For the final tuning/adjustment of tolerances and cumulative errors

Fine tuning of tolerances and accumulated errors

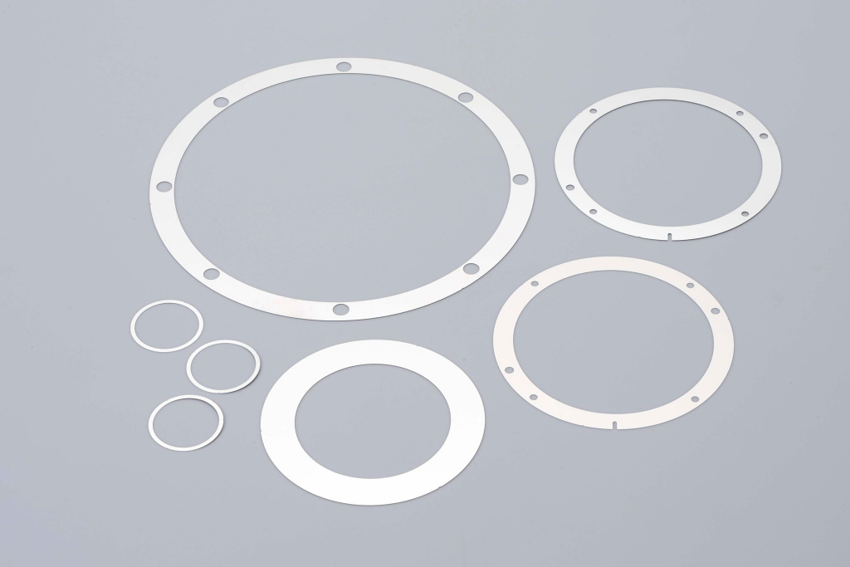

UPT offers new Shim Spacers solution which is the ring shim spacer for the optical instruments.

There are many cases to be required the fine tuning/adjustment in case that the tolerances or cumulative errors are occurred during assembling the products. The shim spacers are able to be solved this errors.

Particularly in micro precision machinery, it is required the micron level adjustment. In general, it is difficult to make the shim spacer for these application because there are many combination of material and thickness, and additionally it would be required the BLACK surface treatment to prevent the suppress/diffuse the right.

UPT offers the Shim spacers to solve these kind of issues by using our own photo-etching and surface treatment technology.

Issues of Non Photo Etching Technology

①Stamping Technology

The Stamping technology is cost effective solution for large mass production products. However there are various problems to be solved, especially in manufacturing precision shims.

- High cost for small Q’ty

In the case of a few prototypes or a small lot,the total cost becomes large. - Burrs and distortions

The surface of the processed area will be covered with something like dross and debris,which are characteristic of laser technology. - Deformation, warping and distortions by heat

Occur the deformation, warping and distortions by heat.

②Laser Technology

The Laser technology is suitable for small-lot productions because it does not require high cost molds, however it has various problems.

- Slow processing time

Compared to photo etching and stamping,the processing speed is slow and lead time become long. - Burrs, dross, debris, and distortions

Since the process is done by applying force,the burrs and distortions are occurred. - Hard to handling ultra-thin materials

It is difficult to apply force to ultra-thin materials such as 4μm thickness, which UPT can support.

UPT Proposal

UPT offers the precision shim spacer by using the photo etching technology that allow to deliver ultra high-definition finishes inexpensively and speedily.

Advantage

- No need the expensive molds, UPT use the low cost masks (master plates)

- There are no burrs, deformation, distortion, dross, or debris in the product after processing, because it is not the technology by applying force or heat to the base material such as stamping and Laser technology.

- Support all kinds of materials such as stainless steel, copper, brass, iron, aluminum, titanium, magnesium, etc.

- Support the black surface treatment to the entire product, including the sides, after processing, light reflection can be suppressed. (*Please consult us for the material)

Success Story for Optical Components

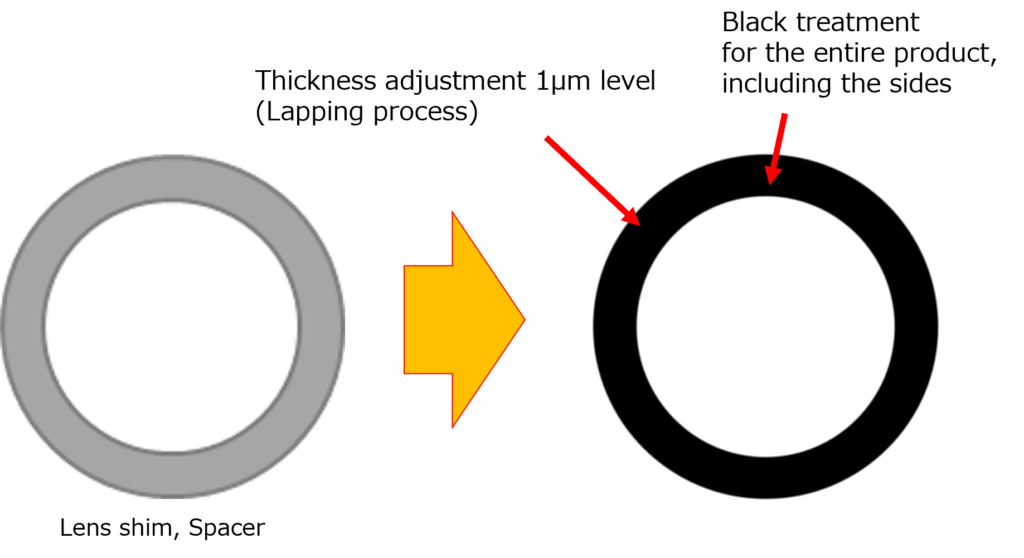

Requirement : Need to control the spacer thickness in several microns order and suppress the light.

Select the most suitable material and plate thickness from our extensive material inventory in increments of 5μm

※In this case, the material is SUS304.

After the etching process, the thickness of the plate is further fine-tuned in 1 µm increments by the lapping process. Finally, an ultra-thin black surface treatment is applied on product.

Key Values of Shim Spacer Production by Photo Etching Technology

Value 1

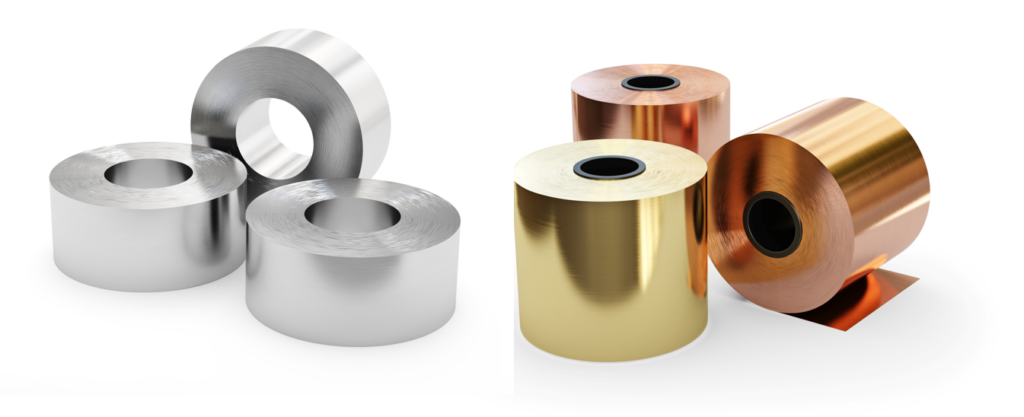

Wide range selection of materials and its thickness.

UPT supports wide range selection of materials, such as stainless steel, copper, brass, iron, and aluminum. In terms of stainless steel, we have materials in increments of 5μm thickness. And UPT also supports Titanium and magnesium.

Value 2

No need expensive molds. And UPT supports the custom design from one piece.

UPT supports the custom design products with short lead time because UPT uses low cost film masks.

Value 3

High-definition finish goods with no burrs, deformation, distortion, dross, or debris.

UPT solution does not have the burrs, deformations, or distortions because we use the photo etching technology.(No heat/Force) Also, no dross or debris is generated, so customer does not need to additional work to remove them.