Fighting Against The Heat

The higher thermal densities is now getting critical issue because of a recent advances in high-density mounting in conjunction with faster processing speeds in electronic equipment and smaller equipment designs.

Also, one of the challenges now facing electronics manufacturers is the how to make heat dissipation path/area due to the increasing restrictions imposed by design when designing electronic devices.

In addition, the thermal resistance of semiconductor chips is getting increase because of integration more circuits in one package, high current consumption, and smaller package.

The electronic equipment is a battle against heat.

The optimizing heat dissipation and cooling solutions is important challenge for all the engineer who develop the precision equipment.

Selection of Cooling Solutions

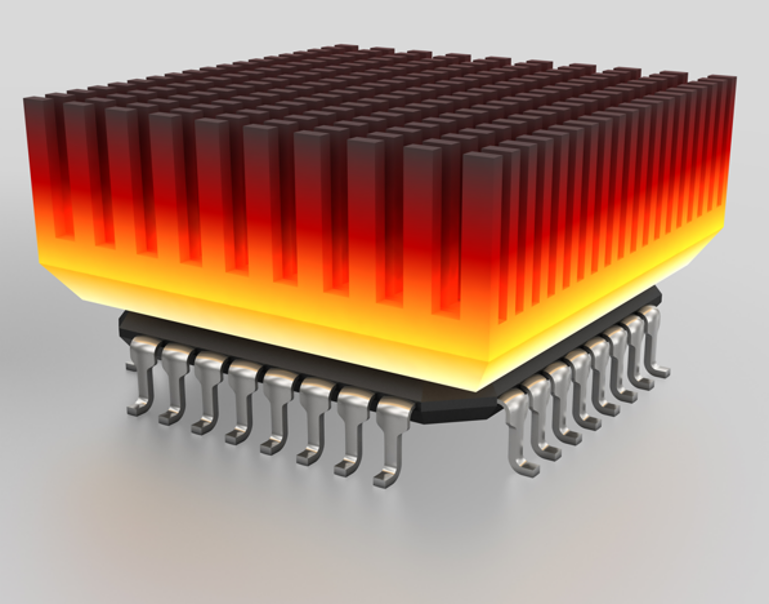

Heat Sinks

The heat sinks are mainly made of metals, such as aluminum, iron, and copper, which have good heat dissipation characteristics. The surface area is formed in the shape of a thorn surface or bellows with plates or rods called fins to improve heat dissipation performance. The cooling performance can be improved by attaching a fan to the heat sink. This is low cost method, but the size would be bigger.

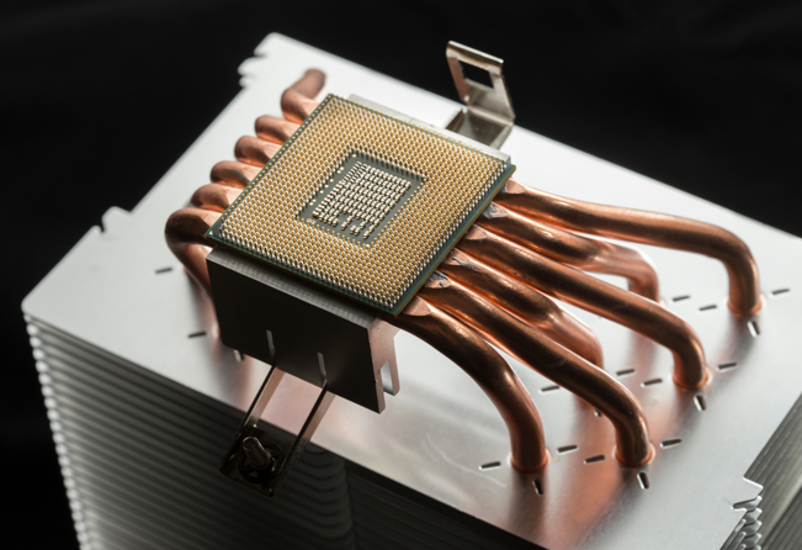

Heat Pipes

It is one of the technologies and mechanisms to improve heat dissipation efficiency. A volatility liquid is enclosed in a metal pipe made by high thermal conductivity. The mechanism is to make a cycle of evaporation and condensation of volatility liquid in pipe by heating one side of the pipes and cooling the other side.

Vapor Chamber

The volatility liquid is enclosed in the heat sink.

The heat from the heat source vaporizes the volatility liquid, and the vapor moves through that space, and when it reaches the heat sink side, the heat is released and returns to the liquid. The principle is roughly the same as that of heat pipes. The vapor chamber is smallest solution, however it would be expensive.

Proposal

UPT offers the Union Cooling Tech® with micro-channels for the equipment which is required the high heat dissipation with small precision equipment.

Advantage

- Custom designs are available.

- High quality products based on our advanced manufacturing capability.

- Leak detection inspection before shipment.

- We can also manufacture products that require multiple processes through our external company partners.

What is the Microchannel?

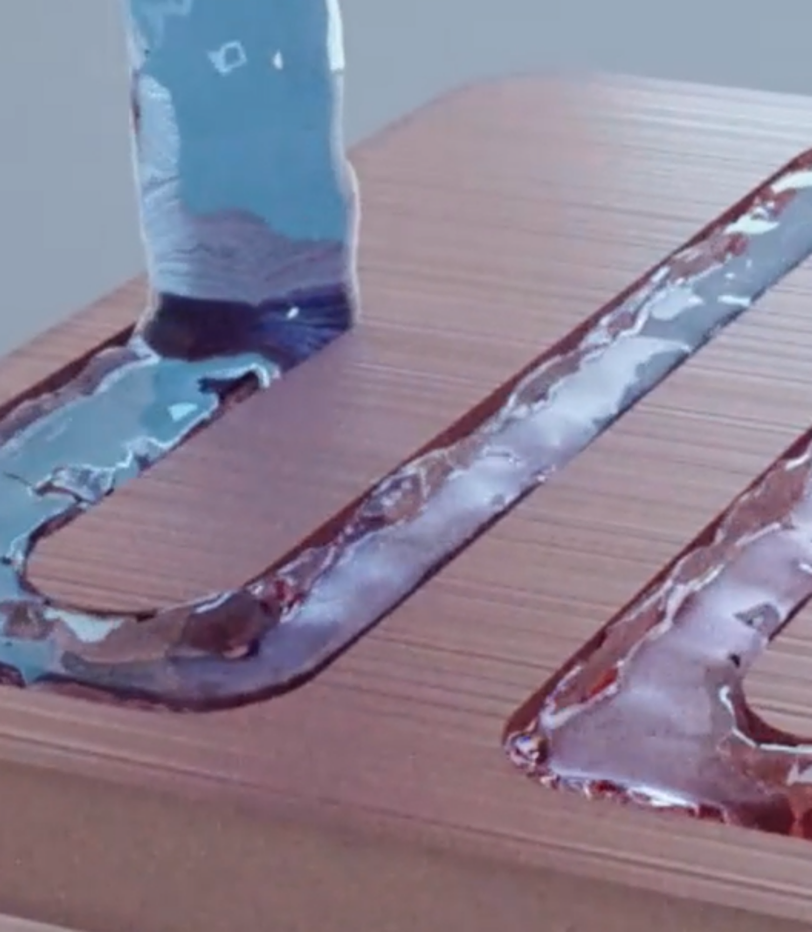

The Microchannels are air or liquid flow paths fabricated using microfabrication technology, and are generally defined as those with a diameter of a few millimeters or less.

This is a particularly promising solution for heat dissipation and miniaturization of precision machinery. The scale effect and improved heat dissipation performance of microchannel technology are expected to dramatically reduce the size and performance of heat exchangers.

Microchannel Technology

It is generally known that the heat transfer coefficient in a heat exchanger tube is inversely proportional to the cross-sectional dimension of the flow path of the tube. In other words, the thinner channel tube makes the higher the heat exchange rate. Furthermore, if the fluid in the channel flows at a high velocity, the heat exchange rate through the channel’s tube wall can be expected to increase. However, since flow resistance increases with decreasing tube diameter, there is a trade-off between heat transfer and pressure drop, and optimizing these factors is an important aspect of microchannel design.

Structure of Union Cooling Tech®

Value①

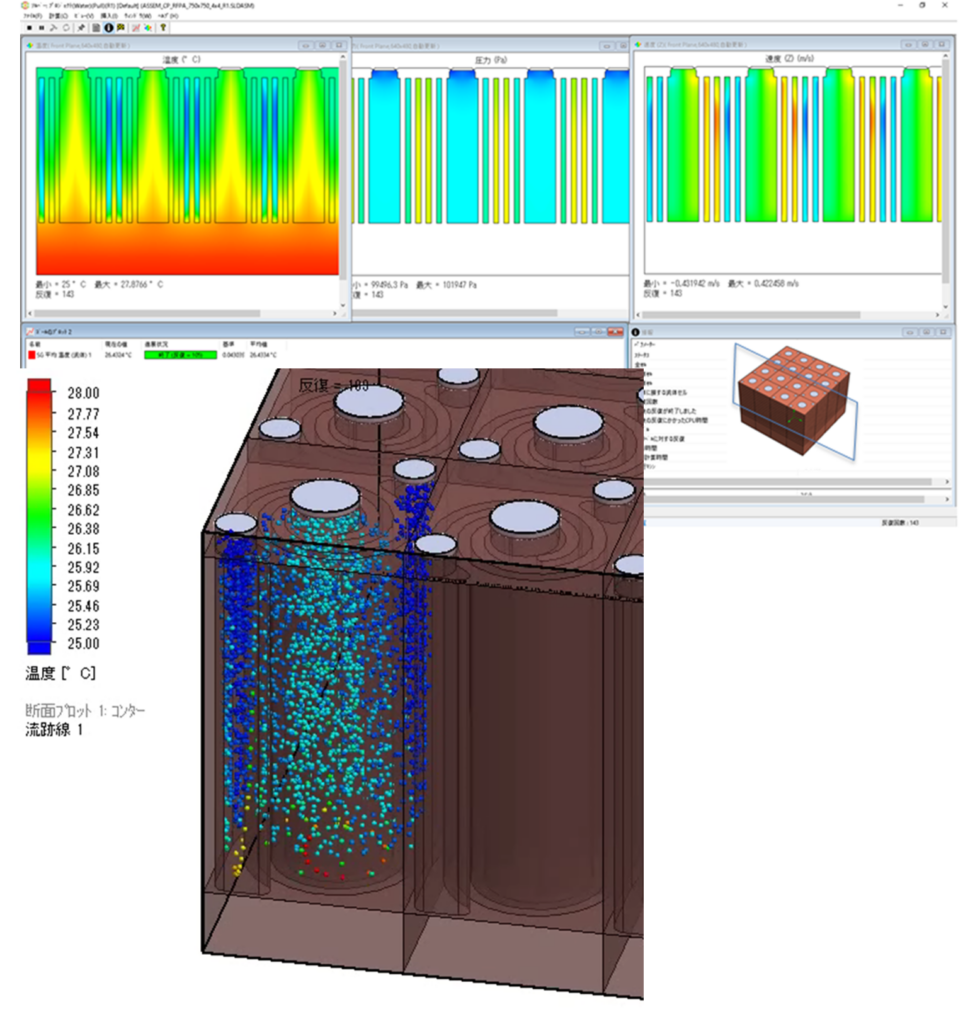

Supports the thermal analysis simulation for optimal microchannel design.

UPT supports the simulation, such as pressure distribution, flow velocity, and heat removal characteristics of internal channels of Union Cooling Tech®, and help for designers for development.

Value②

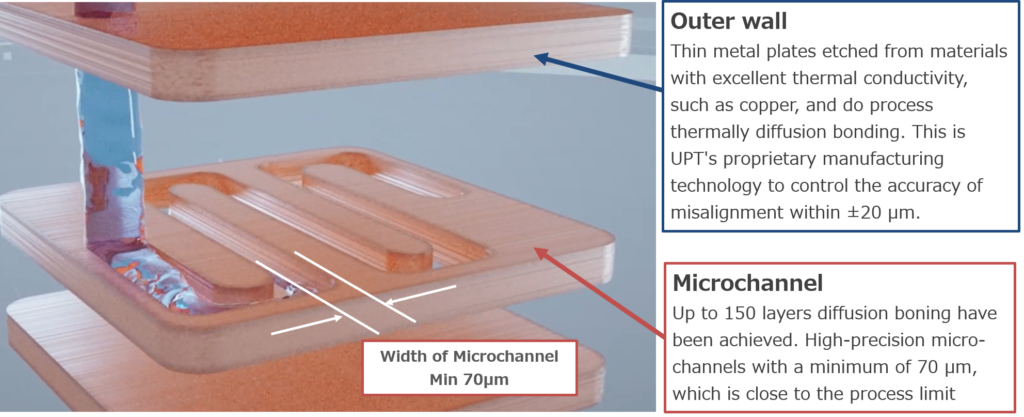

High quality products by precision etching technology and bonding.

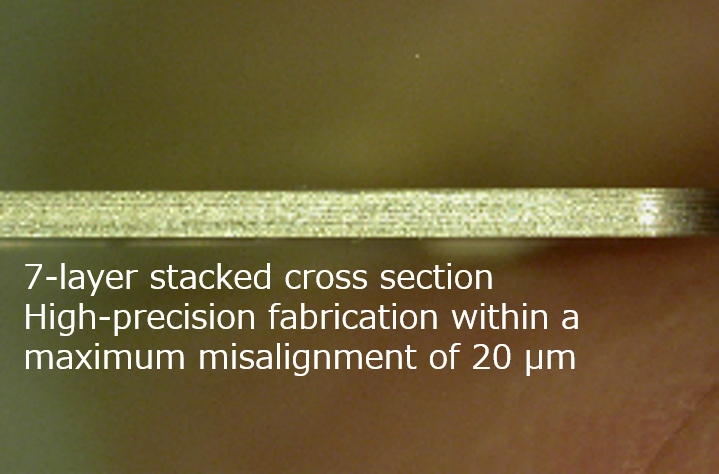

The etching accuracy is less than 10% of metal thickness by UPT unique know-how, and the misalignment of stacking metal plate is Max 20um. And ship the products after leak-test.

Value③

One-stop ordering for complex processed products.

Not only diffusion bonding of laminating thin foil metal sheets produced by the etching technology, but also additional processing is available, such as drilling and plating after diffusion by using our network of partner companies.

Union Cooling Tech® Specifications

| Specification | |

|---|---|

| Metal type | Copper |

| Metal thickness | 50μm~ |

| Processing accuracy | Etching process accuracy: ±10% (relative to metal thickness) Stacking misalignment processing accuracy: ±20μm |

| Surface treatment | Plating such as nickel works as a surface treatment after bonding |

| Amount of leakage | Leak Detectors check the amount of product leakage |