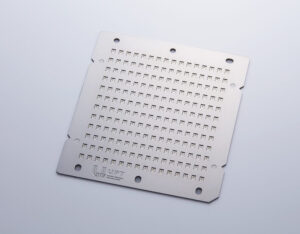

Improve Production Process with Half-Etching Technology

The photo-etching technology is used to cut/process metals by utilizing the chemical reaction precisely.

The half-etching technology involves melting half the thickness of the plate. The Laser/Cutting technology is required multiple processes, but the half-etching technology is required just a single process.

UPT’s half-etching technology is capable of melting up to 80% of the plate thickness.

Examples of use case are the decorative items that add shading to metal and stepped flow products.

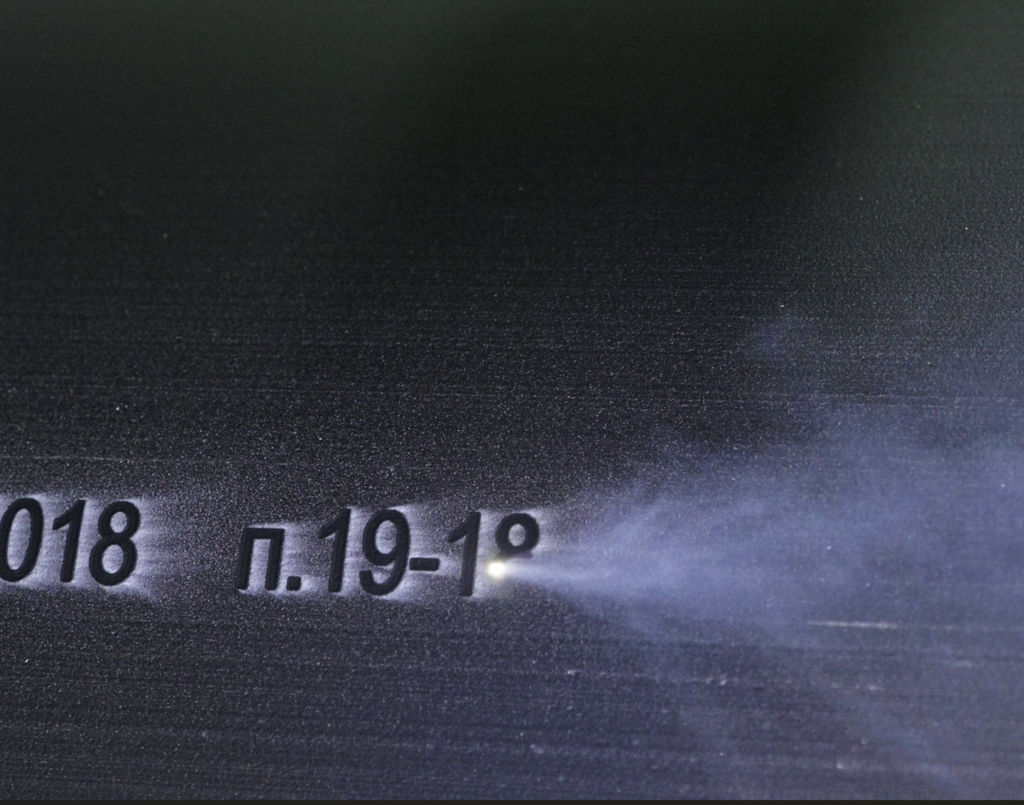

Challenges of Laser Marking

①Multiple process controls are required.

The marking quality is not alwas good, because this technology leads to thermal stress occurring at the cutting edge.

②The entire laser marking process takes longer,and the final products have burrs. Additionally, the running costs are expensive.

Challenges of The Stamping Technology

The stamping Technology is not suitable for high volume mass production, and the lead time is longer.

UPT Offers the Half-Etcihng Technology

Advantages

Only one process is required, anabling short lead time.

High quality is ensured because the half-etching process is a single process.

Low cost.

We also have diffusion bonding technology, which allows the fabrication of cavity flows such as channels by overlapping half-etched metal plates using diffusion bonding technology.

Half-Etching Specifications

| Metal Type | All etchable metals (Excluding tungsten-based, gold and silver) |

| Metal Thickness | Available any depth 0.02mm(Copper metals 0.05mm) Up to 80% of board thickness |

| Additional Cost | It can be done in one production run, so no additional cost is required. |

VALUE①

Single Process

In a single process, complex designs can be created on metal sheets.

VALUE②

High Quality

The Half-Etching process is single method, requiring no additional process that would impact the quality.

VALUE③

Low Cost

The Half-Etching technology is cost-effective becasue it involves a single process, eliminating the need for additional steps.