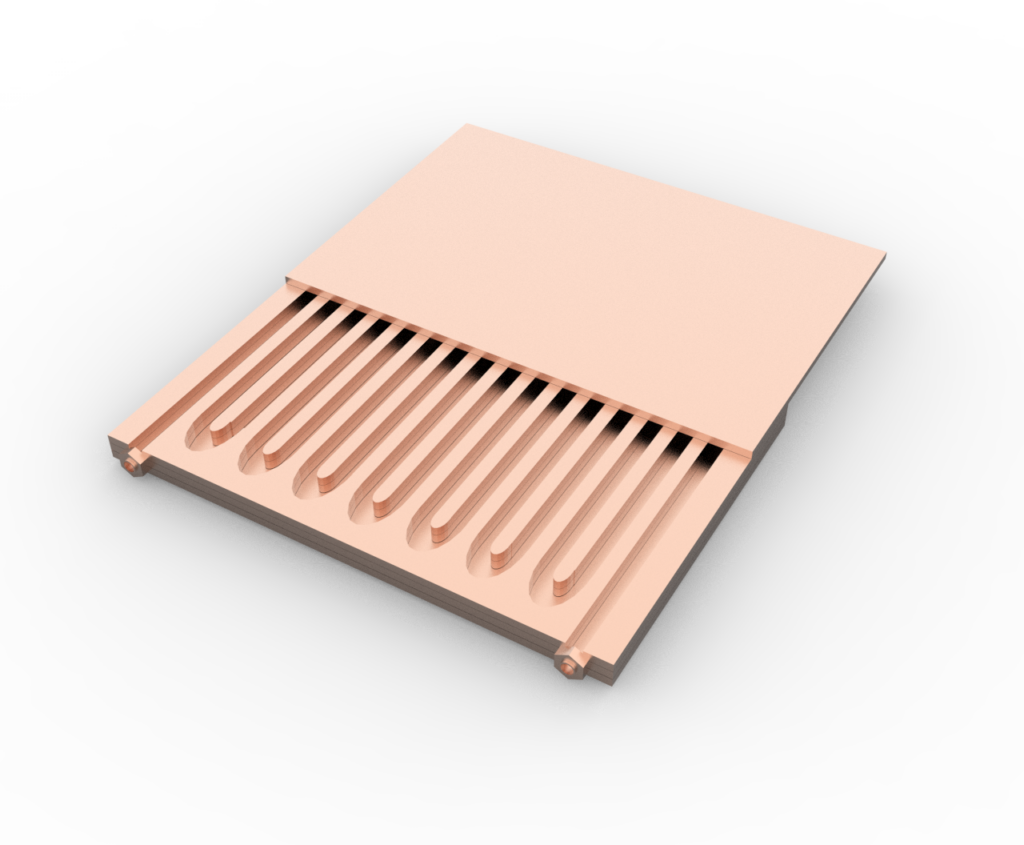

Liquid-Cooled Heat Sinks with Flexible Flow Path Design with Photo Etching and Diffusion Bonding Technology

Liquid-cooled heat sinks efficiently remove heat from high-performance components (CPU, GPU, ASIC etc.) in electronic devices and computers. UPT offers high cooling performance heat sinks with a combination of photo etching and diffusion bonding technology.

What is Liquid-Cooled Heat Sink?

A liquid-cooled heat sink is cooling device designed to efficiently remove heat from high-performance components (CPU, GPU, ASIC etc.) in electronic devices and computers. It uses a liquid coolant to maintain low temperatures of the components. A heat sink body is mainly made of copper or aluminum, a coolant to absorb heat, a pump to circulate the coolant, a radiator

to release heat, and tubes to facilitate circulation. It offers highly efficient cooling and is particularly suitable for high-performance electronic devices.

UPT’s Core Technologies Used in Liquid-Cooled Heat Sinks

UPT designs liquid-cooled heat sinks by combining key technologies, photo etching and diffusion bonding.

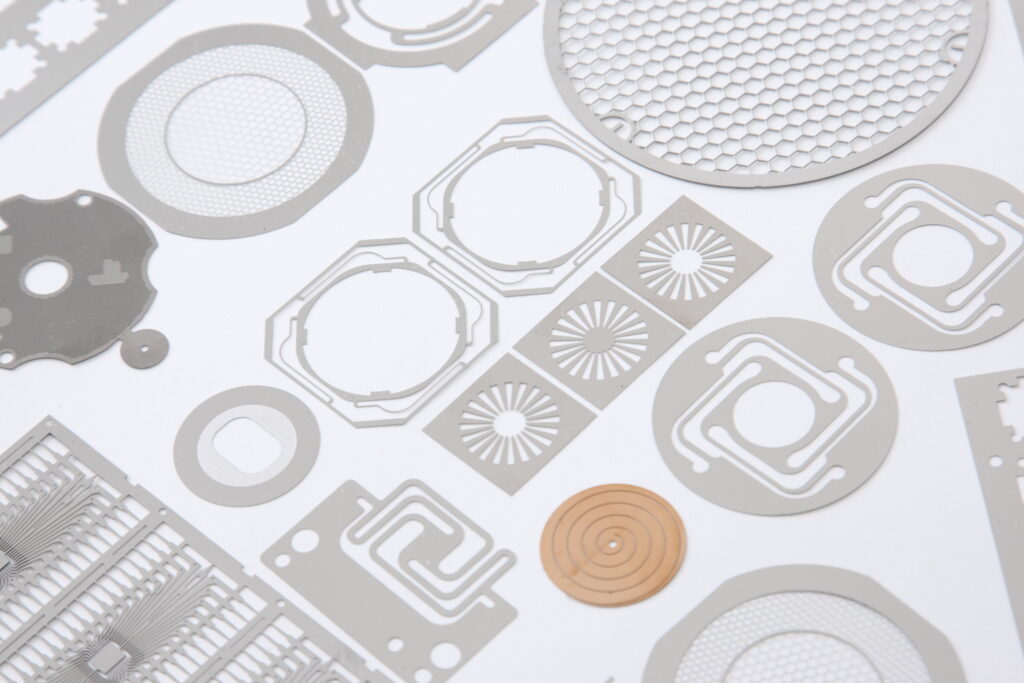

Photo Etching: Photo etching technology is the process of using corrosive chemicals liquid to melt the specific areas on a metal sheet, and forms precise, unique and complex metal parts. This allows for the formation of complex channel structures, enhancing the thermal dissipation efficiency with the coolant.

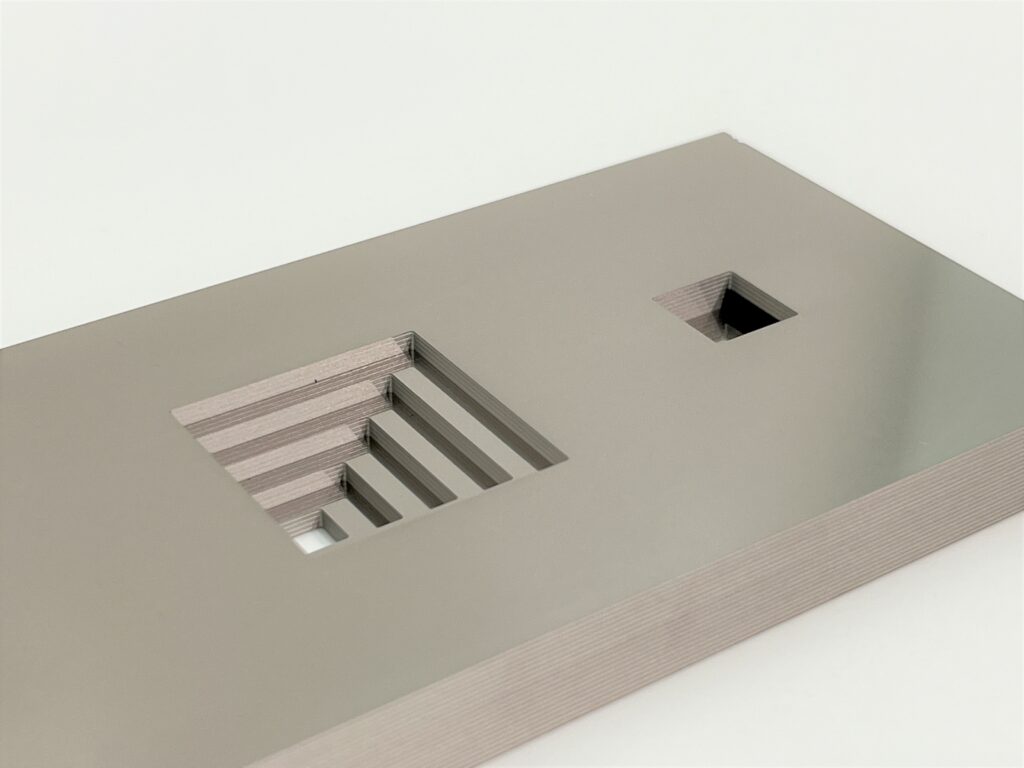

Diffusion Bonding: Diffusion bonding technology is one of bonding techniques that joints metals at atomic level by bringing their surface close together. This technique allows for creation of metal parts with complex 3D internal structures with high precision. Adhesives and spot welding are also used to bond metals commonly, but they have drawbacks such as peeling at high temperature, difficulty in cleaning, and creating gaps. The combination of photo etching and diffusion bonding technology make high cooling performance cooling plates.

Applications and Uses of Liquid-Cooled Heat Sinks

Liquid-cooled heat sinks are essential cooling technologies used in the fields of electronics and semiconductor manufacturing.

Supercomputers

Generate large amounts of heat when processing high-load tasks. Liquid-cooled heat sinks can efficiently remove heat compared with air cooling, maximizing performance and extending component lifespan while reducing system noise.

Data Centers

In high-density server environment, efficient cooling is crucial. Liquid-cooled heat sinks effectively manage temperature within data centers, ensuring stable server operation and reducing downtime risks.

Industrial Equipment

Many industrial machines generate significant heat due to high output. Liquid-cooled heat sinks are suitable for efficiently cooling these machines, helping to maintain performance and extend lifespan. Stable cooling capability in laser processing machines contributes to maintaining performance and production efficiency. In power electronics, it prevents overheating-induced failures.

Automotive Industry

(Battery Cooling)

Automotive batteries generate significant heat during extended operation or rapid charging. Liquid-cooled heat sinks are used for efficient battery cooling, enhancing performance and lifespan. Proper temperature management maximizes vehicle range and ensures safety while reducing battery degradation and maintaining long-term reliability.

Trust UPT for Custom Liquid-Cooled Heat Sink Design

UPT specializes in custom design of liquid-cooled heat sinks. Please contact us If existing methods do not meet your cooling performance needs or if you face challenges with low design flexibility and product integration.