints (e.g., aspect ratio, minimum hole size) in photo etching?

-

Photo etching allows for highly flexible design possibilities; however, certain limitations arise depending on the type and thickness of the material. Hole diameters can be processed at D = t or greater, and no smaller than 0.05 mm. For shapes with very deep or narrow aspect ratios, design optimization may be required. Our engineering team provides full support to ensure optimal manufacturability for each design.

- How long is the delivery time?

-

Delivery time varies depending on the design complexity and quantity, but UPT is known for its quick turnaround and flexible scheduling. Prototype etching products can be delivered in as little as two days (shipment date from our factory in Japan or Thailand). Please feel free to contact us for more details.

-

Can UPT handle post-processing steps such as plating, machining, or assembly?

-

Yes. UPT offers a one-stop solution that covers the entire production process — including design, photo etching, plating, precision machining, surface treatment, and assembly. By managing both in-house and partner processes, we ensure consistent quality and reduced lead times for our customers.

-

Is there a minimum order quantity (MOQ) or lot size at UPT?

-

UPT is highly flexible and supports orders from small prototype quantities to full-scale mass production. There is no strict minimum order requirement. We work closely with customers to match their project stage — from R&D samples to long-term volume supply — ensuring optimal cost efficiency and delivery performance.