Union Tray®

Union Tray® High-precision metal products made by "etching + diffusion bonding"

Our Union Tray® is made of multiple layers of metal sheets they are bonded together at the atomic level by diffusion bonding. This enables the formation of an ideal cavity, which not only stably holds tiny electronic components in the correct position, but also dramatically increases the production efficiency of shaking in and out components. Since it is made of metal and has magnetic properties, it can be easily fixed to metal enclosures and has high durability, which is beneficial for long-term use. It can also be used as a transport tray for moving between processes, such as cleaning and sputtering processes after fixing. Cleaning and maintenance can also be performed, making it a solution suitable for SDG's that can be used for a long time.

Issues with machined products

Quality Issues

There is a limit to the number of complex shapes that can be produced, and there is not much flexibility in design. Ideal tray molding is not possible.

Not suitable for narrow pitch molding.

Price Issues

High cost. Deburring is required. One-by-one process costs more. Manufacturing method that is difficult to achieve mass production effect.

Proposal

We propose the "etching + diffusion bonding" Union Tray® as a high-precision metal tray necessary for electronic component manufacturing processes.

Advantages

- Contributes to highly functional and reliable manufacturing processes.

Dramatically increases production efficiency. - High cost performance by manufacturing in bulk quantities.

- Quick delivery is possible, which enables early confirmation of the actual process.

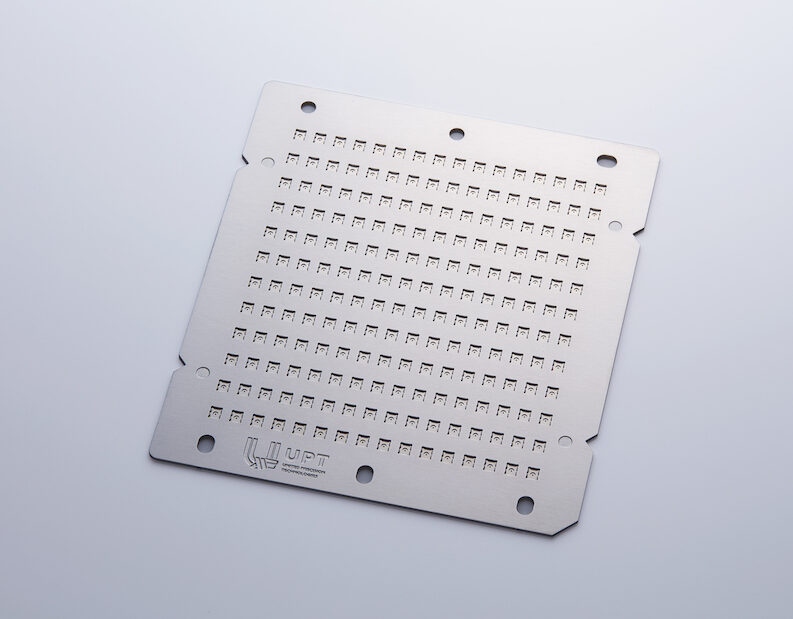

Success Story : Swing jig for electronic components

| Material | SUS304 |

| Thickness | t0.8㎜(t0.2㎜×4 layers) |

| External dimensions | 80㎜×90㎜ |

| Number of cavities | 12×14(168) |

| Hole dimensions | 1st layer □2.1㎜×2.5㎜ 2nd layer □1.7㎜×2.1㎜ 3rd layer Φ0.15㎜ 4th layer Φ0.25㎜ |

Value1

The jig design integrates the functions required for electronic component manufacturing processes that require high precision and high functionality

The "etching + diffusion bonding" process enables us to incorporate into our designs dimensional accuracy and functions that were previously limited to machined products.

Value2

Ideal for cut-and-try.

Excellent cost performance.

The initial cost for Union Tray® is only the cost of the printing plate. It is a solution that has many advantages for processes that are created by cutting and trying until the final shape. Since there is no need for secondary processes such as deburring, the larger the quantity produced at once, the higher the cost advantage.

Value3

The impact of quantity on delivery is minimal. We will manufacture the product with a delivery date that satisfies your needs.

Unlike the process of cutting metal sheets by machine, this method is superior in mass production, so we can meet the demand for more than 10 pieces with short delivery time.