Small / Thin Microchannel Heat Sinks with Photo Etching and Diffusion Bonding Technology

As electronic devices get more advanced and compact, their power density continues to increase, and the thermal solution comes more important. Effective heat management is crucial for ensuring product longevity. Now the small / thin heat sink demands increase to solve these issues.

What are Small / Thin Heat Sinks?

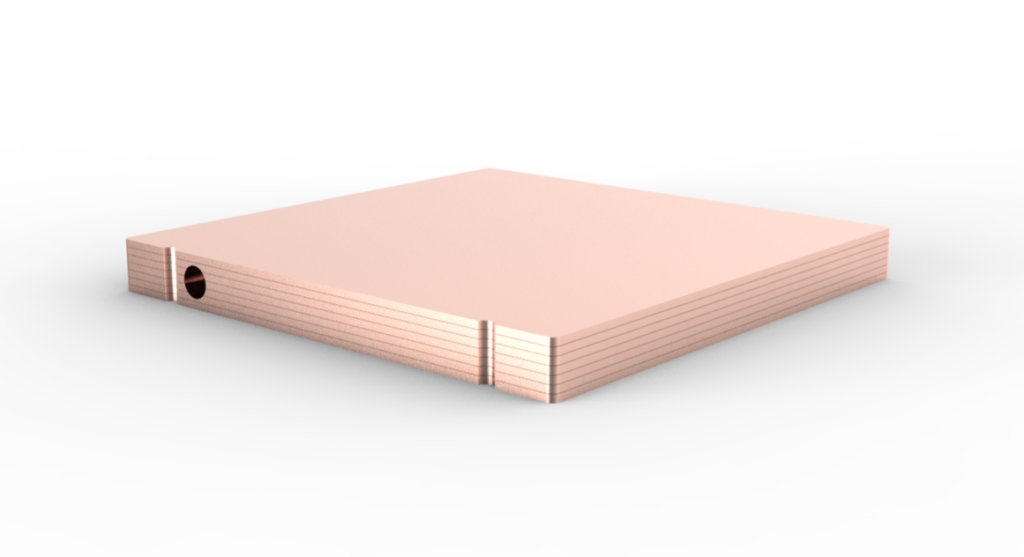

Small / thin heat sinks are cooling components designed to fit into limited spaces while providing efficient heat dissipation. These heat sinks are specially engineered for cooling small, heat-generating electronic devices, offering exceptional cooling performance despite their compact size. These heat sinks enhance the performance and durability of the devices. Such heat sinks are made possible by advanced materials and precise manufacturing techniques, which enable to create intricate internal channel structures that maximize thermal conductivity in limited spaces.

UPT’s Core Technologies Used in Small / Thin Heat Sinks

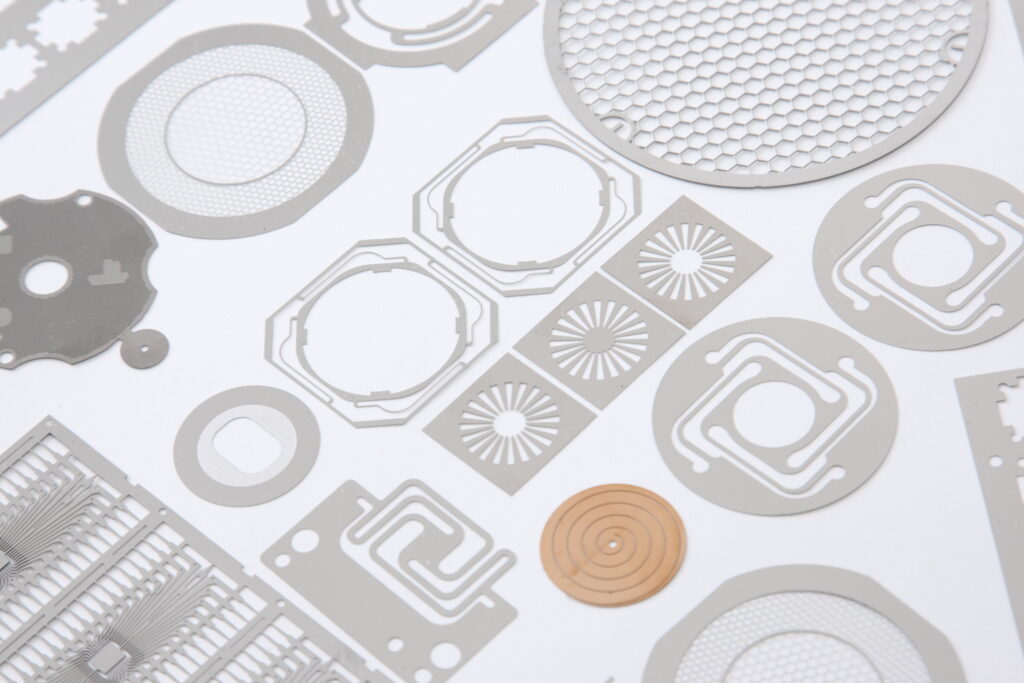

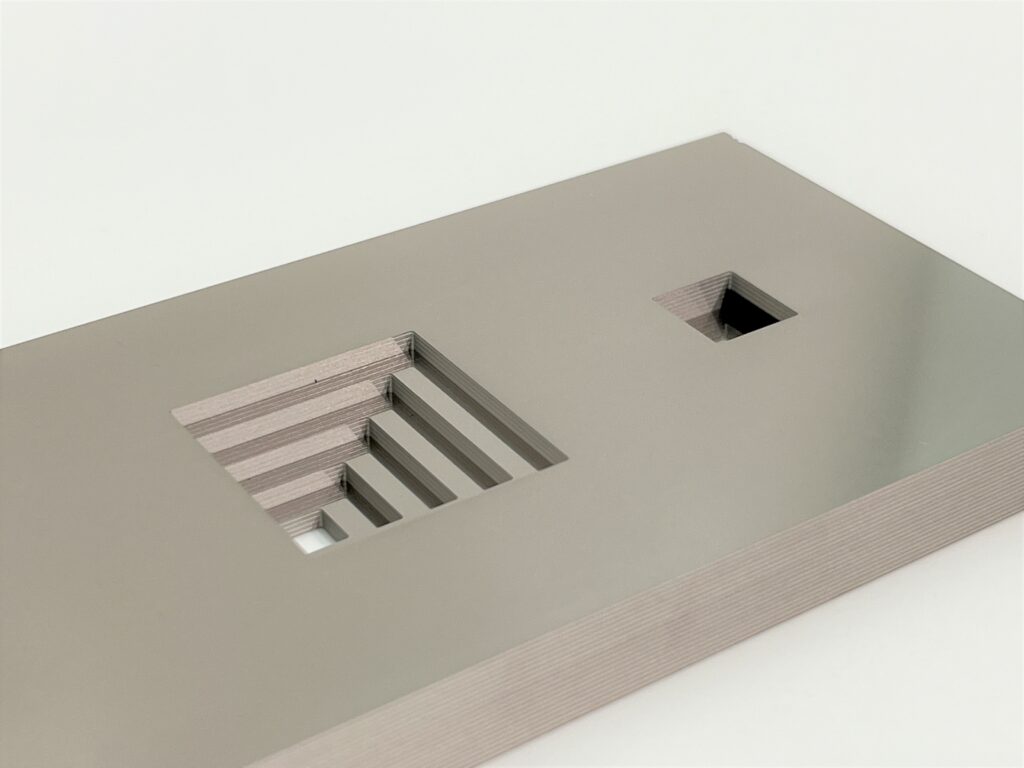

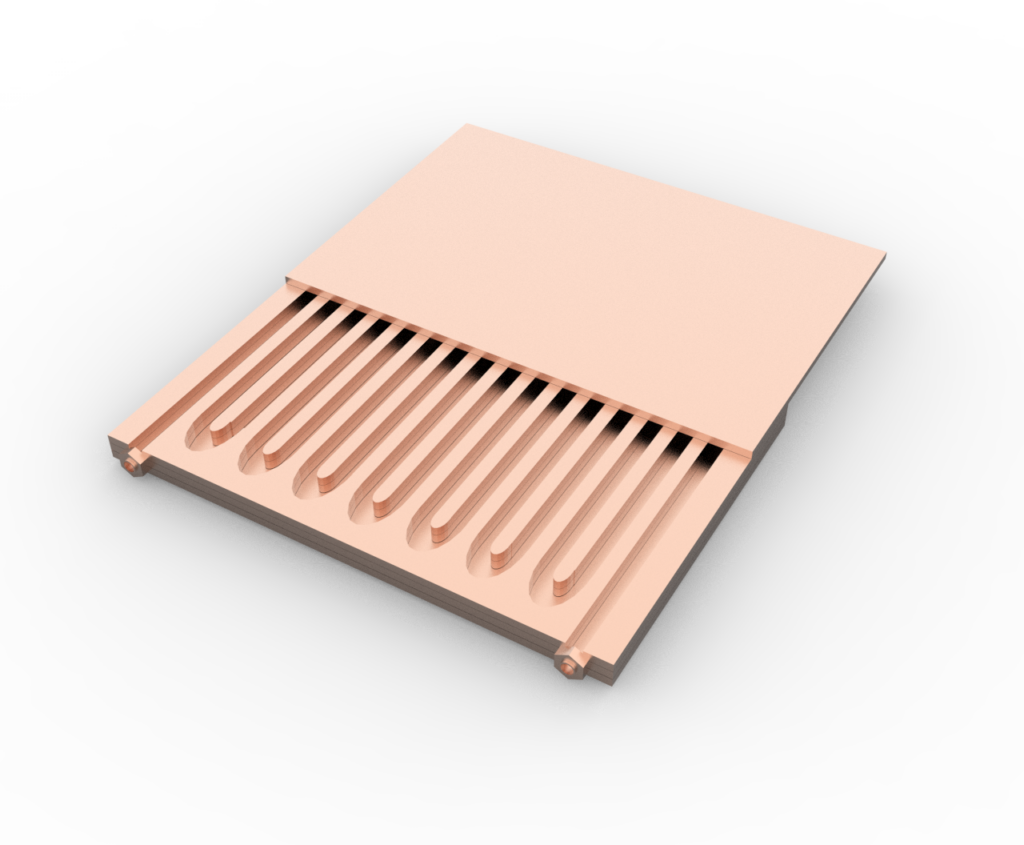

UPT designs high-performance microchannel heat sinks by combining key technologies, photo etching and diffusion bonding technology.

- Photo etching technology: Photo etching technology is the process of using corrosive chemicals liquid to melt the specific areas on a metal sheet, and forms precise, unique and complex metal parts. This allows for the formation of complex channel structures, enhancing the thermal dissipation efficiency with the coolant.

- Diffusion bonding technology: Diffusion bonding technology is one of bonding techniques that joints metals at atomic level by bringing their surface close together. This technique allows for creation of metal parts with complex 3D internal structures with high precision. Adhesives and spot welding are also used to bond metals commonly, but they have drawbacks such as peeling at high temperature, difficulty in cleaning, and creating gaps. The combination of photo etching and diffusion bonding technology make high cooling performance cooling plates.

Similar Products

UPT has other thermal management products designed for heat dissipation in compact electronic devices.

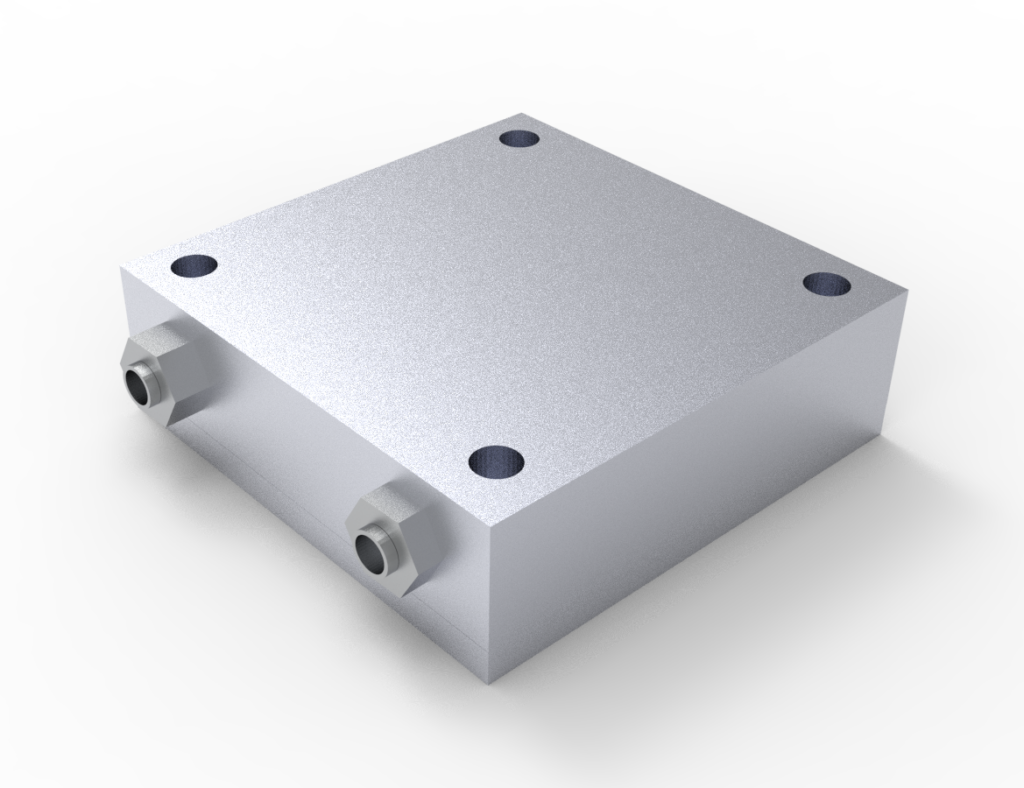

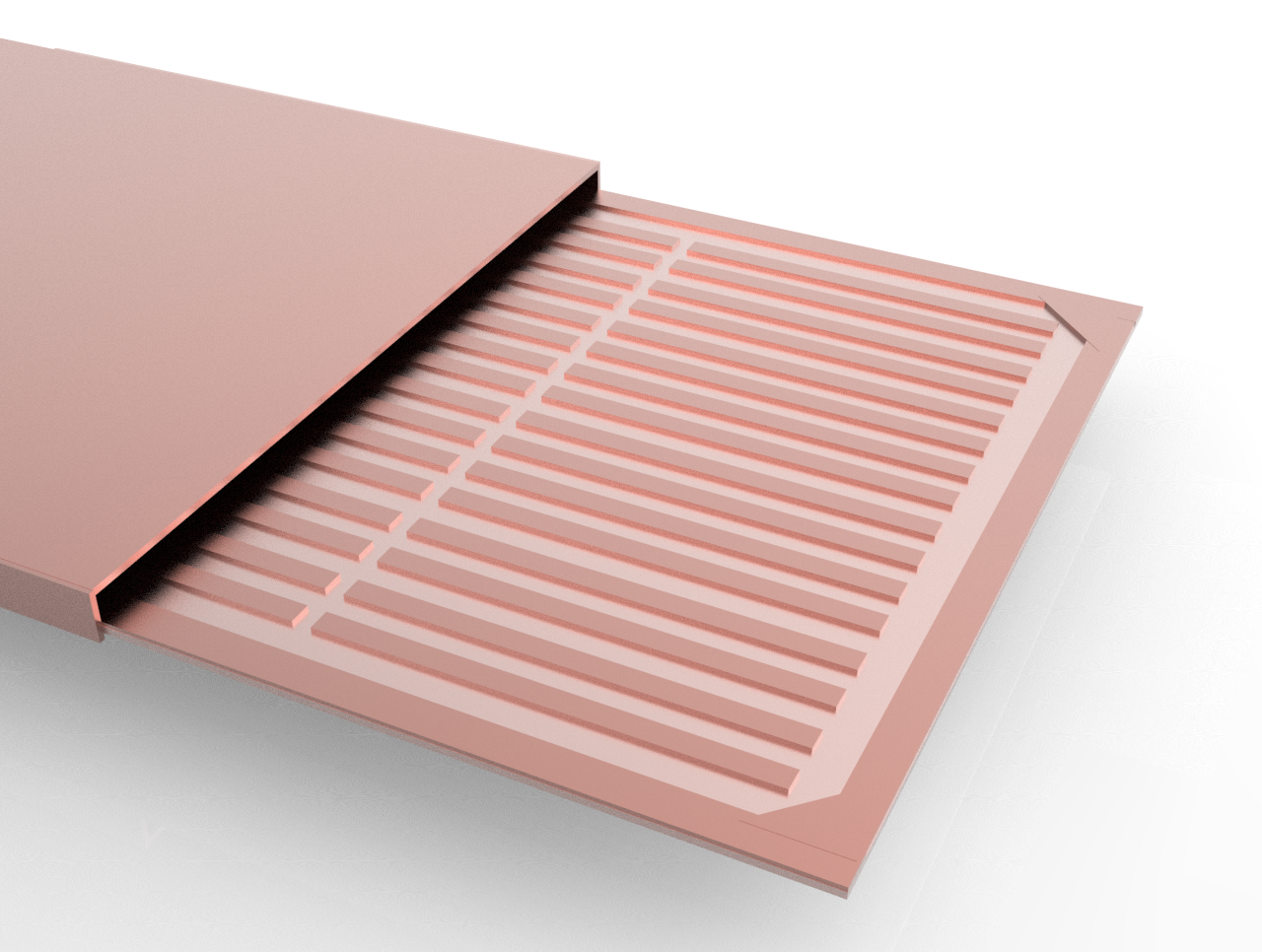

Liquid Cooling Plates

Liquid cooling plates are critical thermal management devices for electronic devices and semiconductor devices. UPT maximizes the thermal management capabilities of these devices with the combination of photo etching and diffusion bonding technologies.

Liquid-Cooled Heat Sinks

These cooling devices efficiently remove heat from high-performance components in electronic devices and computers. UPT enhances the heat dissipation capabilities of these devices through the combination of photo etching and diffusion bonding technologies.

Compatible Thermal Conductive Devices

Vapor chambers and thermal conductive sheets are often used with heat sinks to optimize thermal management. These combinations facilitate the efficient transfer and dissipation of heat, thereby maximizing the cooling capacity of the heat sink.

Vapor Chambers

Applications: PC, Tablet, Smartphone

Advantages: Thin, High thermal conductivity

Disadvantages: Large (hard to fit in small devices), High cost

Heat Dissipation Sheets

Advantages: Affordable, Easy to purchase, Versatile in application, Adjustable in

height to fit uneven surfaces and fill gaps between the heat sink and the target object

Disadvantages: Low thermal conductivity

Contact Us

UPT offers custom-designed heat sinks. Please contact us if current devices do not meet your desired cooling performance.