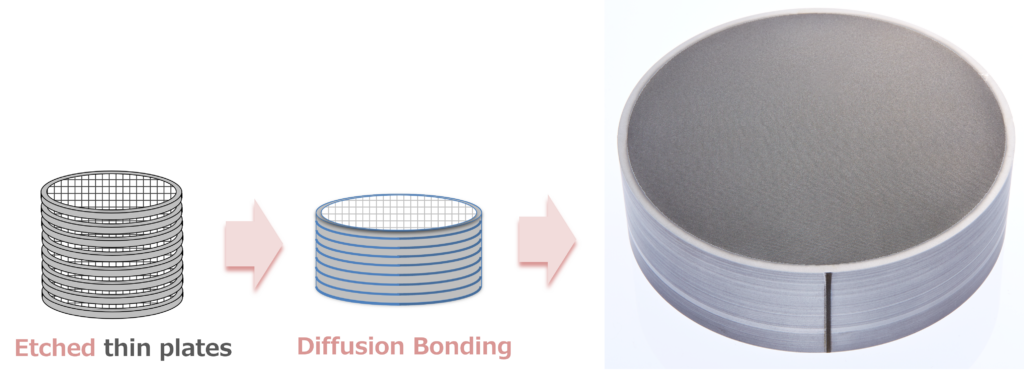

The 3D microporous metal filter created by etching and diffusion bonding

Filters are used in a variety of products, and the demand for filters is increasing every year. Especially the metal filters are increasing dramatically. The advantage of metal filters are their washability (can be used repeatedly) and durability, and environmentally friendly. Examples use case are coffee maker filters, headphone filters, flow meters and airflow systems used in industrial equipment, and air conditioner filters used in automotive market.

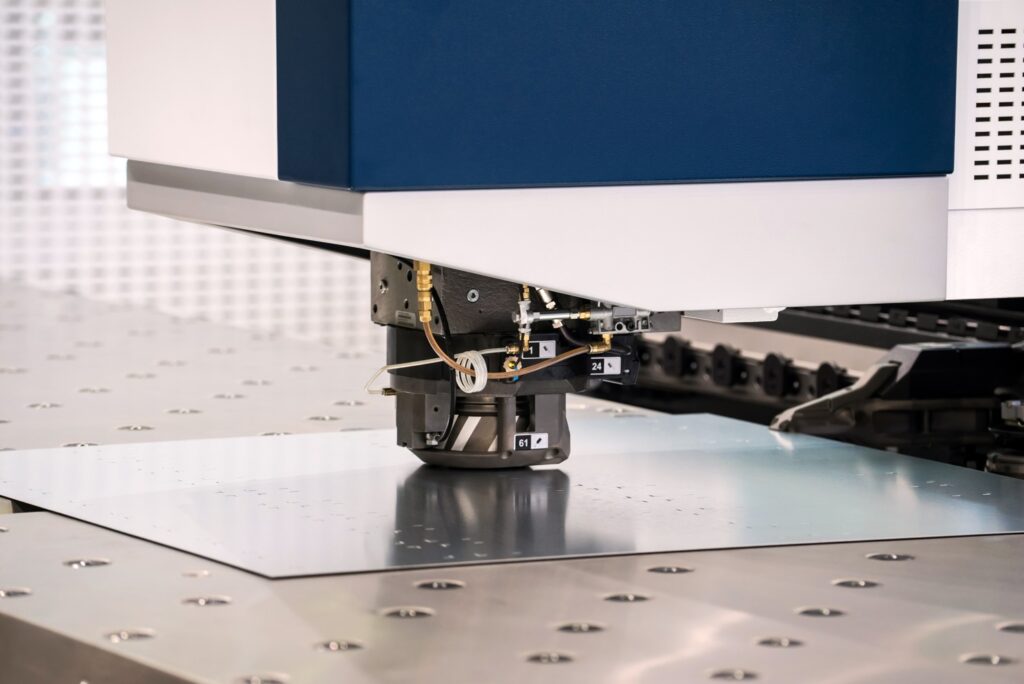

There are various methods/technologies of manufacturing metal filters, such as electroforming technology and stamping technology, but UPT provides “etching + diffusion bonding” to achieve this. For example, UPT can create three-dimensional shapes by stacking 1,000 sheets of 50 µm thick metal mesh with 100 µm holes, making it possible to manufacture extremely high-precision, high-aspect filters. Another advantage is flexible design.

The maintenance of metal filters can be done by washing, so they have less environmental impact than other materials. UPT offers the entire process from the prototype stage (Small volume)of the filter to mass production(High volume).

Issues of Non-Etched Filters

Wire Mesh Filters

Low cost for Mass production, but the running costs is high because the wire mesh filters are not high reliability and quality.

Stamping Technology

Expensive molds. Large hole diameter and pitch.

UPT Proposal

UPT offers the Union Filter® by using the “etching + diffusion bonding” process. It’s the solution to the high-precision filtering requirements of consumer and industrial market.

Advantages

- Low Cost : Excellent running costs, including maintenance, and low initial cost.

- High filtration performance : Achieved by microporous metal foil laminated structure.

- Excellent design : Process the filter part and the external part (frame) together at same time.

Success Story

- Material: SUS304 _ 0.05mmt

- Specification:φ 0.1mm hole Mesh

- Thickness: 1,000 sheets

Union Filter® Values

Value 1

The Initial Cost is Only $500.

The initial cost for “Etching + Diffusion Bonding” is only the printing plate. You can try out the ideal filter design for an initial cost of around $500.

Value 2

Strong Structure for Deformation

Minimize the deformation by using advanced

diffusion bonding technology.

Value 3

Flexible Design

The filter part and filter frame(external) are formed simultaneously by stacking the thin metal plate.