Union High Speed Sheet: UHSS®

Upgrade the evaluation performance and durability without changing the equipment you have now.

5G, the Next-Generation High-Speed Communication Network.

All the communication equipment, such as mobile data communication devices, and communication modules that support 5G, and the high speeds of these devices, are supported by small and high-performance electronic components. We introduce a new connection terminal or contactor using our technology, UHSS® (Union High Speed Sheet), it is for evaluation and inspection processes of electronic component manufacturers who respond to such various demands in the world.

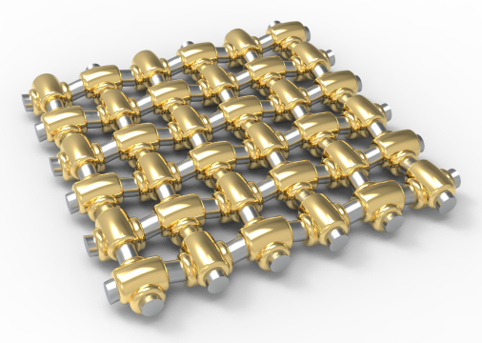

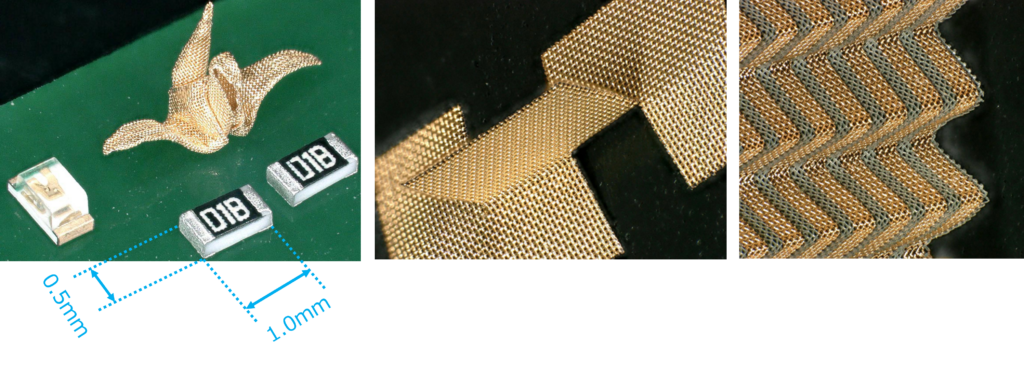

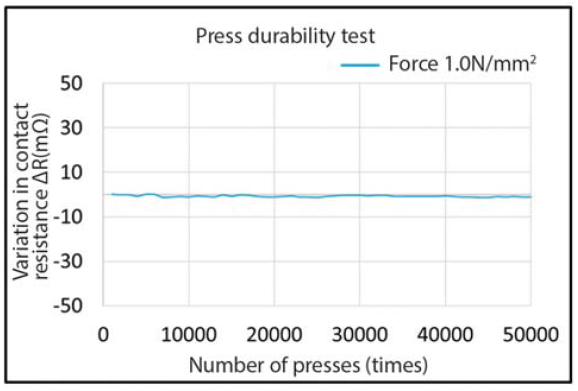

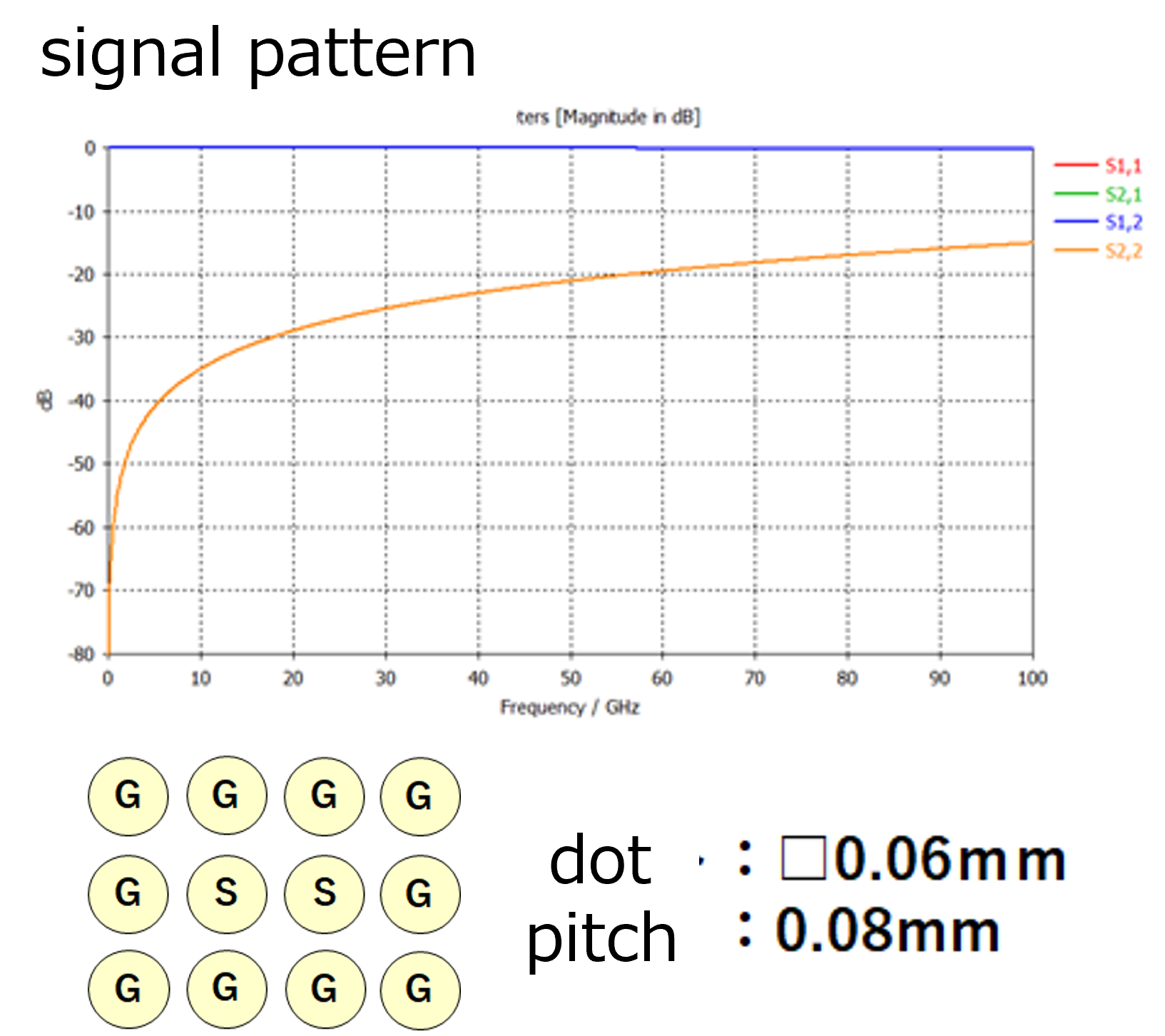

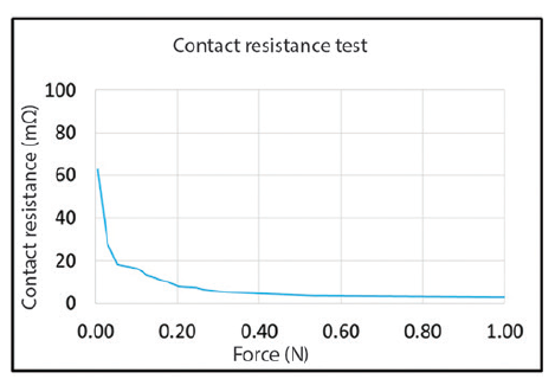

The UHSS® is a new type of conductive sheet made of special woven fibers and plated through both sides. Its features include flexibility to maintain continuity even when bent, high customizability and high-speed signal characteristics capable of 100 GHz or 200 Gbps. The load required for energizing is 1N/㎟. 50,000 times high durability is also provided. (According to our own research)

Please consider this as one of the best solutions for conduction of electronic components, which are becoming smaller and more powerful.

Physical Challenges of Probe Pins

・The target device and pad are extremely small, the positioning accuracy is required very precisely.

・During probe pin measurement, there is a high possibility that dust will get mixed in with the probe moving part, so it cause the sliding failure. It is physically difficult to manufacture short probes by machining ≒ high cost.

Electrical Challenges of Probe Pin

The probe pin has many contact points inside, and the conduction path is likely to change at each touchdown, so making it unstable.

As the number of tests increases, instability of characteristics becomes more apparent.

The inductance value is high due to the long dimension that hits the transmission path of the probe, and transmission loss is a concern.

Proposal

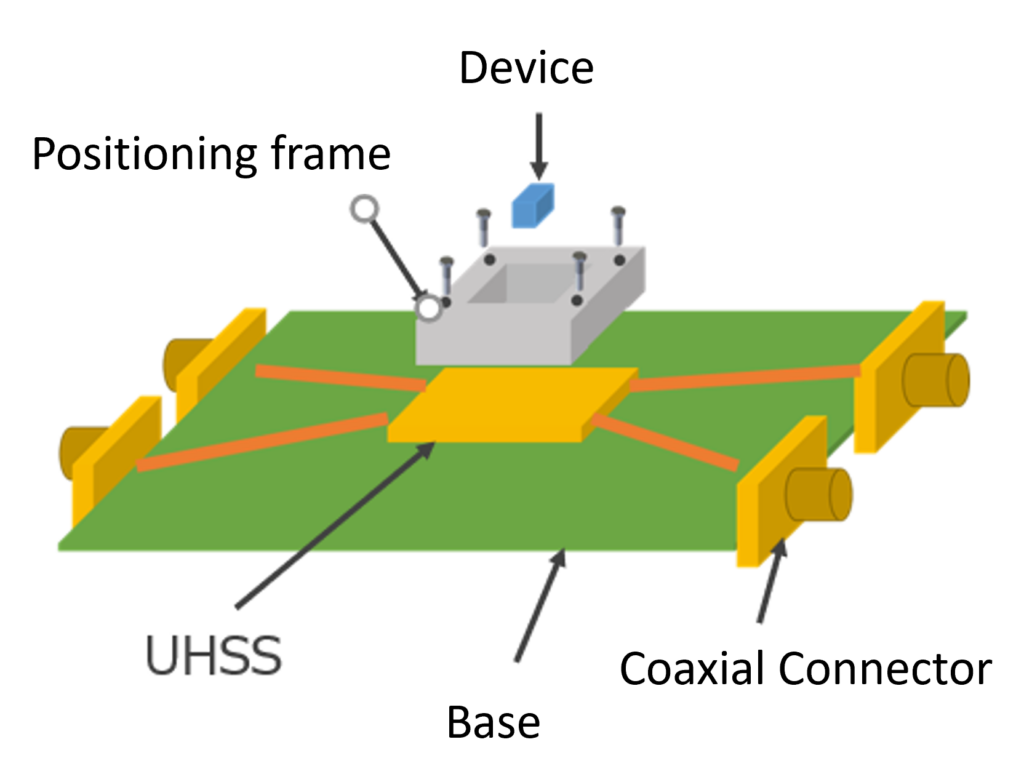

We propose UHSS® as a connection terminal to the board for evaluation, measurement, and inspection of ultra-small devices.

Value

- Since it is an anisotropic conductive sheet, severe positioning accuracy is not required to obtain current flow. ※Target device and substrate pad must be aligned

- Improves the yield of the inspection process because of stable connection quality.

- Replacement is very easy.

- Excellent cost advantage over probe pins.

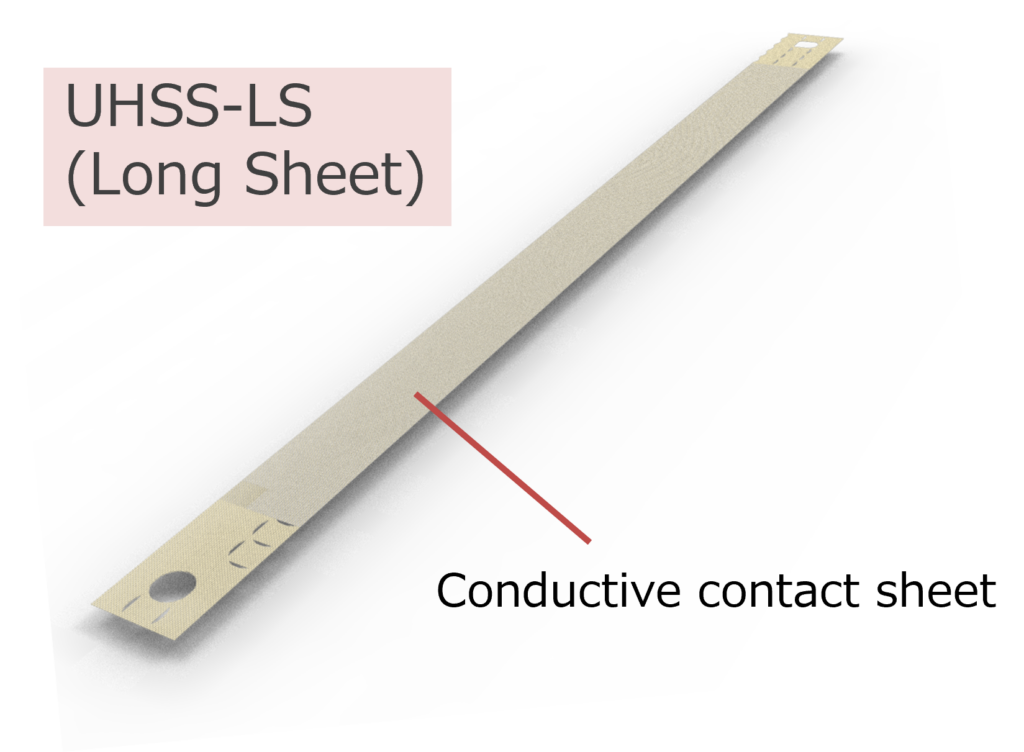

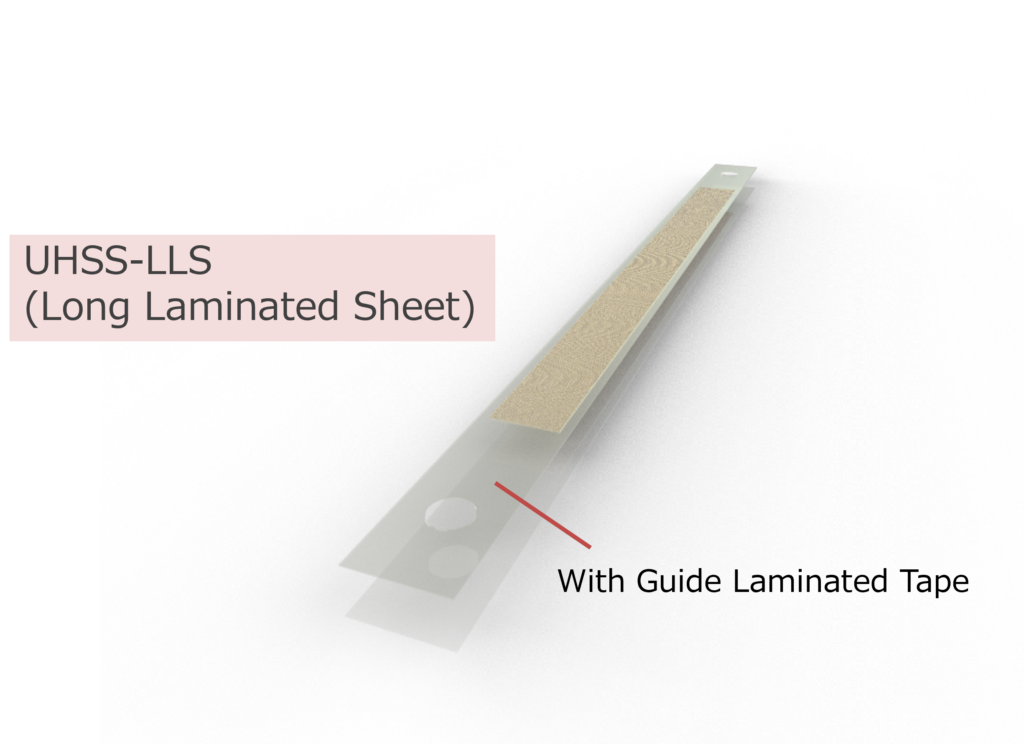

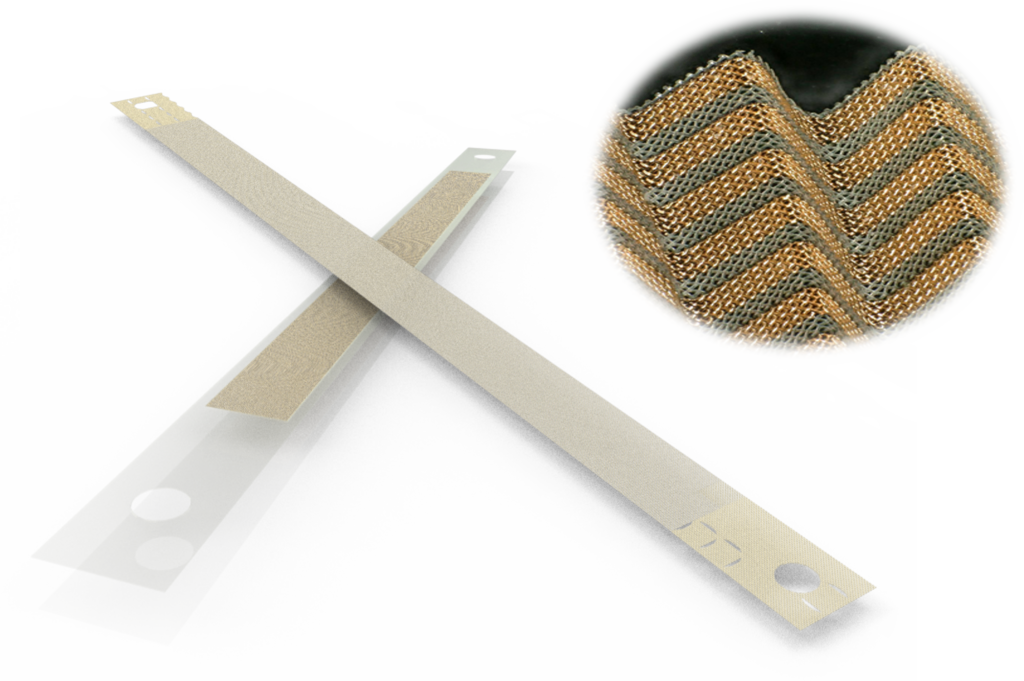

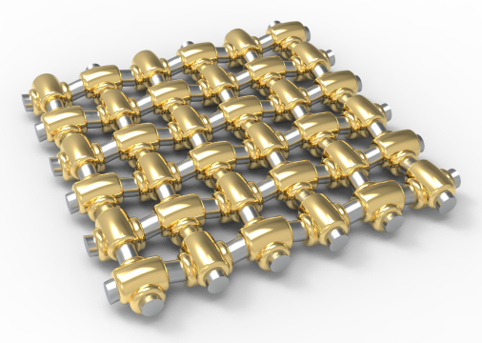

UHSS-LS / UHSS-LLS Product Overview

Improves contact durability and high-frequency for mass production and final testing of electronic components. The sheet shapes can be customized to fit the shipping test equipment and facilities for electronic components. And guided tape shapes such as the one shown below in the image can also be accommodated.

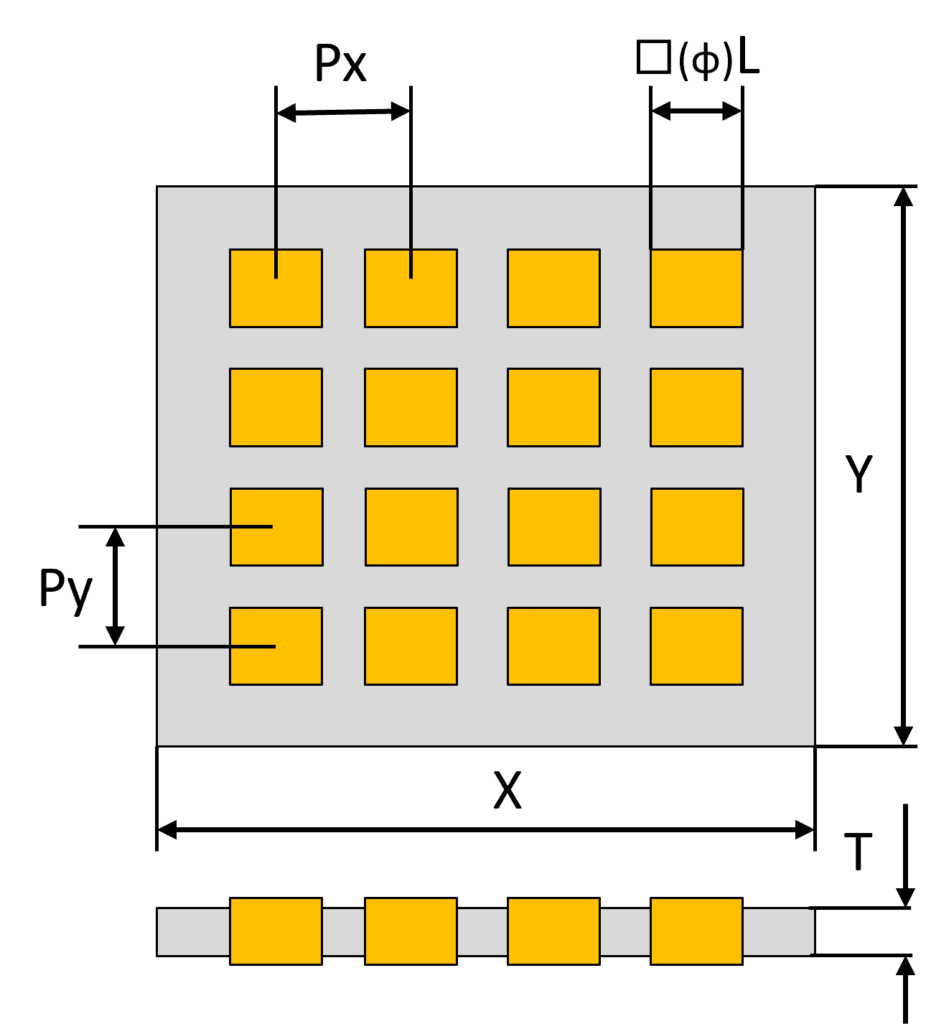

UHSS® Product Features

Insulater: High-performance plastic fibers

Features

- 0.05mm thickness with double-sided conductivity specifications

- Bendable 180°

- 3A current rating

- Fine pitch/ mini contact points (Pitch: 0.08mm~, Contact point □0.06mm~)

Specifications

- Rated current: 3A/ dot (per contact)

- Transmission speed: 200Gbps@-1dB

- Touchdowns: 50,000 timeess

| Dimension | Spec |

| Pitch (Px) | 0.08mm~ |

| Pitch (Py) | 0.08mm~ |

| Thickness (T) | 0.05mm~ |

| Electrode size (L) | □0.06mm~ |

| Size (X) | 5.00mm~ |

| Size (Y) | 5.00mm~ |

- You can make an origami crane with UHSS®

- Flexible, bendable, 0.05 mm thickness, conductive sheet with double-sided conductivity

Examples of inspection enviroment

Value of UHSS®

Value①

Flexible Design

You can just insert it between conductive parts to energize them.

Also, allowing free wiring patterns as a replacement to FPCs.

Value②

Space Saving

The minimum mounting thickness is 0.05 mm, half the thickness of newspaper, making it ideal for applications where space is an issue.

The free bending process allows for conduction within a limited space.

Value③

Long Lifetime

UHSS has sufficient durability even though it is an ultrathin sheet contact. It exhibits stable contact resistance value after 50,000 times of touchdown.

Value④

High Frequency and High Current

Supports 200 Gbps high-frequency communications despite its ultra-thin profile.

Contacts arranged in 0.08mm pitch. Amazing 3A current rating per contact.

Value⑤

Low Force

The force per mm2 of sheet area is only 1N*.

※For a contact stroke of 0.01mm

Value⑥

Fine Pitch

Contacts arranged in 0.08mm pitch.